My location: USA, State of West Virginia, City of Clarksburg area.

My full-sheet LowRider 2 is now up and running (cutting is happening as I post this).

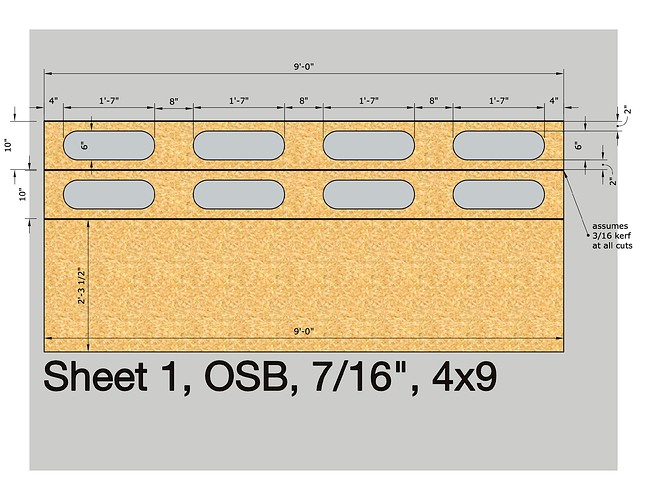

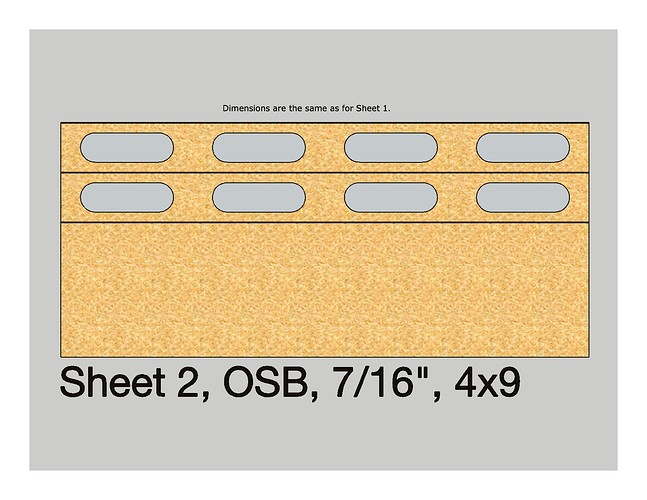

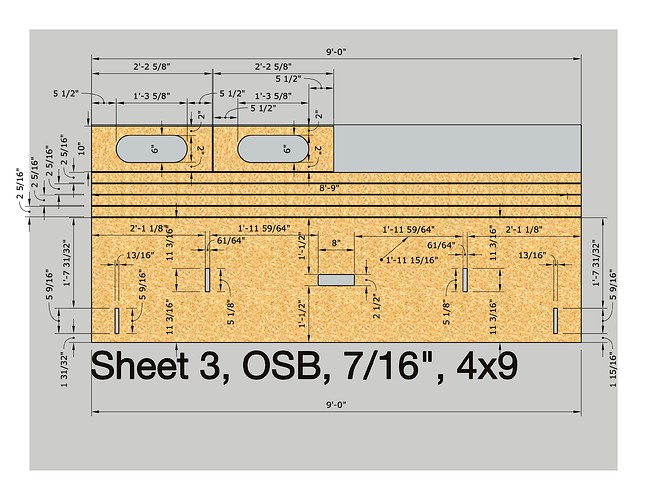

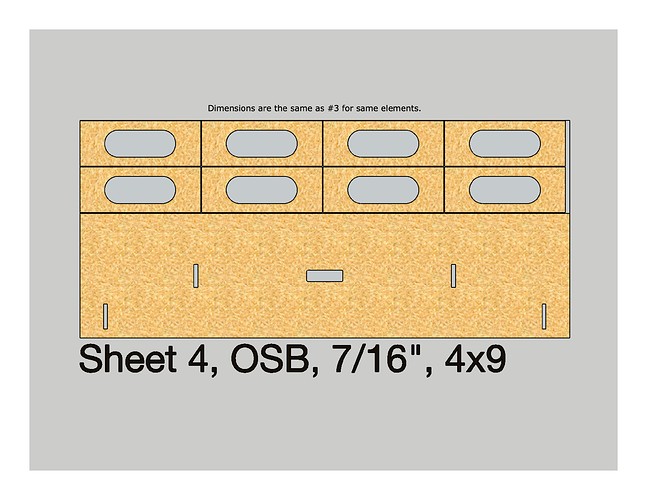

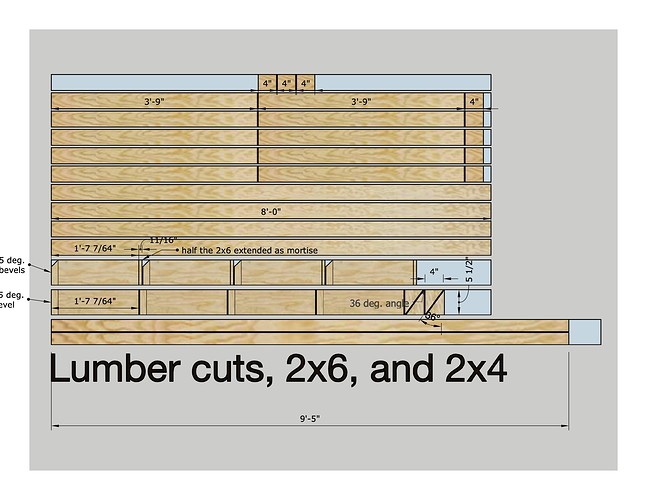

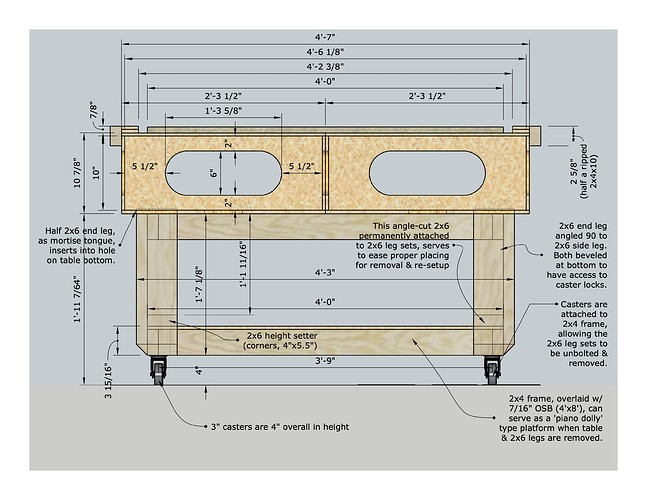

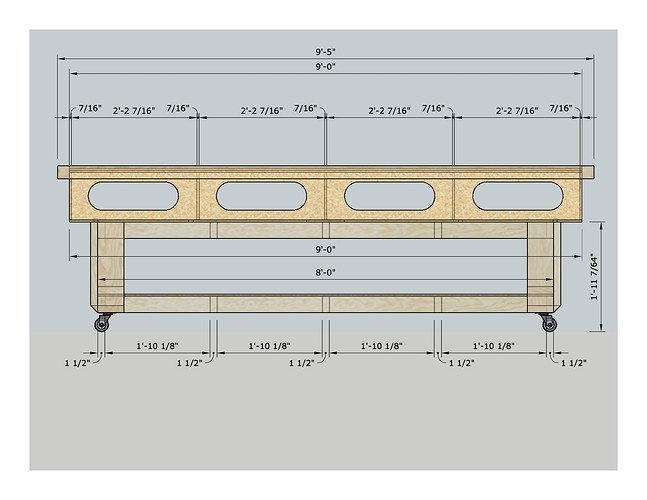

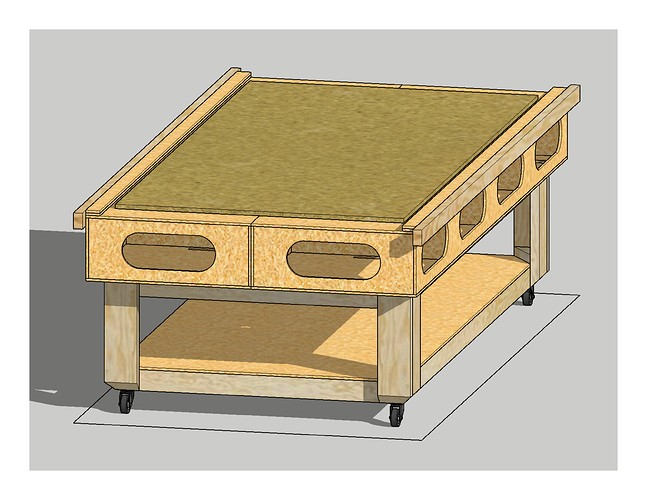

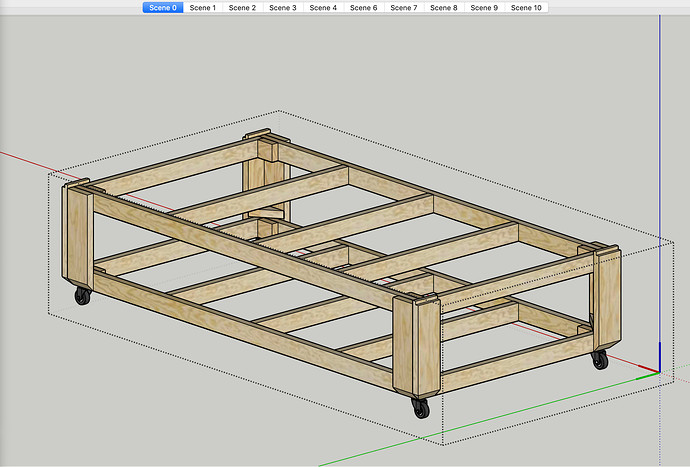

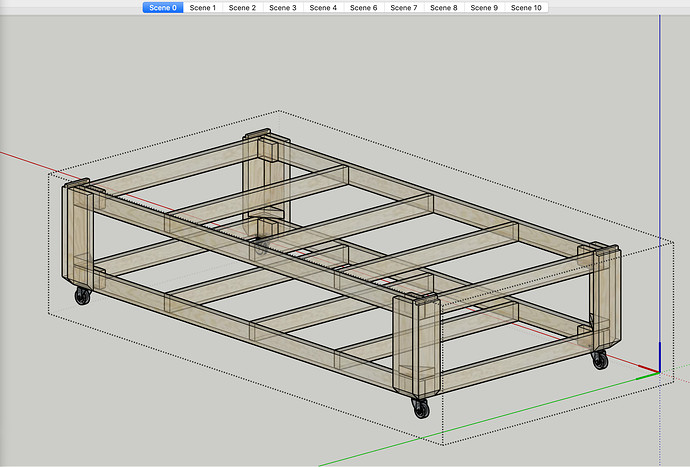

In this thread I will seek to detail both the LowRider 2 and my table build — with “budget” torsion boxes made from OBS, if you can believe it. I was trying to source materials during the period when plywood was rare and prices had skyrocketed. The sheet size and thickness I wanted could not be found locally, at all.

I will provide both pics, plan drawings, etc of the table build.

Note: Although I bought two “unistrut” metal pieces to use as side rails, my uncertainty about the proper final height for placement (because I’m relatively new to CNC), caused me to use wood side rails instead (for now), by splitting a 2"x6" with my table saw. I am somewhat glad I did that for the present time. I wound up moving the existing wood side rails twice after first installing them. Now that I am more certain/comfortable with the existing height, I may indeed look to switch the unistrut metal in instead. Side note: the two times I moved the side rails, were (1) “away from” the original plan and then (2) right “back to” the original plan. So, at least for now, the plan drawings I will show, are still correct.

I’m posting from my computer but my photos are on my phone, so I will aim to add them soon.