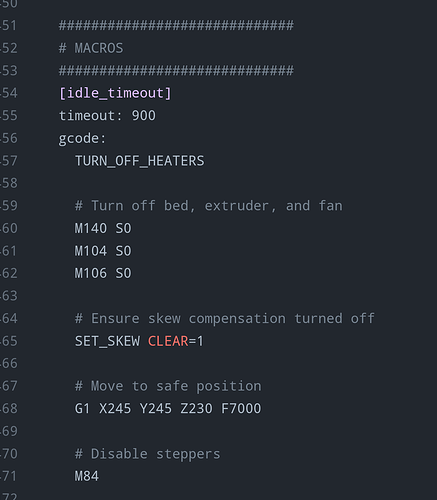

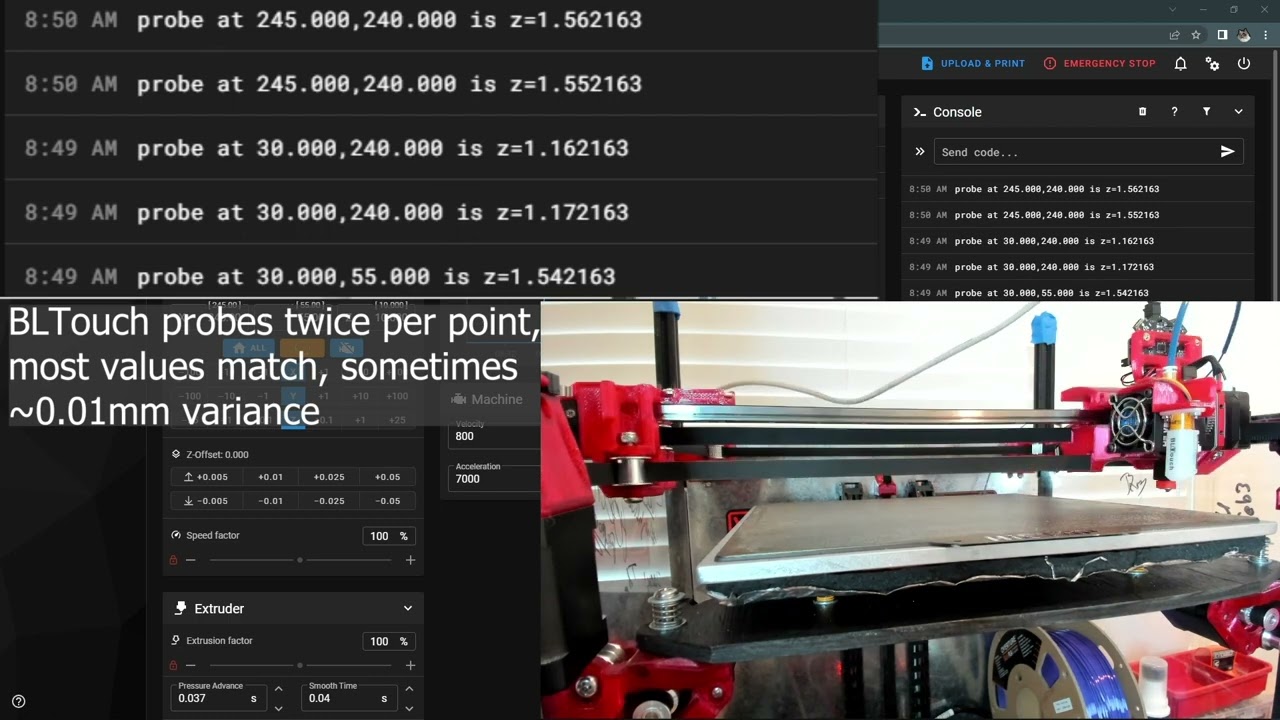

The 0.04mm thing was based on 4 start lead screws. Definitely not a factor with a belt driven Z. The idea was that with a 4 start screw 200 full steps was 8mm travel, so 1 full step is 0.04mm. By making your Z layer heights full step increments, you supposedly get more consistency. This was based off of some comparison of commanded movement versus real world movement in microsteps where there is a real world error in microsteps that roughly follows a sine wave. So micro steps are just slightly off with a maximum deviation at 1/4 step. (IIRC Full step + 1/4 will be slightly more than commanded, full step + 3/4 will be slightly less.) But a full step from any microstep position will have a real world movement that is closest to the one commanded step of 0.04mm.

Well, that’s true, they are, but the actual amounts are so tiny in comparison to the bits of squirted plastic that they really don’t make enough difference in relation to the rest of a 3D printer mechanism.

Given that with 16x microstepping, the amount commanded is 0.0025mm, and the real world error is within a few percentage point of that, it’s really not a big deal.

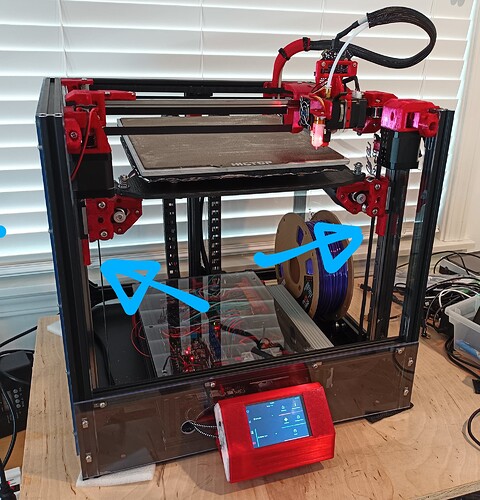

If you want to be like that about it with the MP3DPv4 (or v3, for that matter) you will want your “magic number” to be 0.16mm, so layer heights of 0.16mm or 0.32mm.