This is what I used when i put mine together and it worked well.

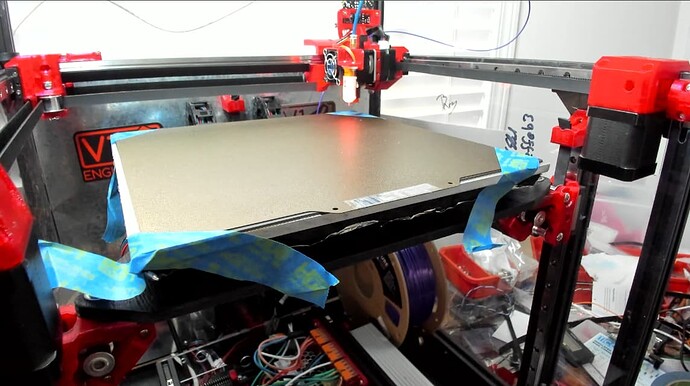

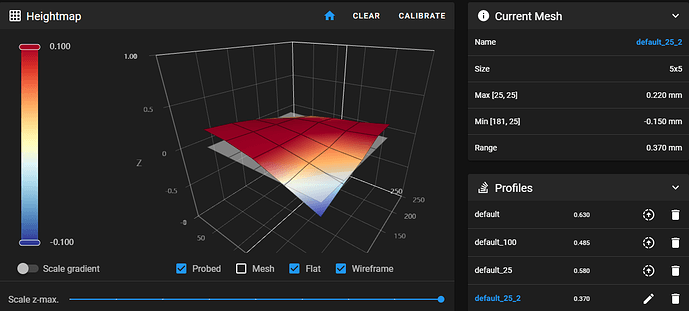

Was curious about impact of PEI on height variance while reading Jonathan’s topic. So, jankily temporarily taped PEI and magnetic layer to Alu plate…

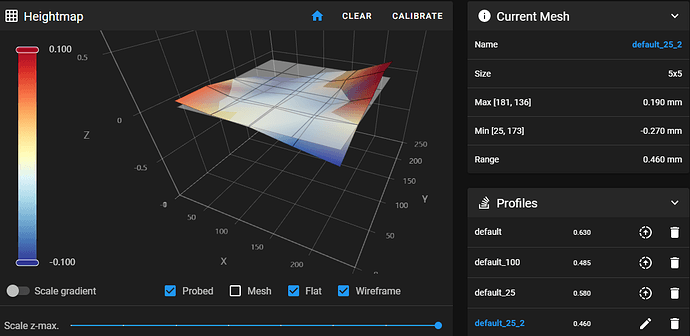

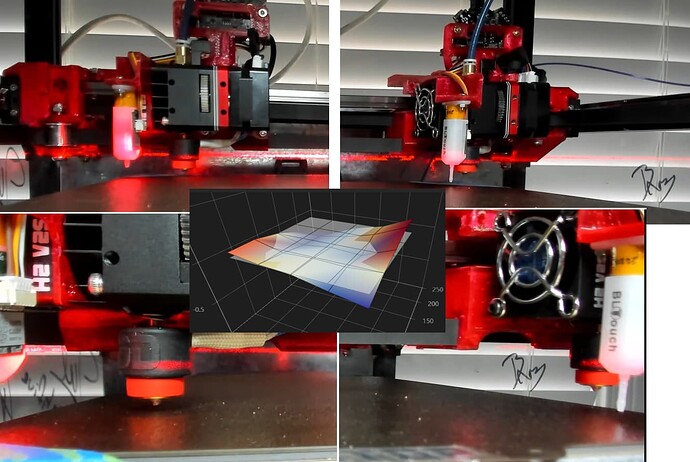

Used 4 point probing for z-tilt (instead of 3, details provided in earlier post), to help split the difference in my minor twisted setup…

Not seeing much difference relative to previous mesh calibrations.

Measured extrusion diagonals between corners, looked the same to me using a regular mm based tape measure. Double checked extrusion is straight too. All looks good enough to me, leaving things as is and moving on. Hope this info helps someone.

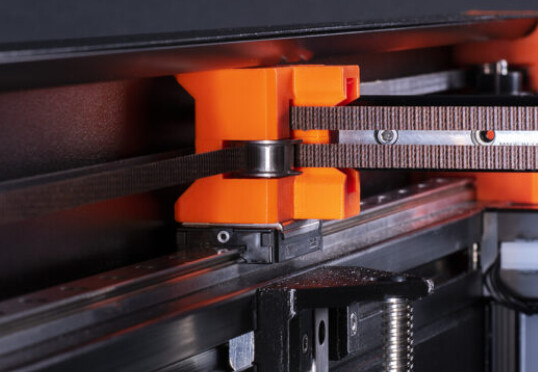

Longer term, after seeing Prusa XL at RMRRF, am curious whether linear rails on top of the extrusion would enable easier shimming/adjustments of linear rails to easily compensate for skewed/twisted frame cuts/assembly inaccuracies? Could gain additional X width too, but maybe that approach would introduce other motion challenges?

That just moves the adjustments to a different plane.

Going to the top moves everything related to XY, that also drags the Z up as well. From messing with it I did not see any advantages, unless I built a mostly metal version.

I am not really sure how I feel about the printers. For the number of builds out there, there seem to be a lot of struggles. It takes me a while to get mine dialed in but I am shooting for pretty extreme accuracy.

I am wondering if my version is fit for a wide release like this. I have nothing to compare it to, but the feedback seems to be 50/50 right now.

All three of us have the same direction of twist?

I have a 0.4 overall twist on a smaller bed so yours is more accurate than mine. With level fading that is easily compensated for in a few mm worth of print height.

Is there a badge for the most twist??? If so I think I win that one!!

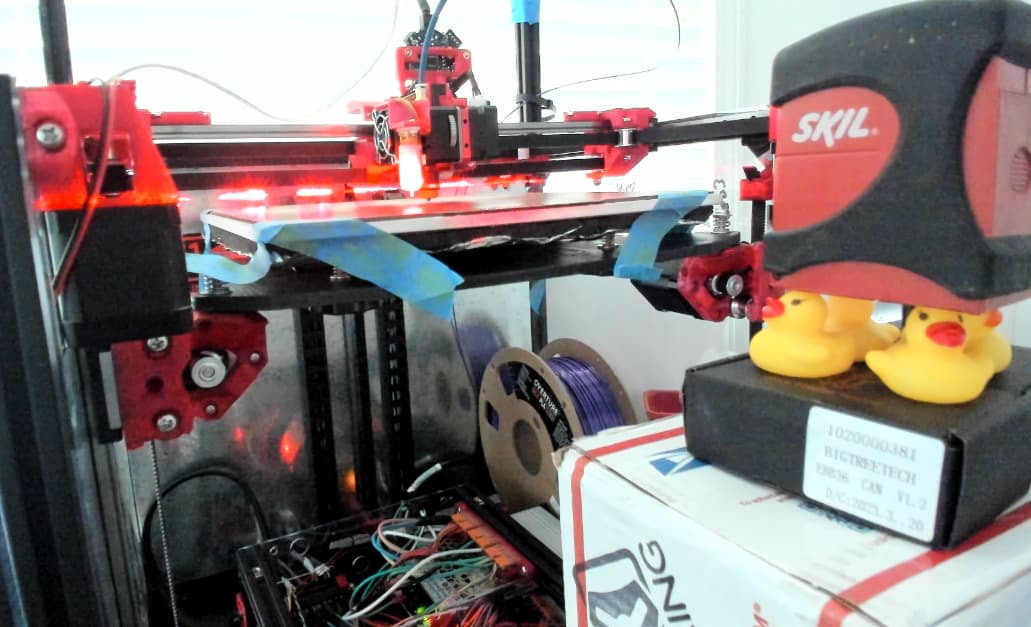

Couldn’t resist seeing if/how laser could help…

Wondered whether observing height of the laser on the hotend, and surrounding parts during moves will help isolate what needs tuning.

Note, was using a makeshift tripod, and the bench was not true level, let alone a true flat surface. Kitchen countertop (verified with a level) would have been a better surface to use.

Ideally would’ve used better quality more finely focused laser, this one’s ~10yrs old.

Ignore the right rear corner where the PEI had uplifted slightly.

The laser helped me eyeball observe small height differences where laser hits the hotend. These differences mostly correlated with the mesh. So, this info would help me focus on tuning that if I already figured my Alu/Bed surface was flat enough.

Am happy with my setup, but IF the height variance was unacceptable and seemed to be caused by rail skew/twist, thinking I’d use this approach to help figure out which Y linear rails to loosen, adjust and snug back up. Improvements/suggestions appreciated, this is new to me. Cheers!

When I build mine I measure every diagonal I can and keep adjusting until I get it as close as possible. I make sure all my rails are centered.

After that, I do the belt tensioning to get the XY prints square. After that, I do the Z prints to get the Y rails parallel. That adjustment is just letting the rails move down or loosening the screws or push them up. The screws give a ±1.5mm each way I would guess. So that lets you move one rail up and the other rail down for a full 3mm of angle or so. Typically I end up only needing to move one rail up or down and that gets me a very square cube.

So spend all your time with the frame and the diagonals. Then the test prints bring it in the last faction of a mm.

It took me a long time to figure out the adjustments but I was super concerned about a twisted or skewed Z system but it seems the three rails kinda balance each other out. So once it’s built I believe we end up tuning the Y rails to the Z system, not actually to the frame.

I guess I should look at how the Voron guys have the frame calibrations set up.

Am happy with my setup

No more issues for you anymore?

No more issues since you mentioned Mic6 is 0.381mm, cheers for that!

Am not fixing anything that needs fixing, am just tinkering and learning. Sorry for randomizing ![]()

IF the height variance was unacceptable and seemed to be caused by rail skew/twist, thinking I’d use this approach to help figure out what to loosen, adjust and snug back up.

I think the best way to use the laser would be to turn off the leveling feature and just mark two equal points on the frame so there is no chance of the level actually being the issue.

It is the best idea yet, it is hard to measure something with no solid frame of reference.

Sorry for randomizing

No no, glad to hear it.

look at how the Voron guys have the frame calibrations set up

Google/Youtube has been reading my mind/posts. They suggested I watch Steve (Voron Trident designer) calibrate a frame for one of his recent live build streams. Quite long, so here’s some related notes… In short, he measures diagonals, a lot.

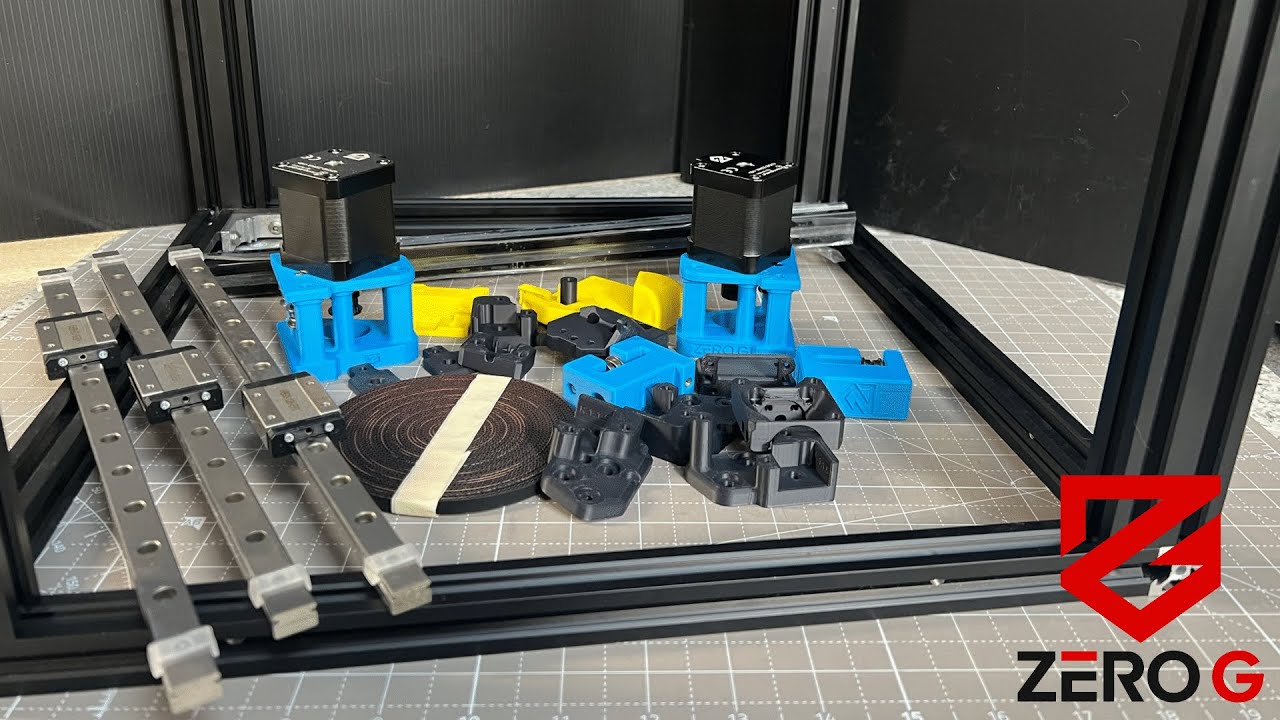

This Stream is Part 2 of a series building a ZeroG Mercury One (https://docs.zerog.one). Upgrading an Ender 5 to CoreXY Printer, not from scratch build.

Stream starts ~1:30 talking about the frame being out of square > 2mm. Cause was “square” corner brackets not being truly square. Steve fixed by grinding them square. Steve’s assembling on project mat, on a flat slab of quartz.

4:00 Consider making an extrusion touch up station with disc sander, 123 square blocks and clamps. Requires time to build, align and squaring.

6:40 Ensure chopsaw trammed and squared if using one.

7:30 Use square corner brackets, but first you’ll probably need to square them, because… quality. Steve’s were < 90 deg

9:00 Start one side, sneak up on tightening into corners, switch back and forth.

12:00 Use 5mm blind joints to secure frame better

12:30 Tap holes for belt adjustments

20:00 Use soft feet to avoid base scratching.

31:30 Uses NOGA Deburring Kit

56:00 Mounting Y linear rails to top of extrusion.

1:02:00 Linear Rail spacers (offensively lime)

1:16:00 Quick view of Right XJoint (XY truck) in Fusion 360

Stream continues with assembling other parts, not frame squaring related afaik. I didn’t watch entire stream, just skipped around indexed sections.

little late to the party, but this is my favorite pic so far:

Added magnetic base and PEI. On reflection, adhering the magnetic base much earlier in the build would have been easier. People usually adhere the magnetic base before the heater bed, which is before the Alu Bed is mounted to the mdf/ply Bed Support Plate. Following that sequence would have made it easier to press roll the magnetic layer smooth.

However, on the other hand, the dumb luck stumbled upon alternative approach I took has helped me better understand how far off true flat my Alu bed is. So, upon further reflection, I don’t know what’s the best assembly sequence ![]()

Followed Wham Bam, and Steve Builds (Voron Trident designer) guidance for mounting magnet/heater base layers. Some notes:

3:41:00 Advice: Mount magnet layer to Alu plate before bed heater. Easier to roll flat.

3:42:00 Clean with Isopropyl liquid/wipes, remove debris, dust and oil.

3:45:00 Scrub with Scotch Brite Pad.

3:50:00 Set down and adhere magnet layer. Line up side and front, press down at back, check lined up, gradually peel back, press and “Roller Press” as you work towards front. Press it good, press it real good.

3:53:00 Cut holes in magnet layer.

3:55:00 Advice: Time permitting, let adhesive cure (Wham Bam docs reco 24-72hrs…). Putting under pressure and leaving to cure is good idea, that many people don’t follow.

3:57:00 Clean Alu plate for heater bed. Same as earlier, use Scotch Brite Pad .

4:03:00 Set down and adhere heater bed. Line up sides, similar to before, gradually peel and press down as you go, ideally with roller press.

-Heater bed went on slightly wonky, so, pay attention to multiple sides while adhering, don’t overly focus on just one edge.

Adding PEI seems to have helped smooth out measured mesh heights a bit. Range 0.37mm seems pretty good, after you overcome the exaggerated perception that the visual diagram will impress upon you at first glance. Careful frame and/or Y linear rail tweaks maybe able to help improve further even.

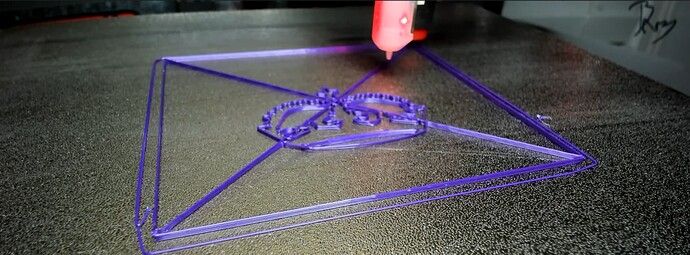

Using Bed Weld is helping my 100mm calibration crown stay put.

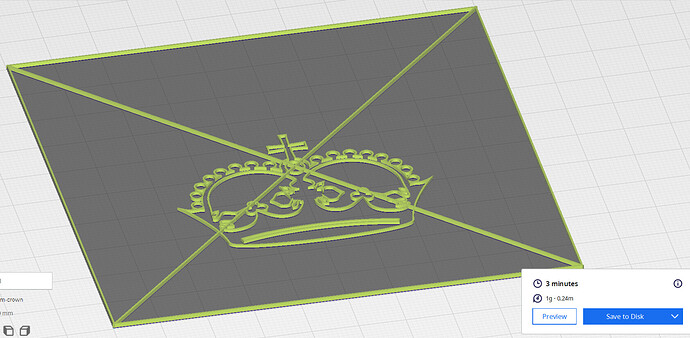

Currently printing bunch of 3min calibration crowns, nice fast try-tweak-repeat cycle time, tweaking various settings to try and dial in new Cura profile tuned for this printer. Am coming from a simpler Bowden Ender 3 Max. So, I get the opportunity to (re)learn settings for direct drive, linear advance, input shaping and bunch of other stuff that makes sense for this build. Will eventually share a Cura/Prusa slicer profile that works for me. Maybe someone has one already?

Update: Dimension lengths seem good, e.g. Crown’s outer border sides measured exactly 100mm. However, it’s skewed slightly, the diagonals were off (~140mm and ~142mm, should be 141.4mm). So, am following MP3DP v4 docs - Squaring and calibration, Klipper Docs - Skew Correction and other resources to fix…

That is a very flat bed and I love the cal crown.

Will eventually share a Cura/Prusa slicer profile that works for me. Maybe someone has one already?

I have a prusa profile, but I should look at it again. It isn’t my daily driver but I keep trying to switch. Trying to revamp things to use the ~50% nozzle/layer height ratio you pointed out, and keep my same flow rate so for a 0.5mm nozzle that means I chose 0.3mm @74mm/s instead of 0.37mm @60mm/s. Now I need to retune my accels.

Whole new test crown in the works, that is rad.

When I switched to my newest printer, I tried to just make the prusa mk3 profile work for my printer. They have some good presets and they move reasonably quick.

I’ve been trying to learn/use super slicer for mine. It seems to work well. But I have no idea if I have my profile set up truly correct or not lol

0.5mm nozzle that means I chose 0.3mm @74mm/s instead of 0.37mm @60mm/s

Any thoughts/opinions on using increments of 0.04 ? Google Search

Am blindly making sure everything, where possible, is divisble by 0.04. Widths, heights, distance, speed, acceleration, and nozzle widths even. No idea what’s the best practice, but pretty sure I’m over thinking it.

Our drivers are 256microsteps I don’t think that has any effect anymore, even when we used 16th stepping I never believed it.