I watched Teaching Tech’s video on this and it looks very interesting. Lets us know how it works for you!

Teethed idlers are need on the toothed side of the belt or you will see print artifacts of each bump. We use 6 Teethed idlers and 2 smooth ones for XY, On the Z axis we use 6 smooth ones.

(Z rail length + 100mm )*3

(Xrail + 100mm) *4

Yrail *4

That should give you plenty of extra.

5 pulleys

yes

yes

5 Steppers

Not optical, and we only use 2. The omron on teh store. work great as well as the red roller ones we used to use.

Now that I have LR3 CNC plasma and 48” magnabend, I can custom cut and bend sheet metal for enclosure walls and such! I’m eyeing this!

“Nuke it from orbit . It’s the only way to be sure."

(Ellen Ripley)

That would be amazing, it would be a true test of your precision with that bender.

I am making one out of HDPE right now.

ooops.

Sharp looking! How thick?

I have a small stockpile of 9.5mm stuff. I bought a stack of 10-12 cutoff quarter sheets at half price last year.

It machines so well I could not pass up the deal.

Our local Menards home improvement store stocks 4x8 1/4” HDPE in black and white! 1/2” available for ship to store orders.

Cheers! Thanks for clarifying/corrections. Updated my BOM post above. Better?

Yep, you’re right. I was mistakenly thinking about a Bowden setup.

Was expecting microswitches for Z Posts, but then I saw in Repeat V2 Topic, you mentioned “No z endstops is easy and works great.”. So, 2 is what I’ll get if I don’t have some already.

Looks great. Am all for use offcuts, planning to pickup some from my local acrylic/poly supplier.

You are the best! 3 spaces or bed springs, 4 if you are using one of those beds. Probably need to add a bltouch or other probe to the list. This is almost ready to cut and paste!

As I was making coffee this morning, it occurred to me that I could make a rudimentary calc by basing everything off of my 200^3 build and just making things like extrusions, belt, some screws (base measurement plus X amount per 25mm added).

I think I will try to dump some pictures on the page now with some warnings.

@vicious1 does extrusion dimensions exported from the model using script MP3DP v4 - Aza's build - #7 by azab2c help?

I added some resizing instructions. Only took a little over 2 hours. MP3DP v4 - V1 Engineering Documentation

Love the chopped off hand in the pics. Also, the face hiding behind the printer. ![]()

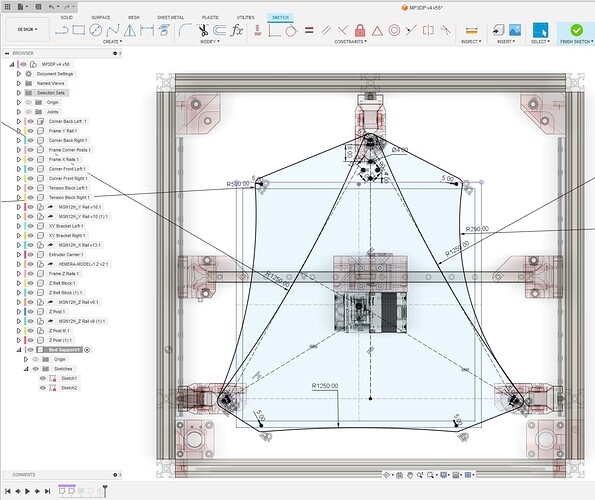

Question: Why isn’t this symmetrical? The light blue part for the four mounting holes and the print bed itself are not centered in the middle.

Because the Hemera extruder isn’t centered on the print head. It’s offset from the center, so the heated build platform should be offset from the printer mechanism by the same amount. It allows the X axis part to be as short as possible while giving access to the whole bed.

Edit: If you zoom in on the Hemera, you’ll see that the hot end nozzle is directly in line with the top center hole for the heated build plate mount.

Thanks, that makes sense. My symmetry loving brain needed to ask. ![]()

For folks looking to buy parts… Just noticed https://biqu.equipment have an Easter sale with prices that seem a bit better than the Sale they seemingly have for the few regular days we have between seasonal/festive related sales.

Anyone able to share BOM they have that covers parts beyond Specialty parts available at V1E Shop? Starting to cobble something together, using info from various topics, and VORON Design - Sourcing Guide even. Figured I should check with you guys first, before going to far, guessing several folks here have gone through this process already and have comprehensive lists, or spreadsheets even?

I have bought several items from AliExpress related to my hope for building a couple of these repeat V4 printers. These purchases have included bed heaters, solid-state relays to switch on the mains-powered bed heaters, and flex steel magnetic print beds as a package set that comes with the magnetic sheet. I’m trying to think if there’s anything else I’ve gotten from them. I am on the road right now, so I can’t provide you specific links at this time.

I have bought a couple of namebrand Meanwell power supplies. One of them was bought through marketplace, I think Walmart marketplace actually, but it was actually being shipped and sold from a company that carries Meanwell. The second one I bought straight from the same company but from their own website I think.

When I was building my Lowrider V3 plasma rig, I could not find the 24 V power supply that I had purchased for it (not name brand), so I wound up using one of the Meanwell power supplies that was intended for a repeat v4 printer. So if I want the two printers to match, I will need to swap in the power supply that was originally intended for the plasma rig. It is a thicker, fatter power supply than the Meanwell. Space is less of a concern inside that repurposed desktop PC tower, so that bigger power supply would fit better in there anyhow.

A lot depends on what you end up doing I know i severally under estimated the amount of screws a tnuts for my build. But honestly once Ryan says he is happy with the Panels I believe i will be switching to those. These printed corner brackets look great but there is just too much flex in it for me to be happy with it.

Yeah, am seeing ~115 bolts needed just for attaching the Front/Side/Bottom/Back panels, guessing M5x8 button head, assuming 1/8" thick acrylic panels? That’s before adding any corner/right-angle brackets.