Am trying to solve the MP3DP v4 BOM Puzzle. Using the clues in this topic and following info:

- MP3DP v4 Forum Topic | Fusion 360 model

- MP3DP v4 Pics of Ryan’s builds

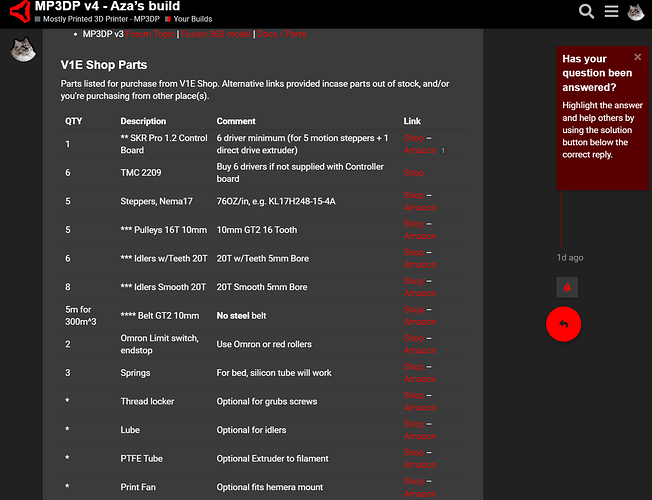

- V1E Shop 3D Printer Parts

- MP3DP v4 community builds have stumbled across.

- MP3DP v3 Topic | Fusion 360 model | Parts

Edit: Moved latest BOM am working against to my build thread. Hoping to delete from there too when MP3DP v4 docs contain BOM info.