I used M3x10, that needs at least 5.5mm thick panels. I think those give a tiny bit more wiggle room if needed, than an m5.

Some years back I bought a lifetime supply of M5 screws in various lengths. I mean a lot of screws. So I will probably use M5. I suppose I could save on how many of the nuts I would need if I were to drill into the aluminum extrusion, and then tap the holes. But I will probably buy a big supply of the nuts just to save myself some work, and preserve the ability to adjust as needed.

The magic of Tnuts is they can move. Drilling and tapping might make it too hard to adjust perfectly.

Check Sam’s/Costco’s kitchen section for hdpe cutting boards.

Current Work In Progress task for me…

Parts not listed on V1E Shop

Fasteners

| QTY | Description | Comment | Link |

|---|---|---|---|

| 62 | M3x8 | - Linear rails all use M3x8 - (x+100+(2 * (y+ 50) + 3 * (z + 50)) / 25 - Excel… =(A1+100+2*(B1+50)+3*(C1+50))/25 - e.g. 62 for 200mm^3 - One stepper mount marked with an “8” |

|

| 4 | M2.5x12 | 2 x 2 Endstops | |

| ??? | M3x10mm | ||

| ~113 | M3 or M5 Button head by 8+ mm | - 4 x 25 Side/Back/Bottom Panels - 13 Front lower Panel - (M5’s will have less wiggle room) - 8mm for 1/8" panels, 10mm for 5.5mm+ (e.g. 1/4") - Measure/check length needed for panel thickness |

Panel bolts |

| ??? | M5x30mm | ||

| ??? | M5 Slide in Nuts | - Use slide-in nuts, rotating T-Nuts are horrible | amzn |

Motion

| QTY | Description | Comment | Link |

|---|---|---|---|

| 1 | X Linear rail MGN | Usable X + 100mm MGN12H | Fila – Amazon (select correct dimensions) |

| 2 | Y Linear rails MGN | Usable Y + 50mm MGN12H | Fila – Amazon (select correct dimensions) |

| 3 | Z Linear rails MGN | Usable Z + ~50mm MGN12H | Fila – Amazon (select correct dimensions) |

Electronics

| QTY | Description | Comment | Link |

|---|---|---|---|

| 1 | Extruder or other tool | Hemera,example, match voltage, 24V is good. BIQU H2 or BIQU H2S REVO |

Fila – Amazon |

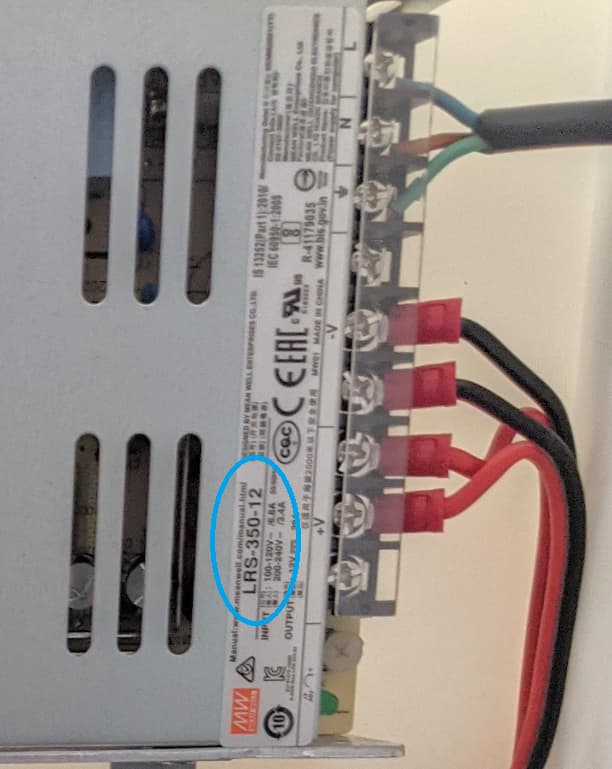

| 1 | Power Supply | Match voltage to your setup e.g. MEANWELL LRS-350-24 |

Fila – Amazon |

| 1 | Heated Bed | Style and Size will vary | Shop – Amazon |

| 1 | BL Touch Probe | ||

| 1 | Pi 4 or at least 3+ | Klipper/OctoPi controller | Good luck! |

| 1 | Micro SD | ||

| 1 | Display |

BuildPlate

- Alu?

Amzn – metalsupermarkets.com

Frame

-

For sizing info read this.

-

Consider Zyltech, Ryan(and others?) had bad experience with Amzn extrusion.

-

Corner Brackets Forum reco Jeffeb

Panels

- Material options

- 6mm /1/4" Plywood

- Acrylic/Polycarbonate

- ACM (aluminium-plastic-aluminium sandwich) great stable material, but $$$.

Cables

???

Vibration Management

???

Misc

???

Feedback/suggestions appreciated!

That’s my thinking (preserve adjustability)

Thanks for the info!!

Go to your local welding shop and buy a drop. I was able to get a 2 x 4 piece of 1/4" for $100 and milled my support and plate out of that. and have enough left to do another one if (who am i kidding…when) i build another one

ACM… check out piedmontplastics.com

They have some clearance stuff that is very reasonably priced.

Curious if there’s a voltage recommendation for power supply (for SKR1.2 or similar)? Guessing 24v but want to confirm.

Assumed everyone’s using 24V power supplies. But then I saw a Repeat with LRS-350-12.

Then I saw v3 docs specialty-parts has links for Power Supply, the filastruder link goes to 24V and the amzn link goes to a page with 12V (but other voltages/ampages can be selected too).

I put 24v on mine. Either will work. Just make sure you get the correct extruder for the voltage.

24V is better but all the parts I have around here are 12V so I am sticking with it for now.

Curious what material people are using for the triangle’sh Bed Support Plate.

1/4" painted MDF or Plywood? Using Alu seems overkill for something that doesn’t support anything in the middle, seems to be solid mainly to help retain bed heat? Also for 300 x 300mm Usable, would need Bed Support Plate larger than 12"x12", so larger $$ Alu stock would be needed.

I made mine from Aluminum because I didn’t know any better. I think 1/4" plywood or MDF would have been fine. But it does look cool knowing I cut it out on the LR3 lol

MDF, cheap easy stable

Nice, good to know. Will use 1/4" MDF, paint post cut, black looks great. Will help reduce material+labor. Agree with Jonathan though that Alu looks more Premium. Can always upgrade if am making something being showcased.

5mm plywood here, but I still need to do another one, since the one slot is in the wrong place.

For heat retention, I made a 1/2" foam piece that fits under the heated build plate. the extra insulation helps it heat up faster, and saves energy. I think it was a Teaching Tech article on using foam for a bed insulator that had some good numbers on the heating times and energy savings for using a good bed insulator. The wood just gets a bit warm underneath the heating plate, even at 100°C

![]() foam? Something special that won’t off-gas/ignite/burn? Do like the idea of insulating, have tons of mineral wool insulation (Formaldehyde Free) leftovers that will not set fire. But it frays too easily, spewing fibers into the air, would want to encapsulates and/or spray on some kind of fire retardant binder?

foam? Something special that won’t off-gas/ignite/burn? Do like the idea of insulating, have tons of mineral wool insulation (Formaldehyde Free) leftovers that will not set fire. But it frays too easily, spewing fibers into the air, would want to encapsulates and/or spray on some kind of fire retardant binder?

Appreciate the bed insulation advice, cheers!

Home Despot pink foam. Since the bed is never going to get to combustion temperatures, it will be fine. (Or if it does, I’ve got bigger problems!)