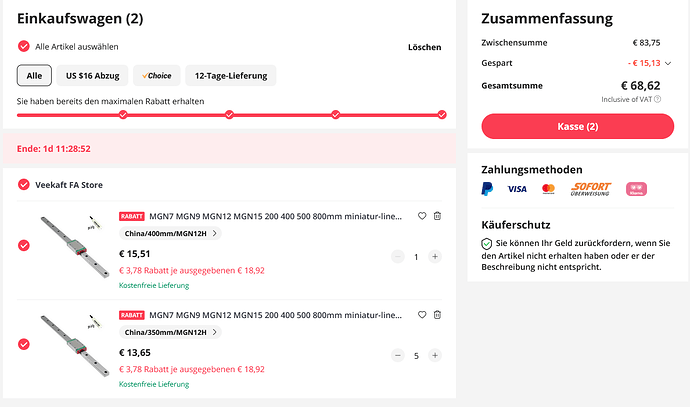

Is that a good price for linear rails for a 30x30x30 build? Just asking. ![]() I rrally would like to know…

I rrally would like to know… ![]() I don’t want to buy it, but the discount…

I don’t want to buy it, but the discount…

Currently digging around for Linear rails, have been using the links from MP3DP v3 BOM. Given how long ago the v3 links were shared, maybe there’s better price/value options to consider on amzn or elsewhere?

Motion

Related

- Ryan/ @ Barry99705 reco filastruder

- @ Barry99705 reco LDO Linear Rails

| QTY | Description | Comment | Link |

|---|---|---|---|

| 1 | X Linear rail MGN | Usable X + 100mm MGN12H | Fila – Amazon (select correct dimensions) |

| 2 | Y Linear rails MGN | Usable Y + 50mm MGN12H | Fila – Amazon (select correct dimensions) |

| 3 | Z Linear rails MGN | Usable Z + ~50mm MGN12H | Fila – Amazon (select correct dimensions) |

Have seen forum recommendations for LDO Linear Rails from https://www.filastruder.com

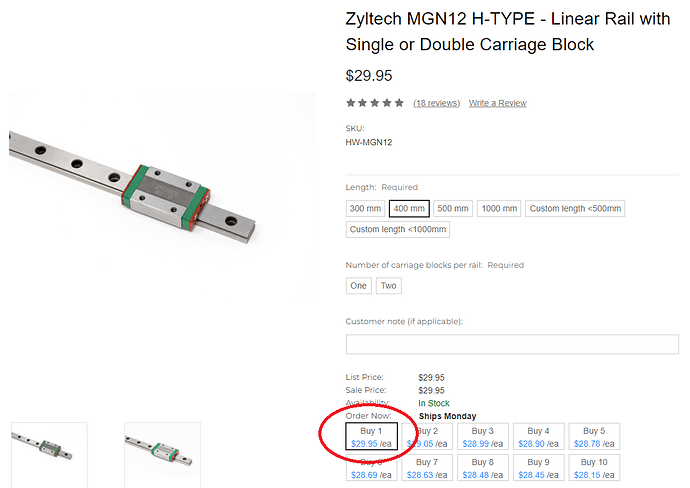

Am looking on Zyltech site too.

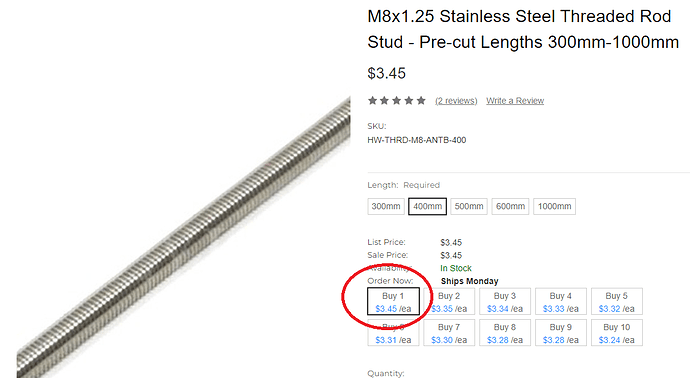

Honestly, I wept a little when I saw the price of Linear Rails compared to M8 threaded rod. Am wondering whether Z axis performs significantly better with Linear rails enough to rationalize the cost and Y axis space saving? I appreciate using rods would probably increase overall height since Z stepper would be fastened to rod at top or bottom (with thrust bearing?).

Differnt. The threaded rod would be replacing the belt, you still need some bearing surface to ride on.

There are V wheels and all the hardware they need (nearly the same as a liner rail). Or something like an Lm8uu or bigger. Those are a little cheaper but do not always last long.

I have some of these, $15, Amazon.com

and the longer one, Amazon.com, $16

50mm increments. Beautiful, no need to get the angle grinder out.

Taking close look at specs/reviews, may end up splashing out for LDO Linear Rail for X linear rail if they’re significantly more rigid. Building for 300mm^3, can always chop it down to be smaller if end result has insurmountable headache issues.

USER PARAMETERS:

- Usable_Depth = 300mm

- Usable_Height = 300mm

- Usable_Width = 300mm

Frame:

- 3x Frame X Back|Front 470mm

- 4x Frame Y Rail Top|Bottom Left|Right 445mm

- 4x Frame Z Front|Back Left|Right 445mm

- 3x Frame Z Mid Left|Right|Back 405mm

Linear Rails:

- 1 x MGN12 X Rail 400mm

- 2 x MGN12 Y Rail 350mm

- 3 x MGN12 Z Rail 350mm

2023-03-26 EDIT: Decided to not build 300mm^3, building diff dimensions instead…

I can’t imagine they would be significantly different in terms of rigidity, There is just a higher chance of getting a silky smooth one from the get go.

I’ll admit to looking at the POM wheels that ride on V slot as an.alternative to the MGN12H rails for Z, it’s pretty close to the trade-off point for 250mm usable (300mm rails) to get a 4 wheel carriage piece to ride the extrusion, then a relatively simple adaptation to bolt the Z motor carriage to that. This actually starts to look pretty good for super tall builds, when the cost of the MGN12 rails starts to go up faster.

Going back to a panel frame, I can imagine going with 8 or 10mm smooth rod with LM8UU or LM10UU linear bearings. A single rod is probably good enough, but a double is a better bet to make sure the Z axis can’t rotate in ways we’d rather that it not. That gets picky about keeping them mounted parallel, but for a single part, that’s easy enough, and zip tie the bearings in leaves enough wiggle room for printer tolerances.

It’s all intelectual excercise, at this point. I may even draw up parts, given that I have rods and linear bearings lying around with no other purpose. Maybe I’ll use them for a marble run machine, to tilt a marble maze.

BOM list/status…

PARTS - Decisions and purchases

HAVE / BOUGHT:

Probe : Have unused BL Touch

Frame: Have Black/Silver extrusion leftovers

Wifi: Have Pi (will Klipper/OctoPi)

Controller: Octopus v1.1

Drivers: 5+ TMC2209 (EBB 36 has TMC2209 onboard that can drive Nema 14 in BIQU H2S V2 REVO)

Display: Bigtreetech TFT E3 V3.0.1

Linear motion: Iverntech, chose because deliver fastest and best seller… Wasn’t reco’d by forum, so could be mistake, will find out…

NEED TO BUY:

Extruder: BIQU H2S V2 REVO - Paying premium for REVO to reduce effort for kids/me to change nozzle.

Nozzle: REVO 0.6mm (for now)

CAN Bus controller: EBB 36

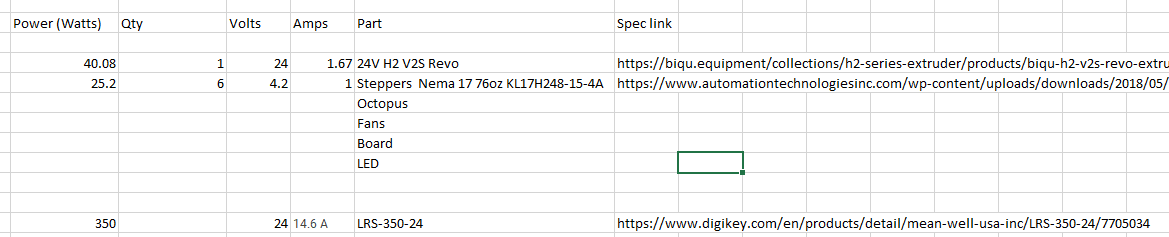

Power Supply: MEAN WELL LRS-350-24, enough/too-many Watts?

NEED TO DECIDE:

Heater Bed:

Fasteners: Need to rummage thru existing piles and figure out what’s required.

Wiring: Same as above.

Depends mainly on heated bed.

Most DC heated beds are well within the range for that power supply, but some can exceed it in the larger sizes. If you go with a mains powered heater and an SSR, then your PSU is heavy overkill, as the next heavy load is the hotend, typically around 50W. The rest of the printer is maybe that much if you’re being generous with budget. Still, overkill at least is less prone to failure, or at least it seems that way.

Cheers Dan! Have been holding off from ordering PSU until I decide on Bed Heater. About to re-read through all the MP3DP topics to help figure out. On the fence about using mains powered heaters with SSR (Solid State Relay switch), I need to read up more on safe guards and risks, am not the only one using the printer (that’s the dream…).

Started trying to piece together watts/power used by components instead of blindly picking an oversized supply. Guessing someone’s done this already?

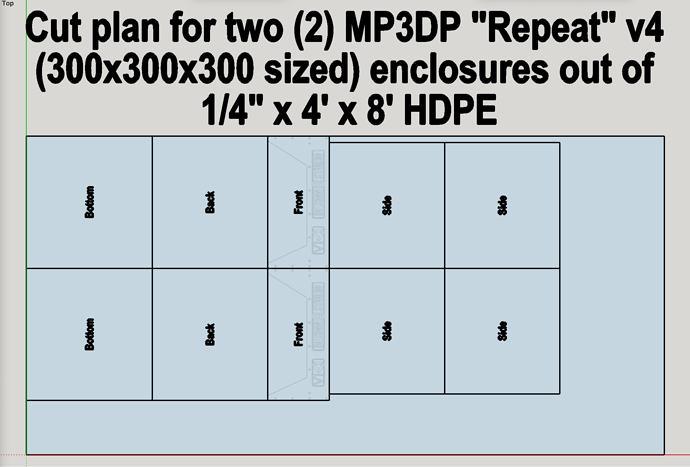

Someone had pointed out that Menards stores stock and sell 1/4" HDPE full 4’x8’ sheets, for about $88 (current price) and that’s before you consider their 11% mail-in rebate.

I’ve been aiming to make two of the Repeat v4s, at 300x300x300 usable area. In case it helps anyone, here is what that would look like as a cut plan on a full sheet, regarding the enclosures for two:

Interesting. Have a TAP Plastics store near me, they have a great selection of materials. They have a cutting service, so you only pay for what you’re using (no need to buy a full size panel). But the cost per square foot works out $$$.

Fortunately, they have a scraps section where most material is $1 per square foot, but the scraps are mostly 1sqft, useful for small projects. Even better, they’re closed on the weekends, so am hoping to get an even better deal by going dumpster diving later today.

Anyone in PNW/Seattle area able to recommend reasonable priced plastic supplier? No Menards in our area.

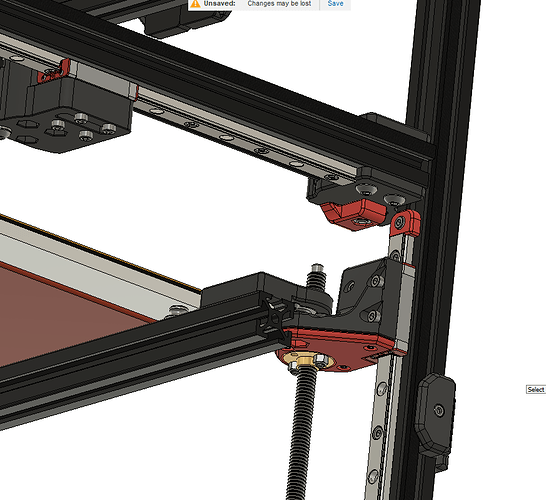

Doug, with panels being 1/4" thick, are you thinking of not using extrusion, and instead just rely on the HDPE to be the frame/box, like a Plywood construction Repeat v1? Or is 1/4" thick HDPE not thick enough to directly support the rails/hardware?

No, I am planning on 2020 extrusion frame, with the panels added for all the benefits that brings, rigidity, helping with squareness, protection from drafts, etc.

I’m glad we have a Menards within driving distance, but they are working to get one built right in our area. Cannot get done fast enough as far as I am concerned. The average project I do, always costs less to source materials from Menards over Home Dept and Lowe’s, and that is before the 11% mail-in rebate is considered.

Voron Trident: Why choose between Linear Rails or threaded rods, when you can spend more and use both.

Me: Looks cool, but not something MacGyver would come up with.

Hey, can you help me know what a “drop” is? Are you speaking of aluminum or steel? I am curious!!!

This seems kind of important. LOL ![]()

I’m certainly no engineer. I think the one (rail) is guidance/bearing surface, while the other (threaded rod/lead screw) is propulsion. In this regard, for the Repeat V4, I think the analogy is rail for guidance/bearing surface, with belt for propulsion. ??

It may not be a correct term but we always call a “drop” material left over. So a welding shop gets a full sheet of steel aluminum whatever for a project. Cuts what they need off of it. Im sure charges the customer for the full sheet. Then sells the “drop” at a reduced price. The welding shop near me cut the price of that aluminum just about in half of what it would have been from the new supplier where i would have had to get a full 4x8 sheet at $800+

@Jonathjon

Thanks!!