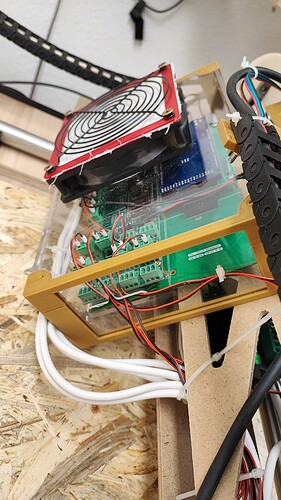

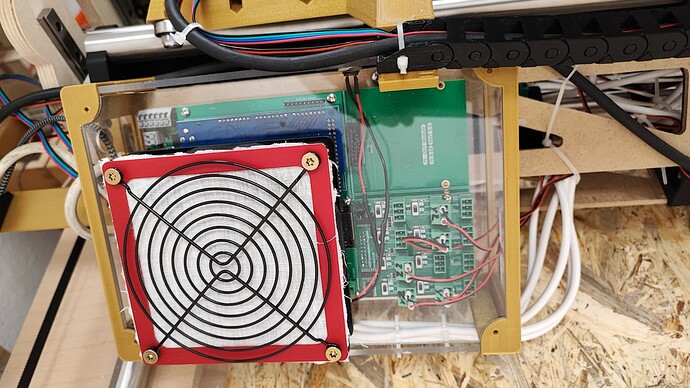

Box done, the red on the fan being the last remnant of Schneewittchen:

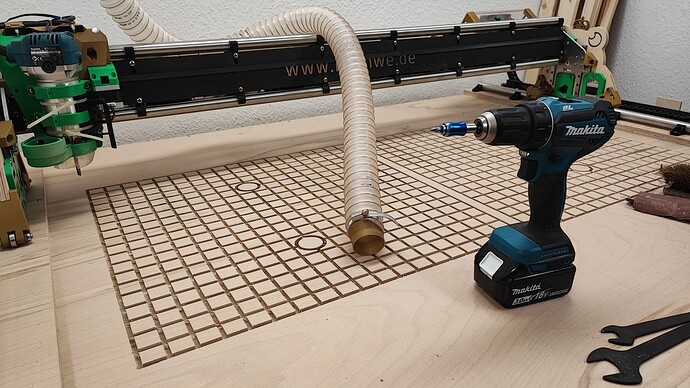

I think you’ll know where to look if you start missing wrenches (spanners for our folks across the pond)!

![]()

I like the table, the color scheme and the controlbox.

What was your biggest hurdle on this build?

Time… ![]() Too many kids.

Too many kids.

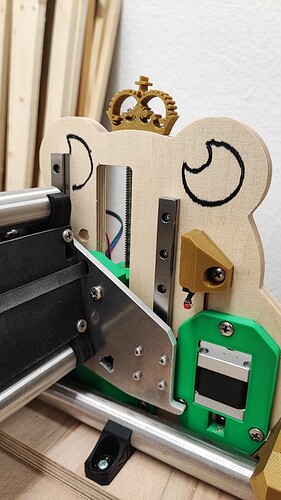

And my stupidity when trying to install the X-belt… ![]()

What Makita router is that? And are you satisfied with it?

Makita RT0700C, the one that everyone has. ![]()

I can find the RT0700C here but there is also RT0702C.

Will that one work as well?

It seems to be a newer version with an LED indicator and a protection against turning on again after the plug having been pulled when still in the “ON” setting. At least that’s what google says.

Testing some acryllic cuts myself now.

Hopefully I’ll be able to make my YZ plates out of 12mm pieces.

Do you mind sharing your trochoidal settings?

I tried a single flute upcut, almost lowest speed on router, 12mm/s feed rate, 2mm Depth of Cut, 60 deg plunge angle, 2mm/s plunge rate.

My first cut (not trochoidal) lasted about a second ![]() :

:

I used a single flute upcut bit with nearly the lowest speed on the router, 1500mm/min (so 25mm/sec), 4.2mm DOC, straight plunge (when doing trochoidal it goes down in circles anyway), 450mm/min plunge (7.5mm/sec) and 20% trochoidal stepover.

It’s really important to go quite fast to have big chips or it will melt. Christian, the guy who made Estlcam says you should go as fast as you can without your router losing its way (because of the forces when going in circles) and also advises to cut the full depth. In your case I’d go 6.2mm DOC, same settings for the rest that I used. Using a 6mm endmill, I cut aluminium at nearly the same speed with less stepover and 10mm DOC (with a bit of flex, to be honest, but it did work well).

Thanks!

I’m going to try your settings.

Just did a crazy test here with some very poor choices:

Did you do a finishing pass?

That did not seem like it was trochoidal so may not be a good idea

Nah, I never do finishing passes. I have never had the need, I use those diamond endmills for plywood that leave a great finish, for hardwood I have also never felt the need to do that. Look at how good my pencil cases look. ![]()

It depends on the final accuracy you need. Professionals using machines far more rigid than we have use finishing passes for machine work, when they are looking for 3 decimal place accuracy. For most woodworking, we can probably get away without, depending on how much we are pushing the machine. Going slow to start, we may not need it, but if you are pushing the machine, you probably are getting some deflection of the tool, in which case a finish pass will leave a more accurate dimension.

I don’t use finishing passes for things like screw holes, but usually do for things where edge finish and accuracy are desired.

I re-read some (not all) of your build thread and I was wondering about your workflow.

Perhaps you could post more videos? And do you use the laptop and the laptop wallstand often?

You can check my Youtube channel: HaWiWe.de. You will find a few videos with the workflow. ![]()

Since I use Estlcam as PP as well, I need it all the time. ![]()

and now, today is going to be a great day!

Also: vacuum table coming along nicely. Took 24 minutes with 3000mm/min and 6mm DOC (which made the side lift off the rail a bit. Whoops…).

That is a bit fast, guessing that caused it. I did a 8mm Deep 12mm wide cut in walnut that was wild, I don’t think mine lifted. Do you happen to be using a downcut bit? Was it a fast plunge or while slotting?

I don’t think I have heard of a lift yet, Kinda want to make sure that is not a common issue.