A set of calibration tests sounds helpful. You thinking along the lines of a CNC equivalent of Teaching Tech’s 3D Printer calibration website? Has been mentioned a few times…

I appreciate how the build docs walk people through to creating the Crown of success. This was really helpful when getting started, as are the additional milling guides throughout the docs.

For me, going beyond that involved fumbling around in the dark, and this forum. Would be nice to easily assess the health/performance of a machine relative to what’s expected (maybe the community average?). I appreciate this is tricky, especially when people use different sizes and materials.

Have been Rapid Speed testing (with no drill bit attached) to non destructive failure, this helped me identify things to fix/tweak, e.g. vac hose should be strain relief supported, and leadscrews/emt benefit from lube.

Have been making a note of settings that are working for others’ machines, am using this info as a guide, am not expecting to match performance of smaller more rigid better built machines. This info has been more helpful than not. Pasted current snapshot of actual observed settings below…

| Quality | Material | Bit | DOC | Plunge Angle | Feed XY | Feed Z | Speed | Coolant | Notes / Source |

|---|---|---|---|---|---|---|---|---|---|

| Acrylic | 3mm 1 flute upcut | 6mm | 60deg | 20mm/s, finish: 10mm/s | 2mm/s | Makita/Katsu 1 = lowest | None |

@Olivier Acylic on LR2 - step-over: 30%, trochoidal-stepover : 20%, trochoidal-width: 50%, oscillation: 0.05mm |

|

| Polycarbonate | 1/8" 2 flute straight cut | 3mm | 45deg | 50mm/s | 13mm/s | ??? |

@jjwharris - Video @ video 847c03f6 0654 4d28 b0d0 84ceae98fddb 1663980592 - YouTube - Cutting Polycarbonate - #7 by jjwharris |

||

| Great | Cast Acyrlic | Carbide 1 flute upcut 3mm Wirbel 1 Schneider? |

5.5mm | 60deg | Troch 25mm/s | Troch 7.5mm/s | 10K (Makita Lowest setting) | NA | @ Tokoloshe step-over:75%,trochoidal-stepover:20%,trochoidal-width:50%, oscillation:0mm , - Video @ Control Box for the Open CNC Shield 2 - Der Froschkönig - Lowrider 3 in Oldenburg, Germany - #91 by Tokoloshe - First Acrylic cut - Advice please - #26 by Tokoloshe |

| ? | Alu | Carbide 1 flute upcut 6mm | 10mm | 60deg | Troch 25mm/s | Troch 7.5mm/s | 10K (Makita Lowest setting) | NA | @ Tokoloshe step-over:???%,trochoidal-stepover:???%,trochoidal-width:50%, oscillation:0mm, - Der Froschkönig - Lowrider 3 in Oldenburg, Germany - #91 by Tokoloshe |

| ? | Cast Acrylic | Carbide 2 flute upcut 1/8" | 2mm | 90deg | Troch 8mm/s | Troch 1.6mm/s | 7K | NA | @ barry99705 step-over:30%, trochoidal-step:20%, trochoidal-width:50%,oscillation: 0.05mm ? - MPCNC Trochoidal cutting - YouTube - Acrylic Troubleshooting - #21 by barry99705 |

| ? | Cast Acrylic | Carbide single flute 1/8"? | 0.5mm | 90deg | 18mm/s | ? | 8.5K | ? | Bits for cutting ABS/PC plastic at 1/8 inch thickness - #5 by robertbu |

| Great | Cast Acrylic | Carbide single flute 2mm | 0.4mm | 90deg | 10mm/s | 3mm/s | 5k | NA | First Acrylic cut - Advice please - #9 by Kavster |

| Meh | Alu | Carbide 1/8" | 0.25mm | 90deg | 3mm/ms | 10K | WD-40 | Aluminum plates for LR3 speeds and feeds - #6 by azab2c | |

| MDF | 1/8" | ? | 90deg | 50mm/s | LowRider maximum speeds and feeds? Depends, cut deep with slow feeds to max cut volume - #3 by barry99705 | ||||

| MDF/Particle | 1/8" | 13mm | 90deg | 14mm/s | 4mm/s | 20k | NA | Topic includes Ryan’s profiles Doing some more speed testing - #4 by azab2c | |

| MDF | 1/8" | 12.5mm | 90deg | 22mm/s | 7k | NA | LR3 Speed - #4 by azab2c | ||

| Soft Wood | 1/4" | 10mm | 15mm/s | 10mm | NA | LowRider maximum speeds and feeds? Depends, cut deep with slow feeds to max cut volume - #12 by barry99705 |

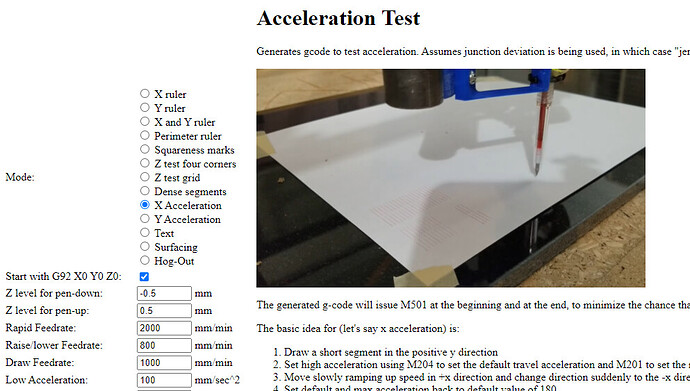

Jamie has some tests within his Test Pattern Generator…

Ideally, we’d get to a state where people would be able to Opt-in to sharing anonymized metrics about settings that are working for their build configuration (via EstlCam and/or most commonly used toolpath generating app?). The machine setting data could help detect good/bad outlier behavior that could be actioned in multiple ways. i.e. Auto help struggling individuals (via ChatGPT which can do any and everything ![]() ), and, also identify and spread best practices/mods to level up the overall community.

), and, also identify and spread best practices/mods to level up the overall community.

e.g. Phillip went through all sorts of hell troubleshooting quality issues that ended up largely being a result of worn out bit. “There’s got to be a better way…” - Shark Tank

I still think the Coasty CNC speed test would be great. Different levels of difficulty, e.g. Cuts, Carve, Inlays, etc… Something with utility value that advertises V1E and can be given to friends, and/or strategically ‘accidentally forgotten’ in various hardware stores around the world.