What DOC/feed/speed settings do you/others use for Plywood/Softwood?

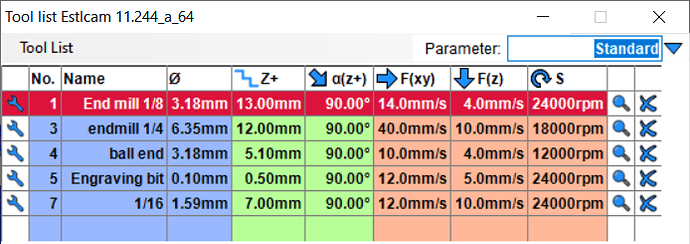

@vicious1, cheers for sharing the zip containing your estlcam settings (for just MDF/Particleboard?). You’ve given me performance numbers to strive for, knowing what’s possible is very helpful.

Previously read/learned from you and others recommending to do slow deep cuts in other forum topics. However, I didn’t realize, for your specific machine build, just how deep your depth of cut is per pass using 1/8" bit on MDF.

Have been using feebly shallow 1mm per the docs @ Milling Basics - V1 Engineering Documentation, which understandably needs to pick numbers that will work for most people’s builds and stock material.

Appreciate depth of cut and other settings will vary depending on people’s builds, materials used, assembly quality/variances, etc… Something that, to maximize performance and acceptable quality, needs to be explored and calibrated using some tests/tuning following some step by step process. Guessing there’s a CNC equivalent to Teaching Tech’s 3D printer calibration site somewhere?