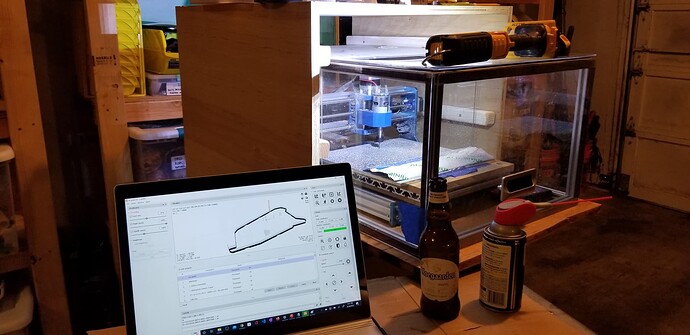

Appreciate this thread, this is my first time cutting Aluminum…

Anyone able to share/brag what awesome feed, speed, depth of cut, plunge rate, other settings helped them successfully cut LR3 XZ Plates using their existing 3018 or similar CNC? Currently waiting for 2nd plate to wrap up on my Genmitsu 3018 Pro Ver with 3040 extension. 4th 2 flute carbide 1/8" in 3hrs… Creating some great thermite grade aluminium dust at 200mm/m, 10k RPM, 0.25mm depth of cut, drowning with WD40 every 0.5mm.

Was too impatient to wait for amzn to deliver 1/4" or 3/16" single flute short cut (i.e. 1/2" cut length, 1-1/2" to 2" overall length) carbide with titanium something coating. Had enough time waiting for this job to finish that I’ve learned to love watching YouTube videos of large Alu shavings fly off into a vac hose.