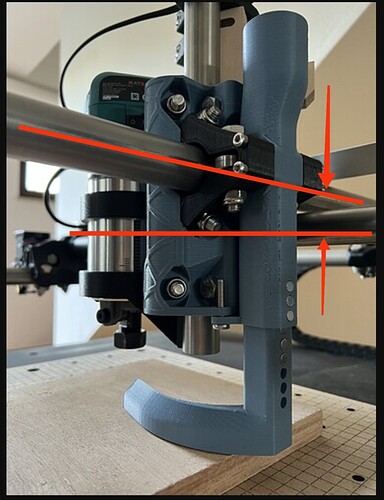

Hi, I was thinking about making something a bit different, and I would apriciate if anyone could give me advice on this. Basically gantry is held and moved by 2 round tubes that are few milimeters apart. What would happen if they get bigger height difference? Basically making them 40-50mm apart, would that increase rigidity of Z axis during cutting? If we ignore 3d print plastic flexing, wouldn’t that type of design offer much much better stiffnes when cutting? Or would it make it somehow much worse?

I am not sure, what I am sure of is that your dust shoe is awesome. ![]()

The difference is the amount of offset from the gantry tube that the other tube is held. So rotation is limited by the distance from the tube to the far holder for the other tube.

Distance betwen the tubes vertically is a double-edged sword. Greater distance means sin theta greater distance as measured above but means more printed plastic, not steel in the geometry. Shorter is stiffer there.

Take a 12" long piece of 1" steel tube and try to bend it in your hands. Yeah, I can’t either, but a 10’ piece is reasonably easy to get a clearly visible bend in. A few mm of plastic might be hard to bend where a dozen cm might not be as difficult.

Flexing of the core is the weak point on the Primo, if everything is kept short. For mine, the core has enough strength that the long Y rail will bend instead (37" cutting length) so it’s more than enough for that.

Yes OP please tell us more. I love this sickle shape, I imagine that was designed to match the cast pattern of the dust/chips? Does it work better with different milling techniques ie. climb cuts?

Regarding the rigidity, I would assume that moving either rail further from where the forces are produced (where mill meets material) creates a larger lever and thereby reduces rigidity? Not sure if that’s just a restatement of what Dan said.

Which begs the question - if it weren’t impractical for what I assume are numerous design and clearance reasons, would reversing the trucks (so they cling to the bottom of the side rails rather than ride on top) theoretically improve rigidity?

Sorry about dust shoe, but picture is not mine, I found one online that had best view angle to demonstrate my idea

I was thinking about some aluminium gantry mod, probably lost PLA casting or aluminium angle for gantry with 25mm linear bearings. I’m amazed by MPCNC design, and I would like to keep same principal while adding some ridgidity. I was thinking about moving one tube higher, because with bigger Z axis it makes more leverage when cutting, and to cancel it out increasing height difference would help in my opinion. Did I miss out on something?

I image searched and found original post about that dust shoe design, here is link. It is not mine.

@DJPicasso made a stability mod a while back, chasing zeroes. Turned out well:

and here ![]()

and also here ![]()

Thanks, didn’t find those. ![]()