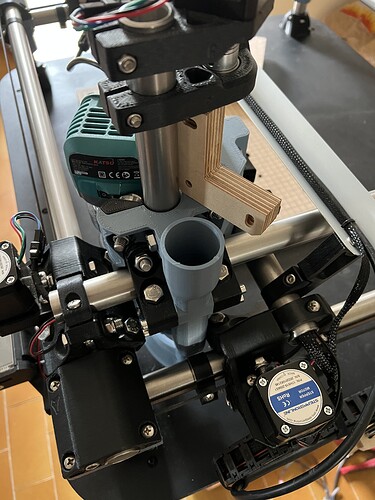

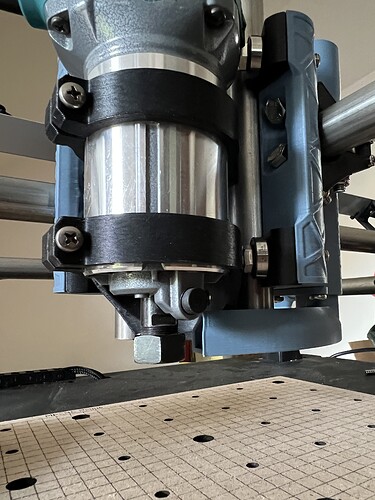

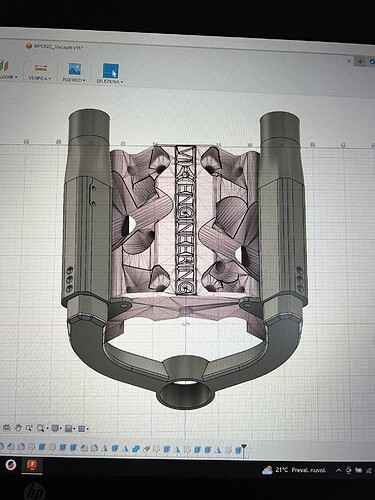

Hi, I’m working on a vacuum system that fit inside the available space, without reducing the machine movements.

THIS IS NOT WORKING YET, it’s only a mokeup for verify the fitting, it’s too small and the idea is to double it up symmetrically, for increase the total duct section.

Magnetic system is actually too weak to withstand the vacuum force.

I will post here the following updates.

There is a great one already where you only lose 5mm. You can find it here: Printables. I used it on my Primo.

Beside that the idea looks really neat as well.

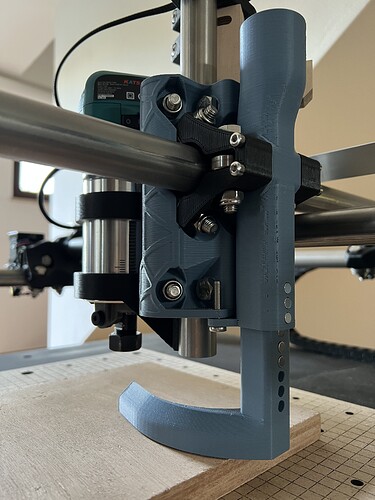

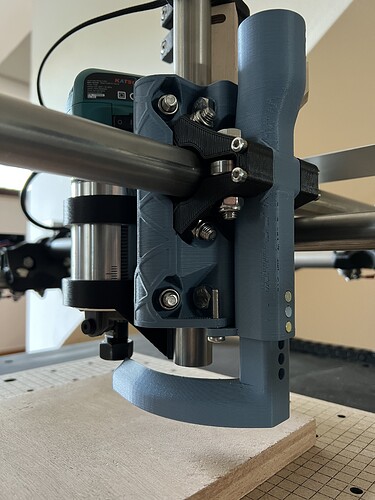

It’s really nice🤩, but the difference is that my design do not add any force on the router, and it seats next to the workpiece surface all the time. Even when the router goes all the way up.

Very nice design. I’d been trying to figure out a way to use those same mounts for a dust collection. My solutions were not that elegant. Can’t wait to find out if it works out. My table was covered with so many maple chips today that I REALLY want a decent system. Keep me in mind if you need a beta tester. ![]()

-Ryan J.

I know what You mean😂

In the next few days I’ll try it, if it works I’ll share it😉

Usually I use Solidworks, but this time I’m trying Fusion360, and the different workflow and interface are getting me slow…![]() I’m thinking to get the dimensions i found and redesign it from scratch… I’m way more confident with SW.

I’m thinking to get the dimensions i found and redesign it from scratch… I’m way more confident with SW.

Any progress on this? The system I’m currently using has some serious limitations. I would love to give this a try.

I made a very similar design:

maybe useful ideas there?

Holy Schnikes!

Did this dust work?! Did adjust for z changes the way it looks like it should in the picture?

Next big question:

Would you consider sharing this model??

Never tested in real life, I don’t use the MPCNC anymore, the LR is way better for my needs.

the model is already on Printables (MPCNC Primo 25mm Vacuum System (Prototype) by Rico_LRS | Download free STL model | Printables.com)