Oh yeah my minimum layer time is 5s, so whenever I make these speed tests - it’s getting up to speed only on wider layers

That’s important. You probably can’t change that after you build it ![]()

ohhhh…300 x 300 x 300 enclosed to print ASA… That’s what I want…

Take good notes ![]()

Am I the only dummy that prints ASA on an open printer with no problem at all???

" According to MatterHackers, Simplify3D, and 3D Insider an enclosure is not necessary but highly recommended as ASA, like ABS, is susceptible to drafts and can warp. A heated bed is necessary (somewhere between 90-110 °C), and little-to-no cooling fan used. The enclosure helps ensure adhesion and a consistent temperature. ASA also has fumes and an enclosure can help contain unwanted smells."

I just want mine enclosed…and a direct drive.

I’ve been stuck with a stock Ender 3 Pro for so long, I want to make sure whatever I have next is flexible. Big enough for whatever I need. Can be enclosed, or not if necessary. Direct Drive so I can print TPU, etc.

I don’t even attempt to venture into anything except PLA with this one. PETG a few times, that’s it.

Same reasons I built the 300x300x"400" v4

I havent tried to print any ASA with the V4 yet. But i have printed some TPU and it went surprisngly well. Needed a lot more tuning but i got what i needed and was happy. So far the only thing i have printed ASA was the spindle mount for one of my LR3s and the core for my V4 that got burned up by the heater cartridge backing out of the block. Both of those were printed on my very open CR10S Pro lol. I do want to try and print another ASA spindle mount for my second LR3 so I may give it a go when i get back home and see how it works out.

Jonathan, I thought in Florida your “shop” was a “heated enclosure”, for a better part of the year. ![]()

BIQU H2 REVO Part Cooling Fan Duct observations/improvements

Part Cooling Fan Duct shared in earlier post is better than nothing, and helped print LR3 Cores. However…

Seems like improvements are needed for the Part Cooling Duct to be useful at higher speeds:

- Duct holes are too far apart, and too far forward from the nozzle.

- Duct openings are probably too small (3mm x 14m) when compared to other printers, e.g. Voron Trident (3mm x 23mm) duct openings.

- Should enlarge volume of duct channels routing air from Fan to Vents.

- Interface to radial fan should be external instead of internal to maximize air volume.

- Geometrically simpler, less sweeping curved parametric lower ducting would be nice to create, and tune/refine. While ensuring ducts still clear the BLTouch mount.

- Currently using a 24V WINSINN 5015 Blower, spec says 3.23cfm. Ordered similar dimension blower with 6+ cfm, we’ll see… Noticed some people using 2 blowers, or larger 70mm blower, or CPAP tube being fed air from frame attached blowers. Hoping a stronger 5015 will be good enough so part cooling isn’t the bottleneck.

- Other stuff?

Don’t have time or fluid simulation software to investigate and improve at the moment. Sharing some observations incase someone’s interested in pushing this further…

Lol! Problem is you can’t print anything outside where I’m at. Humidity at 80-90% doesn’t fair well with filament lol. I have a food dehydrator that I use to dry the filament and then put in rubber made food boxes trying to keep the humidity down lol

If I would go back I would choose a 300x300x200 - I would expect less vibration since extruder is moving on the top of the printer. Alternatively, maybe, mount the printer from the top, like a kitchen microwave

That is an interesting idea… mount from the top… the rails are long enough I could slide them up and do just that, but they should mount to something very flat and very solid like - - - the under side of a cnc torsion box? That might be interesting, but kind of a pain to access.

That’s what I built…

Noted. I know I’ve read through your thread, but I haven’t really looked that closely at most of the printer threads because I’m not at the point to actually build it, but I will definitely look closer at yours as well when the time comes.

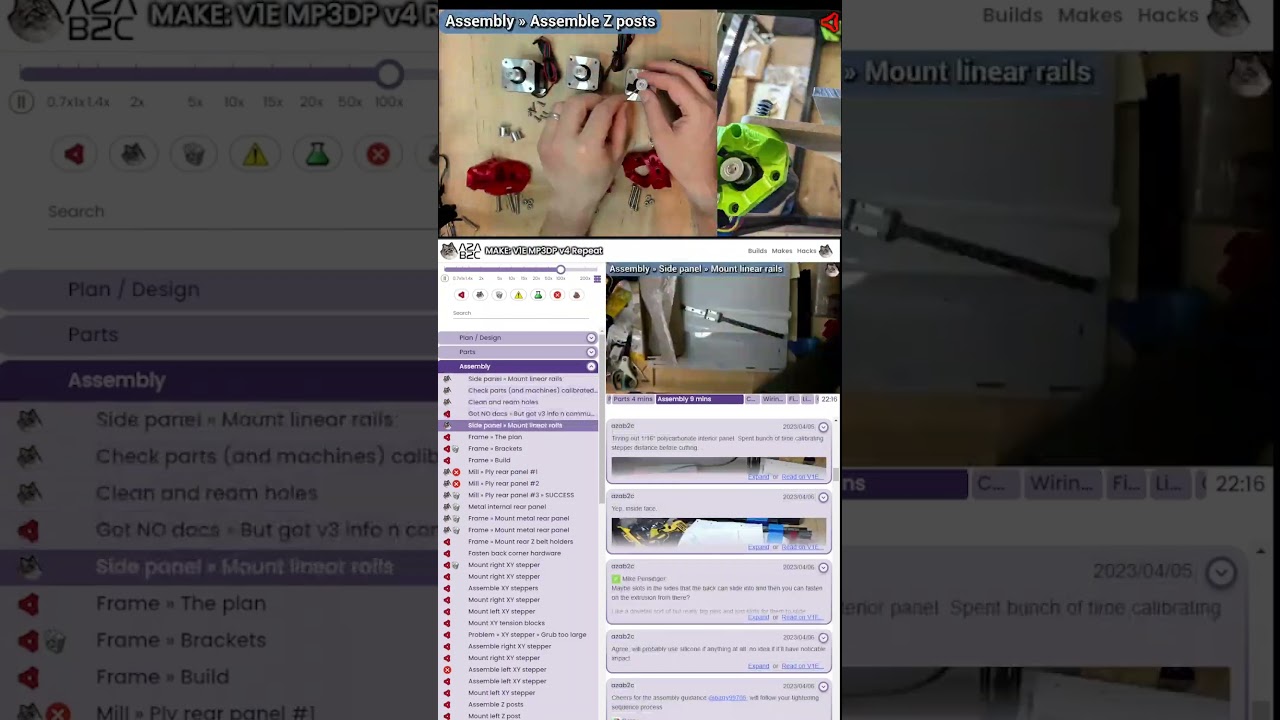

Does MP3DP v4 Repeat 2 have a logo?

Am wanting to slap V1E + Repeat logo all over this short…

Edit: Removed link to draft video.

Nothing besides the standard three lobed 120 logo.

Thanks for confirming Ryan. Published this version…

Best viewed within YouTube app, at 1080P 60fps, while highly caffeinated. Labelled as “MP3DP Repeat v4” which isn’t accurate, but makes sense to me. Will share longer form version when ready.

Hey @vicious1, got a preference for how MP3DP should be # tagged in tweets? e.g. #V1E #MP3DP, or #V1E3DP, or #MP3DP or something else?

Those look good. I will “watch them”, and update my BIO’s Thanks!!