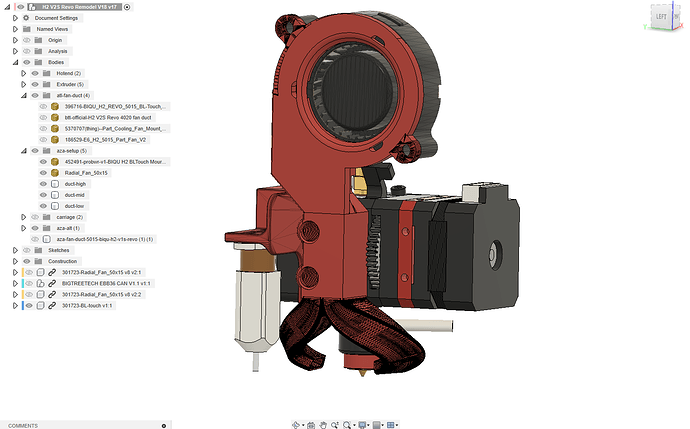

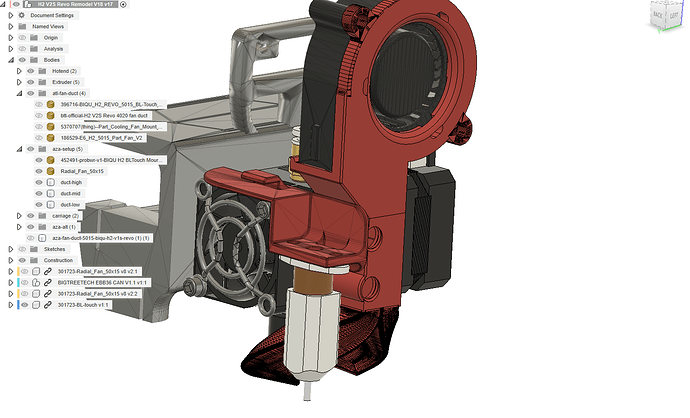

BIQU H2 REVO Part Cooling Fan Duct

After digging around, finally got around to adding a fan duct, with M8 grub screws to seal holes the M3 bolts are fed through…

Shared on Printables…

Designed the duct to work with and clear @probrwr’s BLTouch mount. I still need to upgrade to Mike’s latest rail mount.

Heavily based on 396716-biqu-h2-revo-part-cooler-5015-bl-touch-mount, but also steals ideas from several other models I reference on printables.

Created this after not finding what I wanted :

- Must allow full motion of tensioner arm, which should be comfortable to access.

- Must enable dissassembly for dealing with filament jam/clogs.

- Must leave extruder stepper clear as possible for heatsink(s).

- Must leave front right holes clear for mounting stuff.

- Must be clear at the front so nozzle can be clearly observed.

- Must ensure Fan Duct placement is compact and not sticking out too far forward. I have limited front room due to my MP3DP’s polycarbonate lid.

- Max air flow. Partial success here, I widened the opening, but could have done more to max flow.

- Nice to have clip holes for custom grill to mount…

Parts

Printed 0.6mm nozzle, 0.32mm layer height. 0.2mm layer height would be better, especially for the grub screw threads.

- 2x M3x25mm bolts and nuts

- 2x M8x4mm grub screws/bolts (or shortest you can find, am using M8x8mm from my parts stash).

Klipper firmware config

Updated klipper/printer.cfg with…

[fan]

pin: EBBCan: PA1 # FAN2