Here is my prusa slicer profile…I think. Unzip and import.

PrusaSlicer_config_bundle.zip (3.8 KB)

Here is my prusa slicer profile…I think. Unzip and import.

PrusaSlicer_config_bundle.zip (3.8 KB)

Awesome, thanks a lot! I will try this slicer profile out on my machine and check my results. Will report back.

I used @vicious1 Repeat V4 0.5 nozzle slicer settings and it worked perfectly for the Benchy.

Thanks again Ryan!

I will probably go back through the tuning tests at some point to see how I am doing with the 0.5 nozzle and everything. But right now I have a backlog of prints that I have been waiting to do so I should knock those out first.

Well, it looks good, there is some ringing. So accels are a bit off, maybe too fast. Hard to say. Mine are starting to show some ringing so I wonder if I have been creeping up the max speed. So when I get caught up with prints as well I will do some tuning see if we meet in the middle.

I did notice the ringing. That one I can live with for awhile until I get time to tune it. Overall, I am just happy to have clean parts while also reducing my print time compared to the 0.4 nozzle.

You guys need some input shaping.

Well Marlin input shaping doesn’t work on CoreXY, so is there any other option then klipper?

don’t think so.

Hmmmmm, lemme think about it.

“Should” be a pretty easy conversion. Mp3dp doesn’t have many fancy options.

I don’t think I have ever showed my camera setup. Here is a camera arm I drew up to travel with the bed. Also has a light bar. Simple, gets the job done.

It looks so nice!

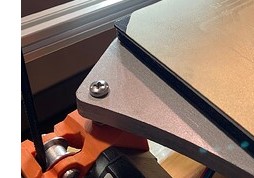

This assembly is reverse. The bed plate needs to be on the hard surface or the spring will flex as you add material. Spring goes on top.

Also it seems you are missing the slot in the bed support. Does your bed have much freedom of movement?

Oh interesting. I am not sure how I never noticed this before. I have never had issues with the bed movement/flexibility. It has plenty of movement per axis when keeping the other axes still. Seems fine. But I will switch it around and see if it gives it more movement.

I realized after I cut the plate that I did a hole instead of the slot, but I went with it anyway and it works perfectly fine. Realistically, the bed should never distort itself more than a few millimeters. When it rests on the bottom of the machine in the “off” position it should be pretty flat and then when you G34 it shouldn’t have much adjustment. So I have never come across a situation where the flexibility has hurt me.

No slots is fine, they are there for future non planer, if it happens. But the springs need to be on top for sure. Your print quality should go up a smidge, in the Z axis I would imagine…

Non planer would be awesome…

I will switch the springs around the next chance I get. I am going to do an acceleration test before and after switching the springs positions. Wouldn’t you think the ringing affects would decrease? I would think the bed being less bouncy would help with that. When it makes a rapid movement/acceleration I am sure the bed rocks a bit on the springs.

I doubt you would notice it close to the bed, I assume it amplifies as it gets further. With no slots though, you are better off than most.

So I have switched the springs around to the top of the base. If I am being honest, I think it may have had more flexibility with the springs on the bottom, if not atleast the same. As far as vibrations go, I ran an acceleration test before and after switching the springs around and the ringing is pretty consistent between each. Looking very closely and being hypercritical, I’d say the ringing is slightly better with the springs on the bottom. I think the springs act as a dampener for the bed and reduce the vibrations that the frame experiences. I’m going to keep it the way it was designed though, with the springs on top. Just wanted to provide my findings.

Yeah without the slots you are pretty rigidly tied to the Z posts. With slots the table is a little less coupled. Just know now with a giant print your bed will not compress any springs, that is the part I am most concerned with.

Slots would allow it to pivot more. On the railcore, we don’t use springs at all, just some rubber faucet washers.

Ive been considering doing something like this. Since I don’t see going.non-planar any time soon, not having that freedom of movement isn’t a problem