Starting a thread to document my work to put the Jackpot onto a JL1 laser.

This will be another typically slow build log for me. Hopefully less slow than my stalled before seriously underway repeat printer log.

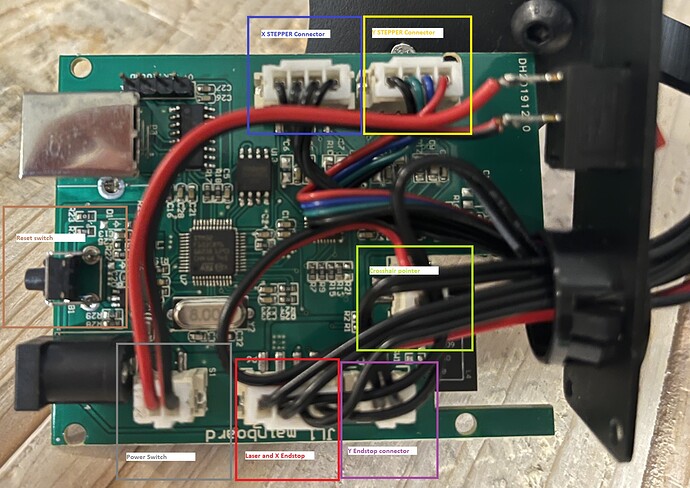

Here’s the JL1 on my too small work surface I’m using at the moment:

That JL1 was a $75 purchase that our own @dkj4linux pointed out to us in these very forums. How cool of him to tip us off about really affordable hardware like that.

I use Lightburn to drive it from a windows laptop, and I converted the firmware over to GRBL. I have a couple of posts over on the LightBurn forum about that because I was too dumb to follow instructions properly and didn’t hit the reset before trying to flash the firmware update. Ended up needing to get a device programmer and unbrick the thing because of my stupidity- but that worked and it is currently running GRBL on the stock controller.

Just to the left of this setup and not visible in the picture I have an assembly table with a really cheap and crappy scrap plywood and dowel protective enclosure I’m thrashing together as I swore to myself I wouldn’t use the JL1 without better protective provisions than using my own OD 6+ laser safety glasses that I bought to use when occasionally working with lasers at work.

There’s too many chances to have a grandkid wander into the garage and encounter me messing with the laser- so not having an enclosure has also seriously limited my experimenting.

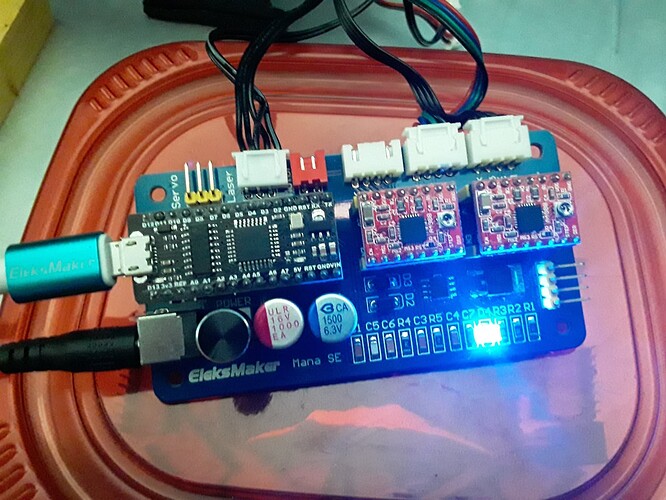

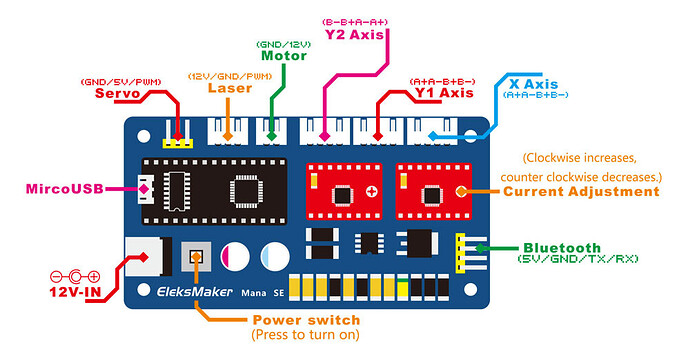

My initial bench testing has some notes in the main Jackpot board development thread.

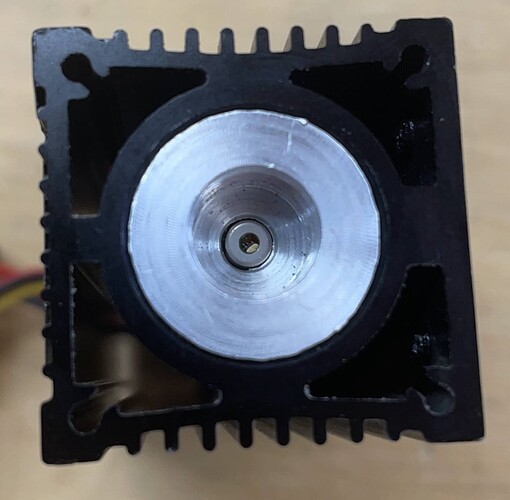

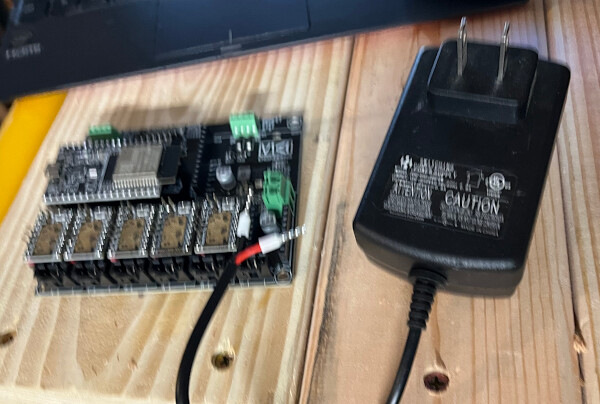

I started playing with the board using a 24V wall wart switching power supply, but since the JL1 comes with a 12V power supply and I believe has a 12V laser, I’ll find a suitable test power supply as I’m not quite ready to cut up the stock JL1 power supply cable.

If I make any notable progress on the cheapo enclosure I’ll post that in this tread as well.

Sorry for the fuzzy picture of the wall wart and ferrules- I didn’t notice the iPhone was having a rare cant focus moment.

I always put crimp ferrules on wire leads when installing into screw clamps. The wires can’t birdcage and get lose, though that tiny wire AWG is probably not likely to ever have that problem on a Jackpot.