I have been asked constantly to let people behind the curtain of a development cycle. Let’s give it a shot here.

“Rules”

This thread will be different. I will delete off topic posts. I think this is going to get very long so I will trim it up as I see fit. Normally I do not do this. So tangents will be deleted, if we are talking about fans all sorts of fan stuff and flow is fine but let’s not get into BBQ or anything.

I am going to hyper focus on one aspect at a time. Each topic will get linked in this first post. When we move on we should have a resolution and an easy to reference marker on why we chose what we did.

“The Goal”

Lastly, this is not going to work for everything, but I will try to accommodate everything we can. If something need a unique part size, I will do what I can to make that an easy to edit CAD part. This is going to be a “best bang for the buck” type of build. If you want a gold plated extruder that is fine, we will try to accommodate that but it will be set up for something more ideal.

In the end this will probably look an awful lot like the current MP3DP. Hopefully not though!

“The Topics”

1- Print volume. Starts here

Decision - X-300xY-300xZ-300(± depending on rail length to simplify BOM). Make it as space efficient as possible, so add-ons do not make for an overly oversized build (parametric build volume).

2- Z Axis drive system starts here

Decision - Belt is fine, E-Z-Brake works (relay). 3-Z steppers (max out skr)

3- Moving or stationary bed, starts here

Decision - Moving bed.

4- Frame material / construction Starts here

Decision - extrusion / hybrid just like it currently is unless (three planes) something comes up to do it otherwise. It lets people have options.

5- Belt - starts here

Decision - 9mm

6- AB stepper position - starts here

Decision - Slightly favoring back of the printer.

7- Top plate or Top rail, side mounted rail - starts here

Decision - Side Mounted.

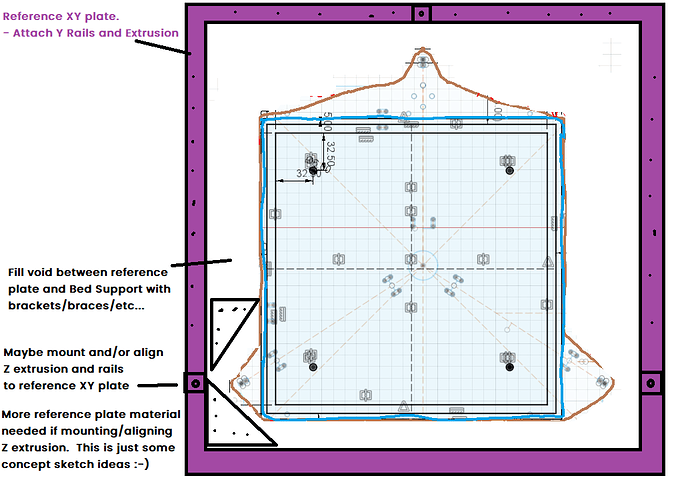

8- Concept XY starts here

Notes - Twisted planar belt, is the current direction being pursued. With the help of Mark R’s ptfe tube splitter.

9- Hot End / Extruder Width before size needs to be added to the default frame… Starts here

Decision - 78mm (hemera) as the “largest”, biqu H2 a great option.

10- X linear rail orientation- starts here.

Decision - Horizontal linear bearing surface, favorable Truck mounting plate.

11- “plate” thickness - starts here

Decision - 5mm plates fit M3x10, M5x35-40 screws and the pulley as shown. Slightly thicker should still be fine (M5x40). Thinner plates will need shorter M3 screws and the pulley flipped.

12- Z axis, linear or V-wheel - starts here

Decision - Linear rails - JRS made a wheeled option.

“Upcoming topics” (not answered yet but came up in the discussion).

- Heated beds, zone heating.

Notes- SSR Gcode triggering for zones reasonable? Any way to trigger other zones to get held lower, is it needed?

Notes

-Klipper 3B and better should be used, the zero 2W also seems to be a budget option.

-Optional Hemera and Biqu H2 mounts built in.

-Optional EBB36/42 CAN Bus mounts designed in.

-Optional V1 Terminal block mount.

-Heated chamber, what limit? Limited by the temp the electronics/stepper/bearings can handle, make sure to print any parts out of a suitable material.

-Gantry linear rail or rail and added “support”? No “support” as designed, room for support under the rail if you prefer.

-Linear rails come in ~50mm lengths inexpensively (obviously you can spend a lot more), chances are you will need to cut one to *75mm to save a ton of money. Abrasive cutting blades work well, cover to keep things clean while cutting.

“Cad” - Source

If you want to get a look at a previous example, here is the 4.1 MP3DP we will be using as a reference. Fusion

New CAD V5, here - Fusion