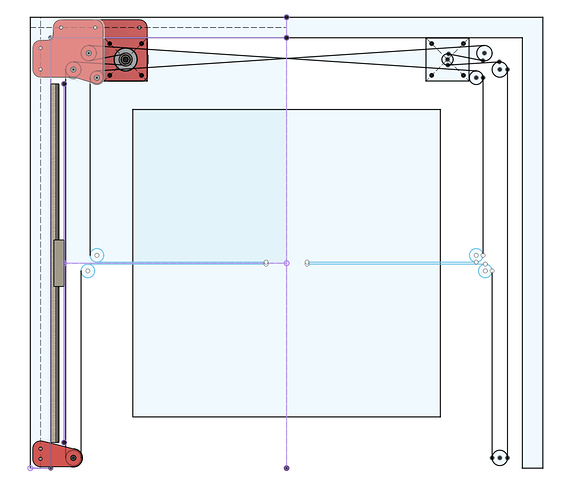

Initial Concept XY

So the Y rails are not set in stone, I just needed to see it.

Side rail as shown - The XY connection is more complicated this way, but I think slightly stronger.

Top or Bottom rail - Easy, can also be a plate sandwich setup, might need two extra screws to make it extra rigid (probably the way to go). The idlers are pretty far away from the bearing surface at that point though.

The two downsides is using MGN9 means upgrading means new rails, and the side panel would need to be offset a few mm or pocketed near the rail. So easier XY connection, “harder” to enclose.

So far all 2D milling, with a few small printed parts as pacers. What do you think??

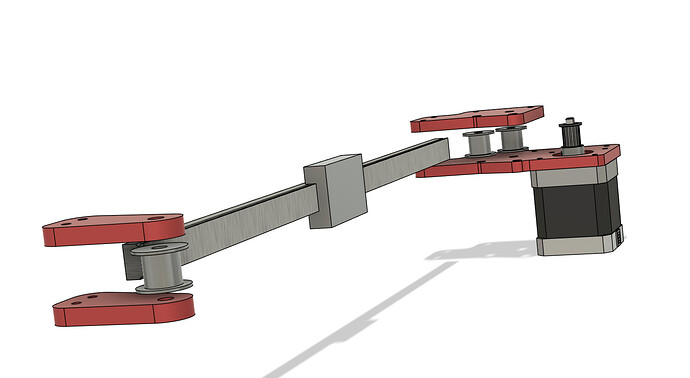

If you are wondering about tensioning the belt, I would guess that the front idler would be the best place for it. A movable stepper means a weaker connection, source of ringing. Tensioning on the core adds a lot of mass…all still up for discussion.

We are still on the Y rails, side, top or bottom (top or bottom is just moving the extruder center of mass up or down and really can go either way).