X rail orientation.

Which way should the X rail go? Just so we have rough numbers a MGN12 is 27mm wide (across the bearing face) or 13mm thick (mounting surface to bearing surface)?

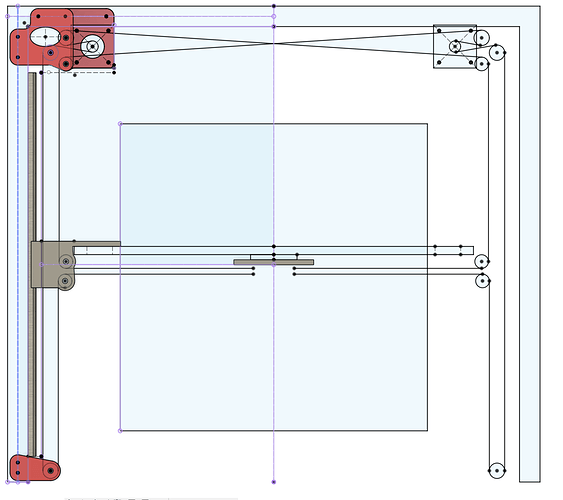

I have been roughing in a couple of things that are not set in stone.

This is just showing what the vertical rail looks like with a 78mm wide plate facing forward.

The belts can move, so don’t pay too much attention to them, the gap between the across the front is mostly fixed though.

Facing the way it is shown, you need to also offset for screw head thickness from plate to bearing.

Facing the other way you need to make an extruder holder that comes around the rail.

Laying the rail flat (the V4 way) you need to make a 90 degree corner. Horizontal (bearing face) to vertical (extruder orientation). It does not cost much in terms of space so if any so other than that what are your thoughts? To me either way is fine, I like the idea of a single flat plate for the main core, but we have a lot of options at this point.