Well, those last 18 days have flown by!!!

So I’ve made some progress with printing (some of) the parts, and then ran into a whole bunch of headaches with the printer.

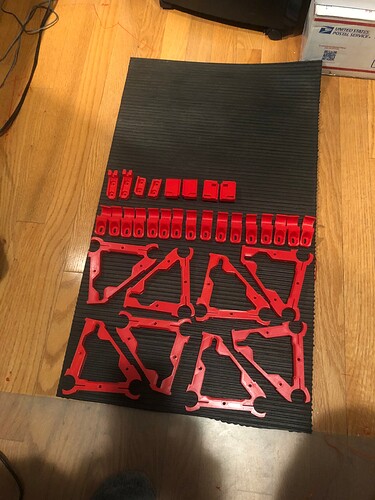

The good news is that I managed to print off all of the Y Rail Brackets, inner X Rail Brackets (50% infill ones not done yet) and the Y Belt Holders/Endstops (not sure if the terminology is 100% correct, but hopefully you can tell from the picture what I mean…)

Things were going along pretty well, and I was feeling pretty good about the quality of the prints. Until I noticed that the last few X Rail Brackets were showing some weird lines (layer shifts?) in the middle of the prints

I spent a LOT of time trying to figure out what was happening. I had noticed that the nozzle was contacting the infill during travel moves, so I had made some setting changes in Cura to add Combing and Z Hop, so I wasn’t sure if the lines were a result of the nozzle contact, or from the setting changes.

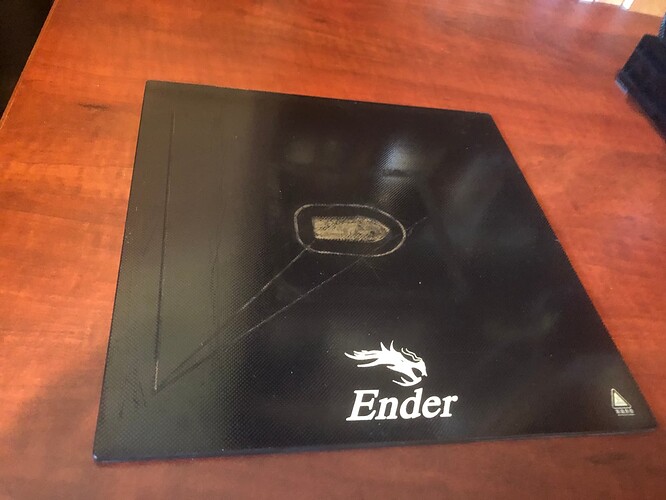

I started to look at the first layer setup, so I re-leveled and trammed the bed (several times), and I noticed that the bed had some fairly serious warping when measuring with a dial indicator. The waviness seemed to be most noticeable near the edges, with the corners raised up and the clip locations (x2) lower than the rest of the bed. The center of the bed also had a noticeable dip.

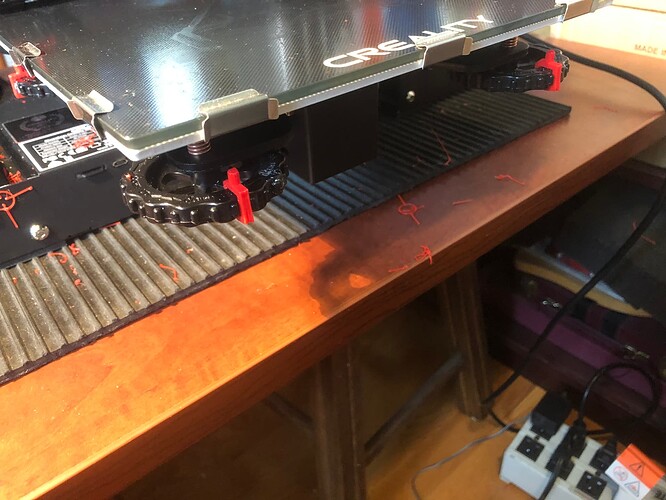

Creality units ship with only two clips, so I bought/installed several more clips (3 on each edge).

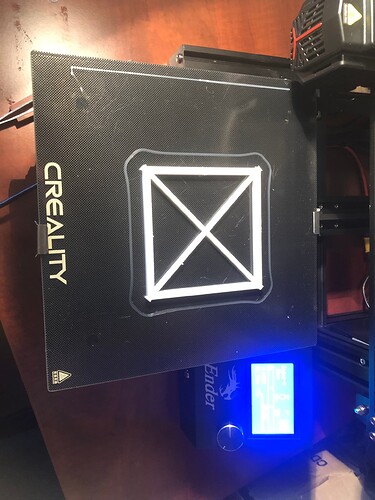

The units also use only 16 points (4x4) for the bed leveling mesh (Bi-Linear), so I went down the rabbit hole of configuring Marlin to use UBL bed leveling with 100 points (10x10). That took way longer than it should have, mostly because Creality has not provided the source code for the newer models of the Ender 3, and the only “example” for my model that I found on Github (Marlin Firmware) had a few obvious errors and was not set up at all to use UBL.

I spent MANY hours learning all about G29 codes and how to edit and compile .h files. After repeated mistakes and failures, I finally got the configuration pretty close to how it needed to be.

I tried a few test prints, and the results were HORRIBLE! Blobs, stringing, gaps in the first layer, you name it!

I found a bunch of issues:

I found a bunch of scraping marks on the plastic piece at the base of the Power Supply

It seems that the Power Supply doesn’t sit straight on the vertical gantry beam, and was twisting into the path of the bed, where it was getting scraped every time the bed got near the Min Y position. I had to shim the Power Supply on one side with aluminum foil to straighten it out so that it was parallel with the bed.

I also found that the PLA had become moisture soaked from sitting on the printer too long, so I had to set up a makeshift dryer using the heated printer bed and a cardboard box with some vent holes. That and cleaning out the nozzle/extruder seemed to make things a bit better.

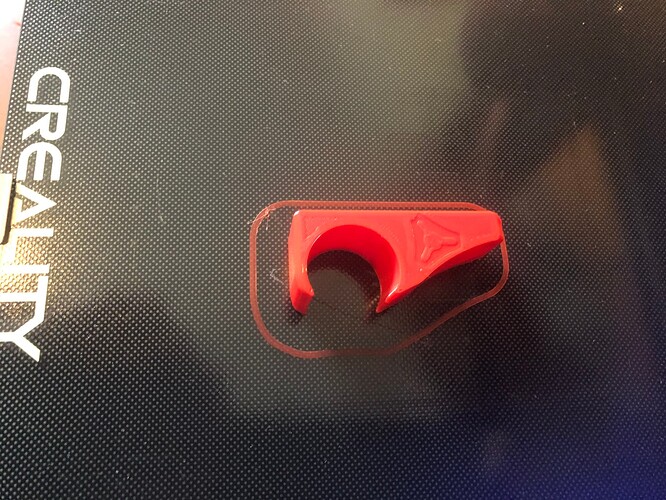

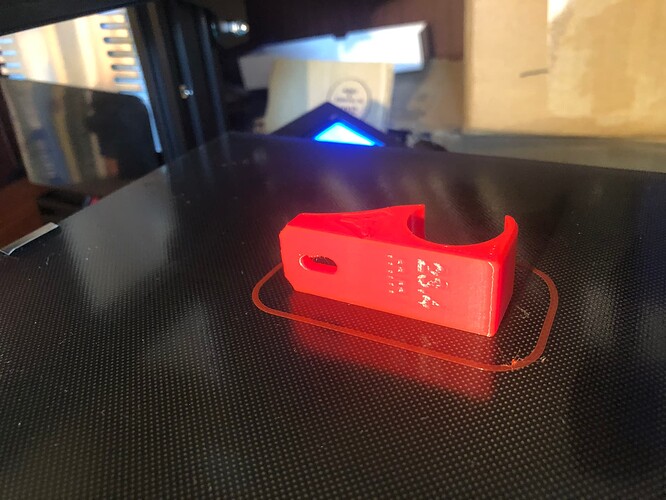

I also found that the bed adjuster springs weren’t tight enough, so they were spinning loose during printing, or whenever my hand brushed against them when changing the SD card. So I tightened them up so that they were about 90% compressed and printed some parts that attach to the adjuster wheels that I can use as a visual reference to see if they moved

(Once I get the printer working correctly again, I’m going to print and install some locks to prevent the adjusters from moving at all).

Lastly I noticed that the nozzle moved around when I touched the Bowden Tube/wires at the top of the nozzle assembly. I took of the fan cover and found that the two screws that hold the nozzle/heat sink to the assembly had come completely loose! I tightened them up, and I’ll check them every couple of weeks going forward (there may be some Loc-tite in their future).

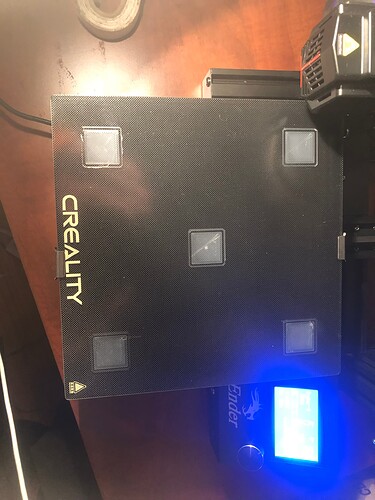

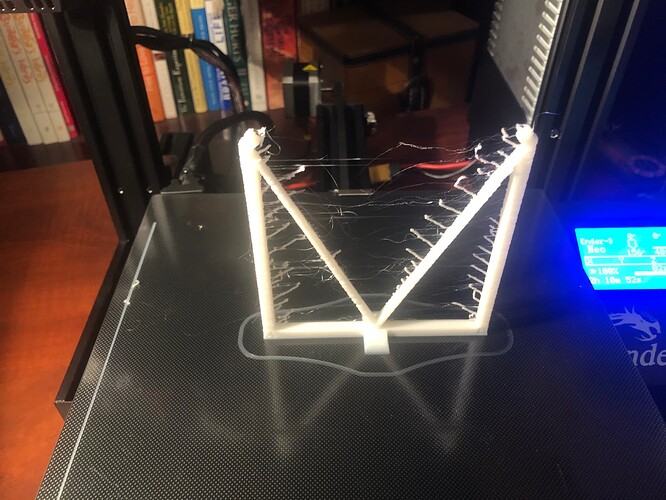

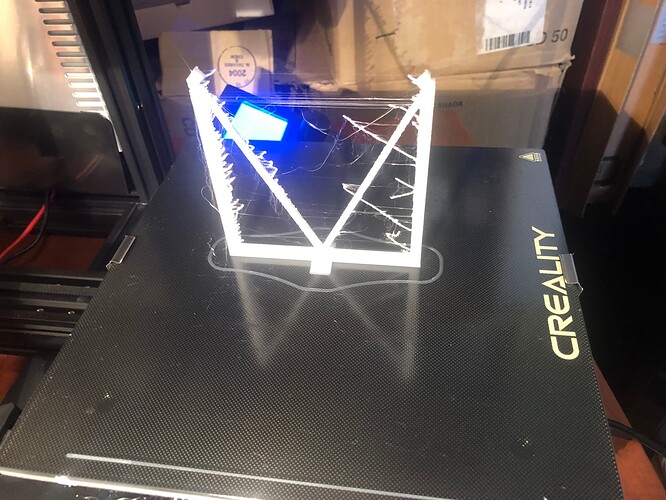

So after all of that, I’m getting closer to having the printer back to working condition. I’m still dialing in the bed mesh using G26 mesh validation test print. Parts of the bed are adhering well, but some other parts aren’t there yet, so I need to manually adjust the mesh points until it is consistent across the entire bed.

Kind of challenging when I only have an hour or so in the evenings to work through all of these issues, but so far the challenge has been fairly rewarding. I’m learning lots about 3D printers, Marlin configuration, g-code, and a bunch of other stuff that will hopefully help me down the raod when I start to build and operate the LR3.

Ciao for now!