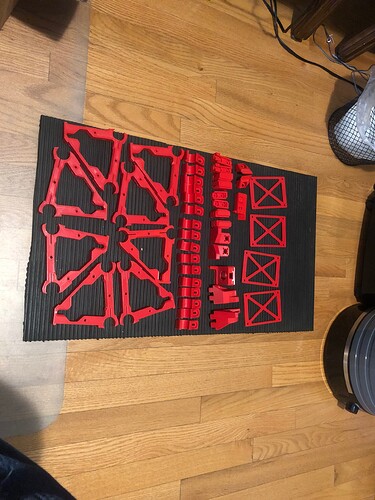

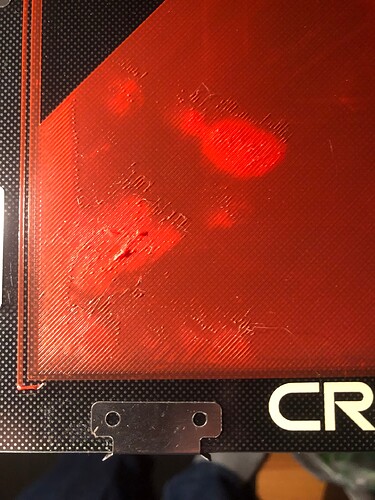

I do not think ot is coincidence that those showed up where the M5 screw holes start and stop.

So what changes there?

Theories:

- This is where the slicer goes from one large part to 6 smaller ones, and it disrupts infill.

- Interior perimeters become exterior ones (around the center triangular holes) which reverses the print head direction there, and it’s pushing other stuff out of whack.

- The corner immediately before the problem area goes from being a right-hand curve to a left-hand curve, and there is something allowing backlash in the mechanism.

Any/all of these would have a root cause of some backlash or slop in your printer’s movement, and this is just the point where it shows.

I would check the X and Y drives of the Ender 3 for any play in the belts. This really looks like the kind of crap that my first printer used to do when the drives got sloppy (which they did constantly because it was a particularly crappy I3 clone.) In particular, check the drive perpendicular to the worst face of the part as it prints.