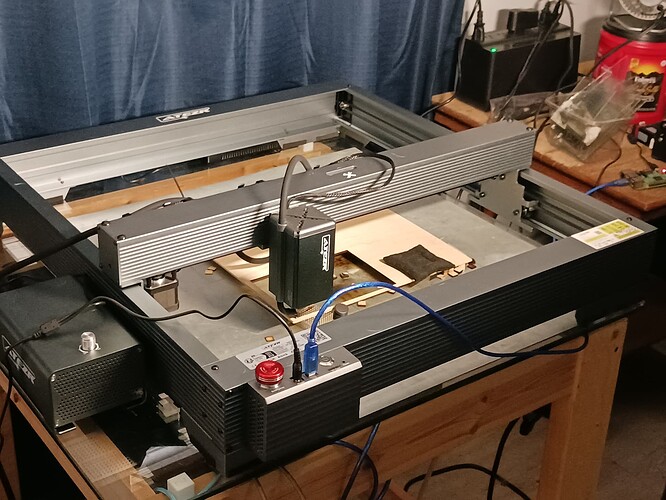

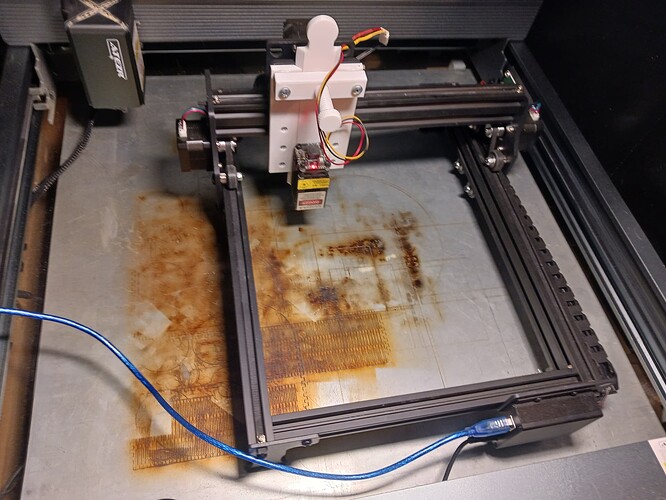

Over in @robertbu’s 40W Diode laser module thread, I shared that I had finally made the leap to a 20W quad-diode machine… the Atezr P20 Plus laser engraver. A higher-end machine, it represented a definite step up from the Neje A40640 dual-diode laser modules/machines I’ve previously plugged. I was a fairly early adopter of that laser module (and IIRC so was Robert) and I’ve had nothing but positive experiences with it. But this new laser machine is a “beast” by comparison… it’s all-metal , big (430mm X 430mm work area), sturdy, fast , powerful , and easily put together with 25 - 30 screws. It comes complete with air-assist , a fancy touch-screen display (which I detest and, thankfully, is not required to use the machine), runs Grbl 1.1h , and is Lightburn and V1PI/CNC.js compatible, right out of the box.

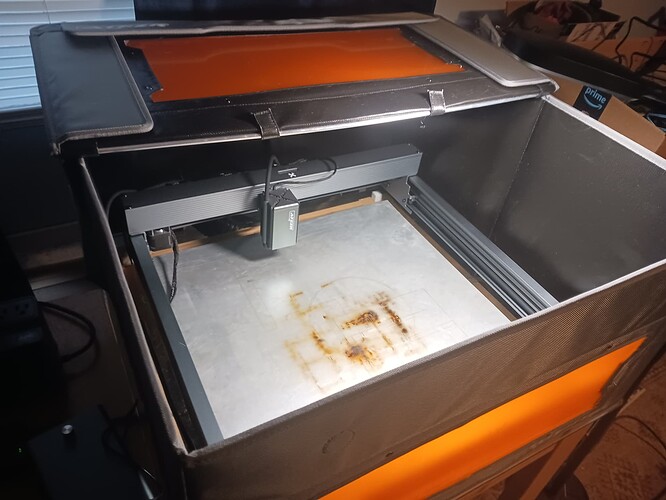

My only “gripe” was that I wasn’t far-sighted enough to realize that the ability to cut longer jobs and thicker materials indoors was going to be accompanied by much more smoke than I’m used to. As a result I had to endure an additional waiting period to come up with a smoke-extraction solution before I could really use it as intended. But, thankfully, Atezr already had that covered… an enclosure designed for this machine that works quite well and is far better and cheaper than any DIY solution I might have concocted.

In addition to some early smoky tests I did indoors…

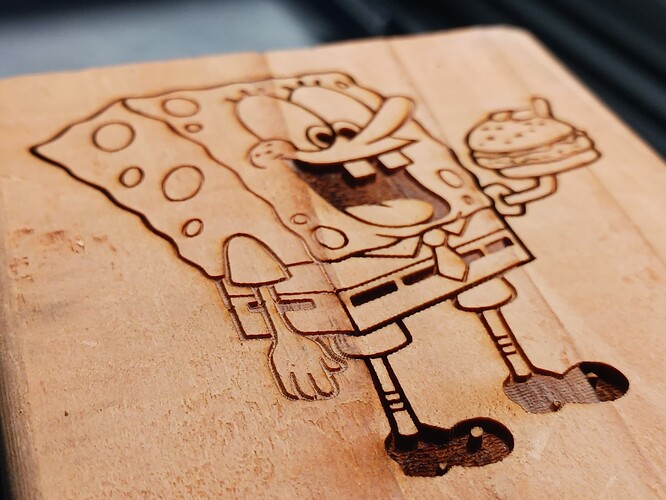

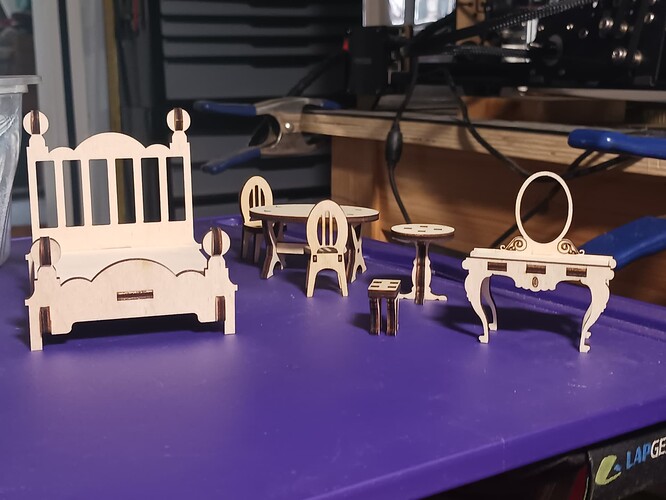

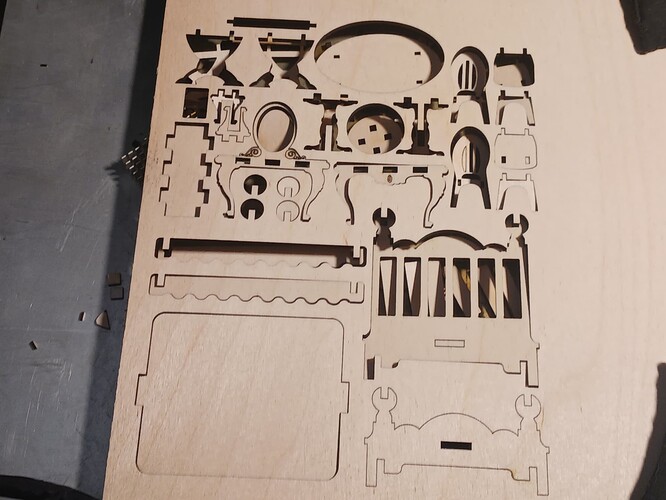

I’m now able to do smoke-free jobs for important people, such as my grand-daughter…

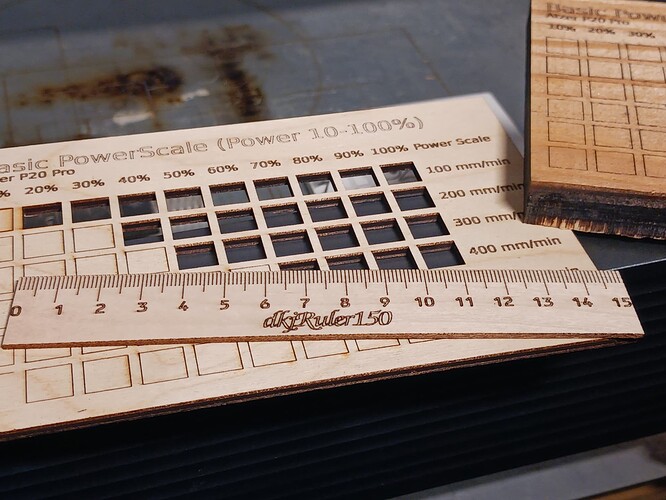

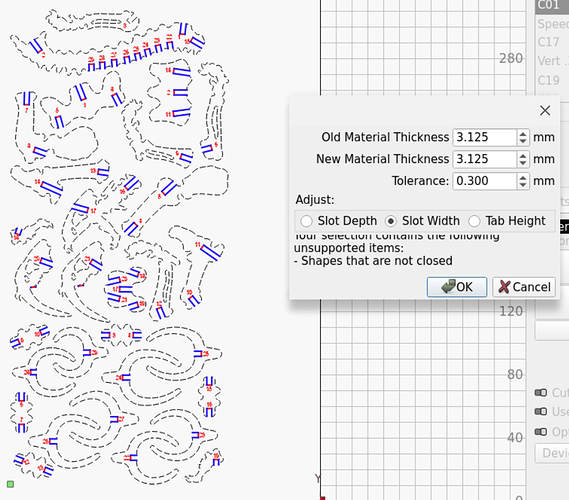

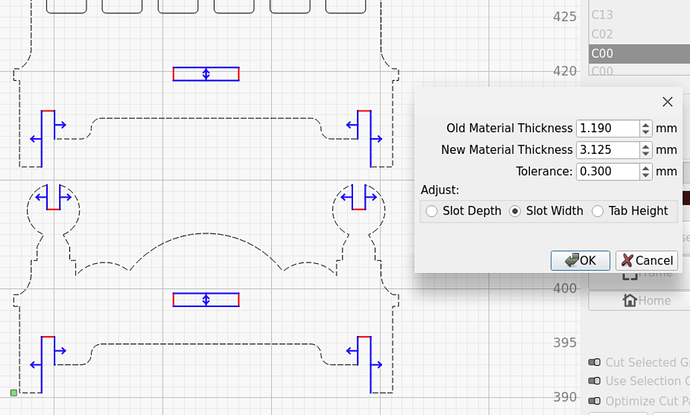

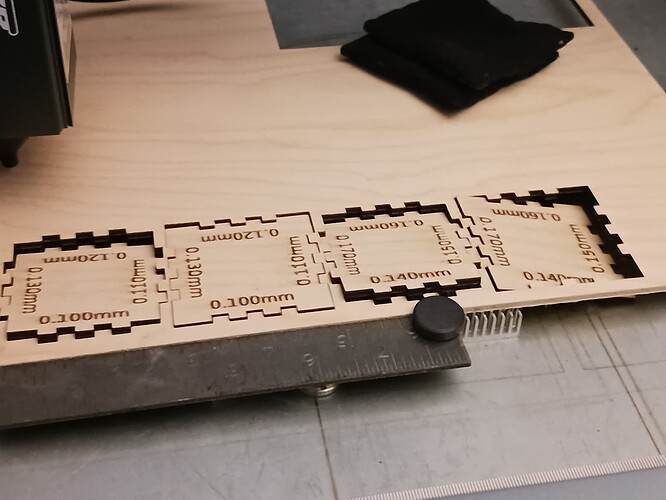

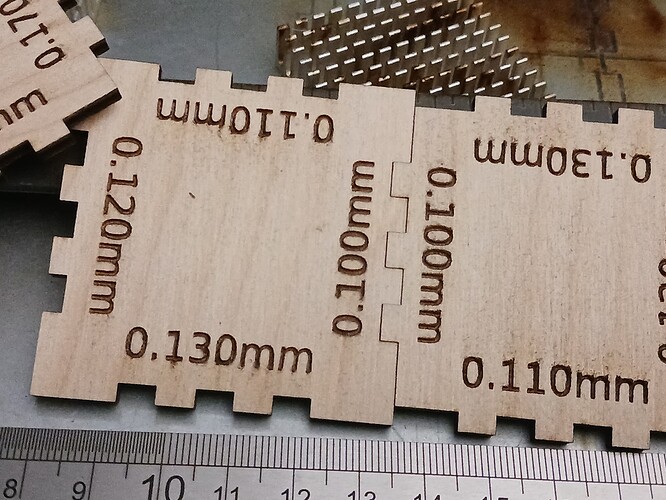

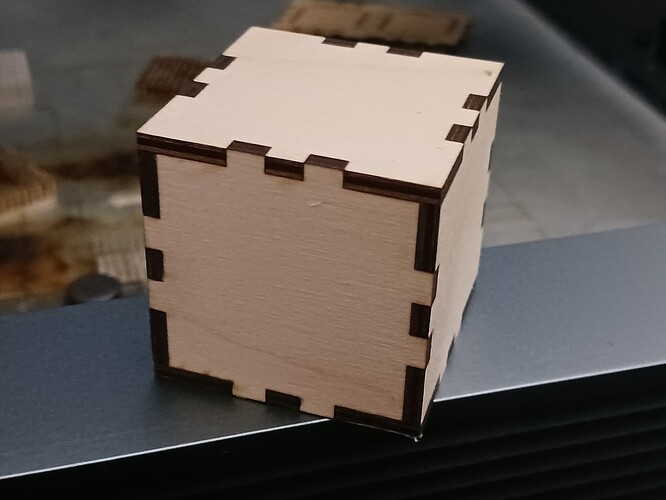

All these pieces are about a 10 minute cut in 1/8" plywood at 400 mm/min, 90-100% power, and a single pass. I used Lightburn to do all scaling and adjusting for 1:24 and 1/8" plywood…

Other than the effort involved with adding a new exhaust vent to the window where my CO2 laser is already vented, this machine has been absolutely flawless in its assembly and operation. Granted, it’s a higher-end machine ($1199 + $189 for the enclosure) than I’m used to but, just as with my Prusa MK-3S 3d-printer, I’m loving the power, convenience, and intelligent design right out of the box. At this late stage, I’m appreciating not having to fight and struggle to make the machine more than it was when it arrived… it’s really nice, as is, and I couldn’t ask for more.

Diode laser technology is progressing rapidly… now that they’re figuring out how to stack/combine multiple laser diodes into one beam. Four, six, and even eight-diode laser modules are now coming on the market and they’ve rapidly become more than just “engravers”. Although my new 20W quad-diode laser machine has already been rendered “only modest” by comparison… I’m thrilled with it anyway. It’s a fun machine to play with… and my grand-daughter approves. That’s good enough for me.

![]()

– David