Oh and i think it should have a new topic for its debut

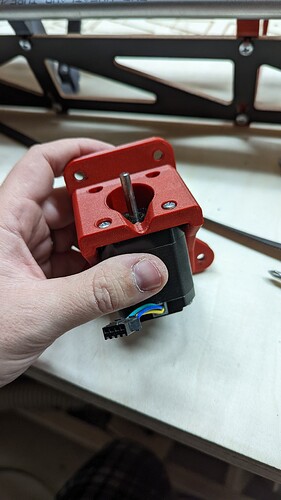

I haven’t had a chance to leak anything. Here is a motor.

I installed this one the with the wires the wrong way. I had to take it off and share. I may be the slowest building them. There have been some good cuts. No reports of performance issues yet. We’ve complained about everything we possibly can (I have, at least) and I haven’t seen any show stoppers just yet.

Ultimately, Ryan needs to be confident that he is ready to release. He needs to have any changes to the parts done now (within reason, but changing a file now is 20x easier than later). He needs to have some stock to sell too.

We are all aware of how excited people are. I am confident it will be released before Christmas.

In the background I see what looks like cool pants. All I have are jeans and I need something a bit more interesting.

I WFH, I have the best grown up pajamas.

Honestly, that was information leaked that I wasn’t expecting.

I can’t friggin wait to start printing/ cutting new parts for this revision!

Concete floor in my new workshop gets poured tomorrow (weather permitting), and a week after that I’ll have space to start planning out my first LR!

I’ll be a day 1 add-to-cart for the v3 kits, and will start printing the printable parts as soon as we can get our hands on the stls.

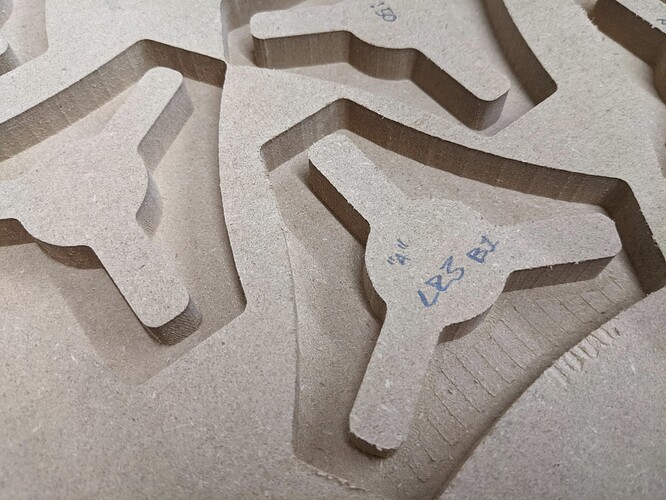

So check this out. I ran some speed tests, this is the result of this gcode Cnc race! - #107 by vicious1 this Gcode is from the fastest cut I made on the Primo with an 1/8" bit video.

The Primo cut was a bit better but the Primo is also 14"x11"x3" cutting area, the LR3 is 48"x25"x3"

Very happy with this.

It is a worse bottom finish than the Primo’s, but both have some wavy stuff going on the LR3 pocket seems extra wonky on that one side I am investigating it.

Dimensionally pretty good? That looks better than my LR2 haha so I’d be happy haha

Nice linear rail ;). Have you trammed it or was this more or less built and run?

I was invited to apply for a new internal position, so I ended up in a panel interview with a bunch of folks I already work with and our company has been like 93% WFH for 2+ years. I started out by saying it had been quite a while since I’d done a job interview in my bedroom slippers. Got a nice laugh.

Hope you at least had pants on

I have been WFH since 2014. My best advice is get comfortable pajama shorts. They are the best in the summer.

We are in full trial mode now. An issue was discovered that I had never even considered a possibility. Glaring mistake on my part. I am trying a possible fix now. Builds are getting dirty, but a 4’ span proves itself to be more difficult than I expected.

am i going to get told off for wanting a 5’ one? thats what my LR2 is and the size of my custom table… (table cost more than the LR2 as well haha, so im not changing the table  )

)

A slightly wider table isn’t a problem. Even the LR2 suffers a bit from the geometric progression of flexibility, which is one reason why the X axis needed to be the shorter one. That’s a bit more important now, is all.

Besides, solutions are coming!

Anyone have some time to run , Cnc race! on a LR2 In the center of your X span? I would love to see the numbers feedrates you run you get and for what length X span. If possible, I would like to see at what point dimensions or surface finish deteriorates. Total time is of no concern, just at what federate the surface finish breaks down.

Jeffeb3 has a LR1 in that thread, 4’ S span, that hit “This was 20mm/s, 90% stepover, and 12mm DOC. 1/8” single flute upcut."

Barry’s 4’ span LR2 in that thread, actually hit 50mm/s with a 1/4" endmill when things started to deteriorate.

I am trying to get a good gauge of what is possible. Turns out my LR2 was not running nearly as well as Barry’s even with a shorter X span.

Would it make sense to standardize some settings? Like 90% stepover and certain DOC, maybe have to or three groups of settings to try out (90% stepover&12mm DOC with 1/8", Ditto with 1/4", then repeat with 50%).

I’ll have some time to do a trial or two on Monday. I’ll go with full depth and 90% stepover with a 1/8" bit since you mentioned it above but if there are other settings that would get you better information faster, let me know.

(My printer is only somewhat dialed in; if you need a not-best case scenario on printing parts, happy to oblige)

That is probably a good idea. The race was all about free form Material Removal Rate. For this I have been doing 70% step over (probably the cause of the poor bottom surface finish). Full depth of cut. I think if we get a a few people to push the limits a bit I can get a good sense how much better this one is…or if it is better.

So lets do any endmill size 12mm DOC or as deep as you can, in MDF or particle board, 70% stepover and as fast as you can.

oh @vicious1 as soon as i get som 18mm mdf re stocked im jumping in. my 3d printer is ready and Fillament loaded to start printing the parts i broke

Sounds like LR3 is coming along nicely, hopefully what that issue was you ran into wasn’t too much of a headache. Any idea how close LR3 is from release?