Philipp

You’'ll be happy to hear I set the LR3 back up after being in storage since may, got it back in my shop and hooked up, and it ran perfectly.

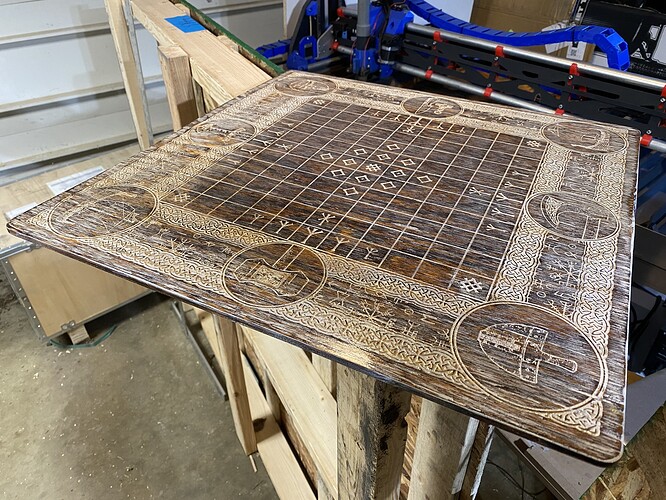

A friend saw my little ‘Bee’ honey board in our kitchen when they came round for our kids birthday party, and really liked it. A couple weeks later, she texted me to ask if I could design and make an award plaque using the same motif, and a couple extra things, and I said sure.

Thinking it was a one off personal thing for her kid or something.

Oh, no. No, Lol.

She works as a support team lead for a Hospital here in Atlanta. And she wanted 12, as staff appreciation awards. However, she is the Lead person for the whole network of 5 hospitals, so I just got the cheque paying the invoice for 63 of these plaques!!!

Got until October 26th to batch out the first set of 15, and then December 6th for the remainder. Big job, but an amazing score (turned out they had to bid out to 4 companies for their finance dept to be happy) with huge advertising potential.

Yesterday i collected lumber, tomorrow I start the cutting.

With that said- I still want to do the v-carve inlay stuff, so ill start bugging you once I get this order completed. I have plans to start making the big inlaid butcher blocks I’ve been talking about for years now.

With my income from this job and the previous stuff ive used the LR3 on, the shop is about to get a couple major upgrades… a 15" resaw Bandsaw from Harvey and a Laguna 16/32 drum sander. That’ll complete my tool list for the shop and let me do everything i can think of, except for turning bowls. Although i plan to learn how to do 2-sided carving with Carveco Maker very soon.

@vicious1 - dude, your invention is allowing people to pursue their dreams and I am so very grateful I was able to get an LR3 and become a member here.