DAng that looks goood!

Any chance you still have any of these left? Looking to set up a shop computer for my son’s CNC…

I’m not sure what shipping is going to be like from Norway to the US, but I’ll be in Denmark at the end of Nov, maybe you can send it to a co-worker I can pick it up from?

I’ll look into my stash tomorrow! Right now I’m at our cabin, and I don’t remember how many I have left.

These questions should be their own thread or in your build thread, this one is Neil’s. ![]()

Yeah true, I will shift it. Bear with me lol

Done have shifted my question to new thread ![]()

Sorry Neil

nah, take it up with philipp, he’s the one who complained, lol. He just doesn’t want me getting the traffick ![]()

I like conversations anywhere, tbh.

I am the guardian of this thread until you are truly back. ![]()

Hail Denethor, steward of Gondor! ![]()

![]()

![]()

No, that guy is a di… dummy. ![]() Also, I am able to eat tomatoes in a non-gross way…

Also, I am able to eat tomatoes in a non-gross way…

woah, woah, woah…

guys, i draw the line at geek stuff. This place is for nerds, take your Harry Potter stuff somewhere else…

Geek or geek not, there is no nerd.

– Spock

Hi guys

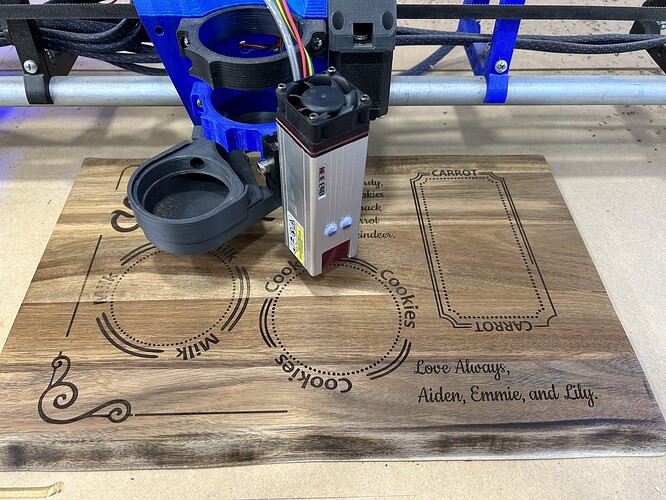

Been running a bunch of vcarve and epoxy boards and a few laser engravings

They are turning into a headache- mainly because I got talked into doing a bunch (8) Santa platters for teacher gifts and friends. Each one is 12x18, lots of elements, and I’m running the laser at 30mm/s 100% power. Ends up being a 4 hour session, each. Faster than that, it skips, so I’m kinda at the limit.

Then, today, I had a situation where the control wire popped off the board 3 hours into an engraving, but I caught it after like 2 minutes. Plugged wire back in and it went back to pew pewing the photons.

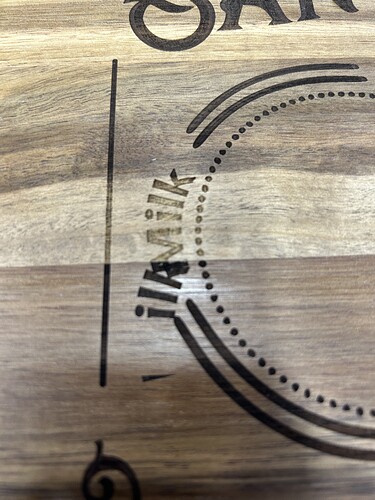

So a little bit missing, but it was a visible part of the engraving. And a lighter engraved area because the wood was sapwood vs heart (light vs dark).

No worries- I’ll let the job end. Without turning anything off, I’ll send it back to zero coordinates, and make a lightburn file with just the missing elements. Load up the new gcode and it should add them in seamlessly.

Except, it didn’t. Ended up about 1/2” off, ruining the whole thing, and now I need to start again

No biggie, but losing 4 hours with what could be a 20 minute job is frustrating.

Wife saw the frustration and asked what could be different, because losing a whole morning of a ‘business day’ if this was paid work would not be sustainable. So I said I should probably get an independent machine, higher wattage, and that way I could run it much faster, 300-400mm/s, and also use the Cnc router at the same time.

Made a great point, and now I’m deciding between an $800 neje 20W diode that does limited cutting (still at 3mm/s for 12mm pine or mdf) or a $3500 100W ruida based co2 that would knock the engraving out in 15 minutes and cut 1/2” ply at 40mm/s…

If I buy it for the business, it’s a tax deduction, plus I could ramp up production and make the money back on product sales

I can’t imagine cutting 1/2" ply, no because it can’t be done, but because I just can’t see that a laser is the right tool for that job.

Since you actually do stuff with your laser is the diode vs CO2 really a question?

The NEJE Max4 is a lovely shade of green though… ![]()

That’s a good price on a 100W CO2 with Ruida controller. I’ve not regretted my investment in mine (which is also a 100W CO2 with Ruida controller).

Which one did you get?

And do you use lightburn with it? What kind of stuff do you do

I’d be getting a CO2 if I was doing a brick and mortar, engrave on demand service- can’t imagine having to do a 45 minute engrave job on a board and telling the customer to come back later, when a co2 could get it done in 10 mins.

1/2” ply or mdf for signs, where customers ask for highly serifed fonts with sharp corners, where a Cnc bit would round off, for example.

If I was to make this a full time business, the co2 becomes a No brainer just for the time savings and ability to batch better, particularly if coupled with lightburn and a camera.

I really want to open a brick and mortar store in the Main Street, workshop in back, with a 1000sqft showroom and art gallery up front. Offer custom, on the spot engravings on the board of their choice, while they wait.

Right now- I don’t really have a space or the critical time crunch to justify it. Even though it would be really cool