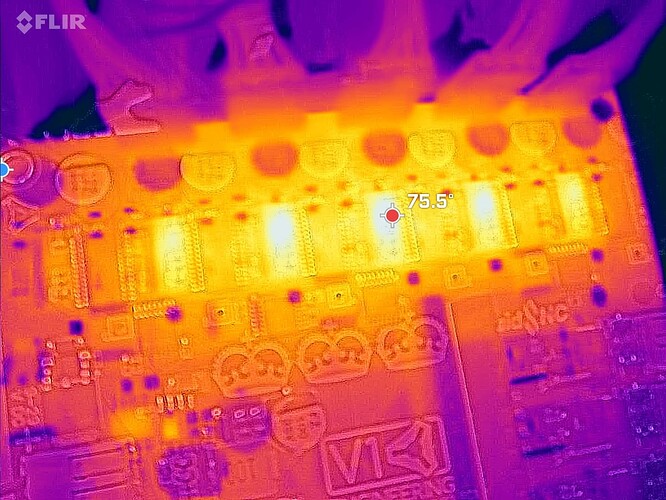

Vias don’t do as much as you might think. They’ll even out the temperature between the sides but don’t increase dissipation as such. There’s actually reasonable thermal transfer between layers without them, especially on multi-layer boards.

How long was all of that running for? Don’t underestimate how long it takes to reach proper thermal equilibrium. PCBs heat up pretty quick but it’ll take potentially an hour or more to properly settle. If you’ve got the ability to log temperatures off a couple of points that’s how I usually judge it, graph it and see when everything has flattened out, or at least dropped to a very flat ramp. You can also pre-heat everything with a heat-gun to speed up the process of getting there…

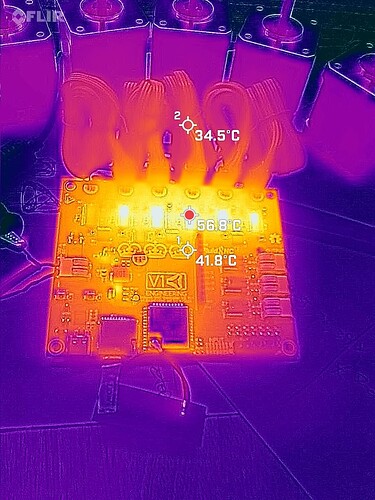

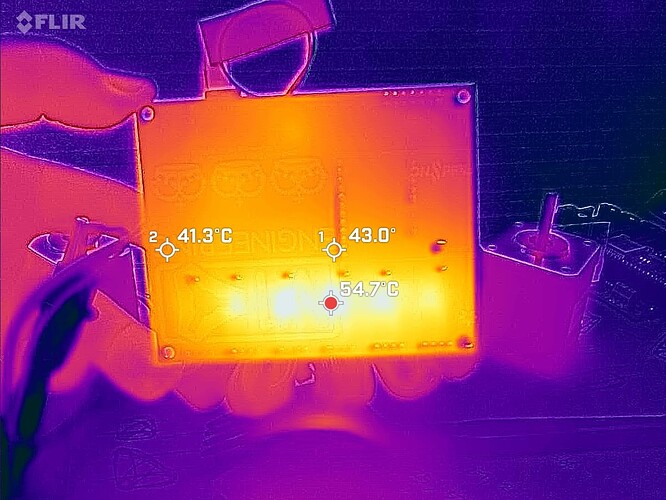

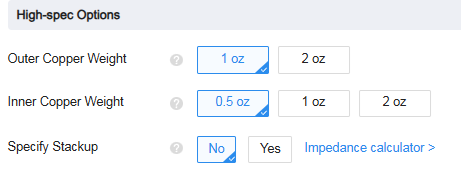

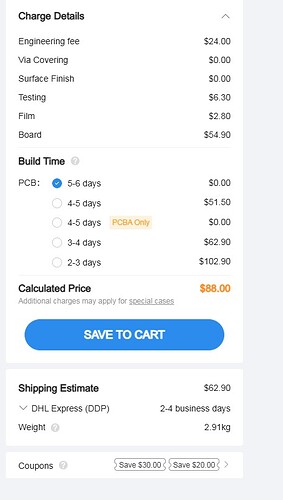

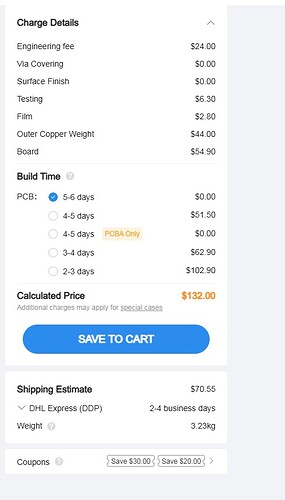

2oz and beyond is remarkably cheap now compared to what it was, while still maintaining usable feature sizes. I’m not sure it’d make a huge difference in performance there because it’s not improving dissipation, as such, that’s a factor of the surface area etc. It would definitely help with spreading the heat out, but that’s already looking pretty reasonable to me… You’d see some extra higher temps around the rest of the board but I doubt that’s driving much of the dissipation, from memory it’s a bit non-linear with temperature delta, so the hot 64C spots are doing a lot of the heavy lifting. I do like working in 2oz, though, it makes some things much easier.

For trying to cool something like this, that’s the way to think of it. You’re trying to spread the heat over the widest area possible. It’s less like cooling a specific thing and more like trying to make the entire board evenly warm…

There is a ton of info out there about dissipation vs surface area in PCBs but it’s all a bit disparate and not the easiest thing to consolidate. I think there are a couple of IPC documents about it as well as some basic calculators. I don’t really have a go-to, I usually just give it a bit of googling. The main issue is that it’s super dependent on installation condition, orientation, etc. It’s also very easily upset by things like splitting a plane with a trace, so it can be difficult to look at a design and go ‘that’s equivalent to X mm^2’ etc.

Just gotta run a bunch of quotes, really. It’s often not super predictable, unfortunately.

Never a bad thing, but it doesn’t actually do a whole lot outside the super high heat-flux regions. The vias are usually plated pretty thin, often only 10um or so, so the effect of a ~1.5mm long 10um thick copper tube isn’t particularly strong when it comes to moving thermal energy around. By contrast, FR4 is actually not ‘that’ much of a thermal insulator because it’s thin sheets with a lot of surface area. More vias will help, but if you can get a view of the top and bottom sides of the design together and matched up, I think you’ll see they’re pretty similar thermally. Vias would only help with situations where there’s a thermal differential top-to-bottom.

Don’t let that discourage you from excessive via use, just be aware it’s not really for thermal reasons!