The Road To RMRRF 2023

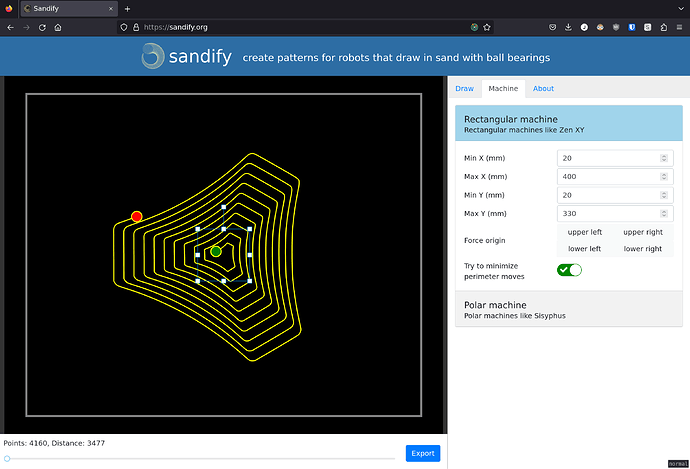

Since there is a rep rap festival in Colorado this year, I wanted to bring something. I decided to build a table top sand table that can sit on a table at an event like this (or a coffee table, or a counter) and attract some attention to V1 and sandify.

Design

The criteria I set for myself was:

- The table needs to be easy to build. I don’t have a ton of time to prepare.

- The table needs to be (relatively) cheap. You can make it out of walnut, or OSB, but making it out of sheet goods means it will be accessible to me and to future builders.

- The table needs to be carried by one adult.

- The glass size needs to be commonly available. I used a weird piece of glass before. And local glass shops will cut any size you want, but they don’t sell custom sized tempered glass.

- It needs to have LEDs.

- It needs to fit on a table.

The glass I chose was from ikea. This glass advertises as “18in x 14.5in”. But it is actually about 16.5"x13.5". I think the hole the shelf is meant to sit into is 18x14.5. I bought two two packs. I will use one for the bottom. So I have two spares.

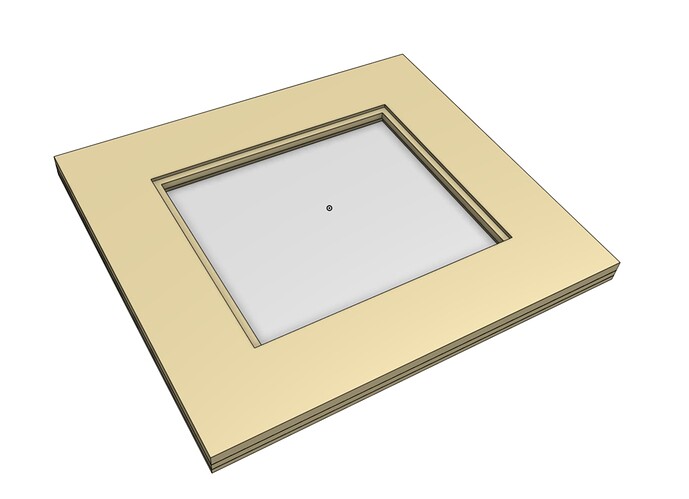

I started with the easiest thing I could think of. A TV-like box:

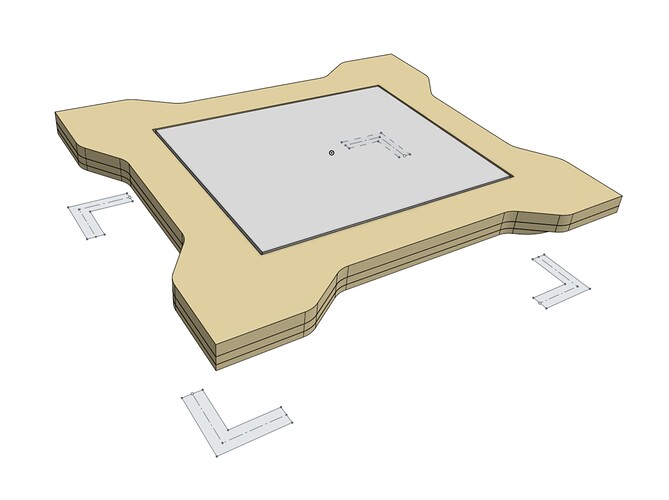

I was thinking of adding beefy hairpin legs. The whole thing looked too bulky. Plus, I won’t be cutting this on a table saw. So I don’t need to stay on straight lines.

With the help of some friends, we came up with printing some legs (more on that later) and cutting some of the extra width off, which will also give you a better look at the machine.

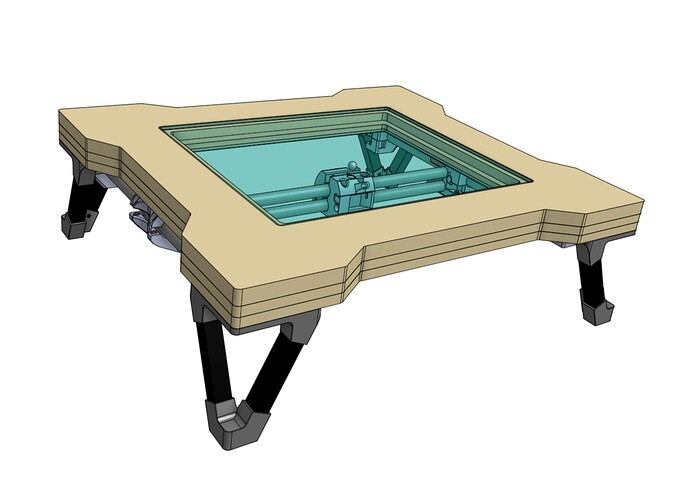

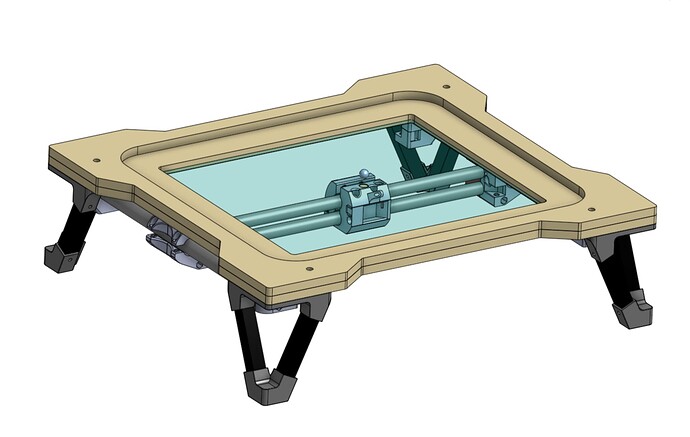

After some more CAD, this is the design I am building:

Legs

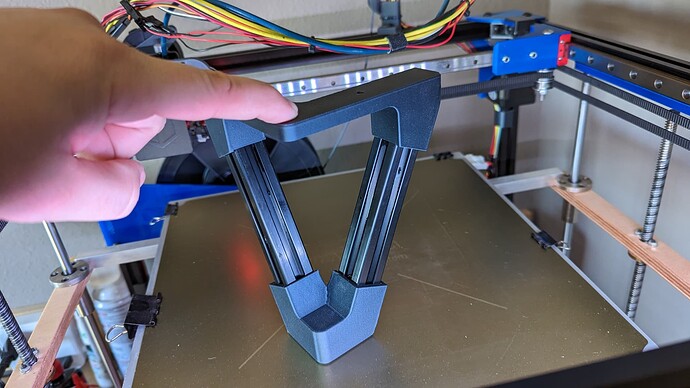

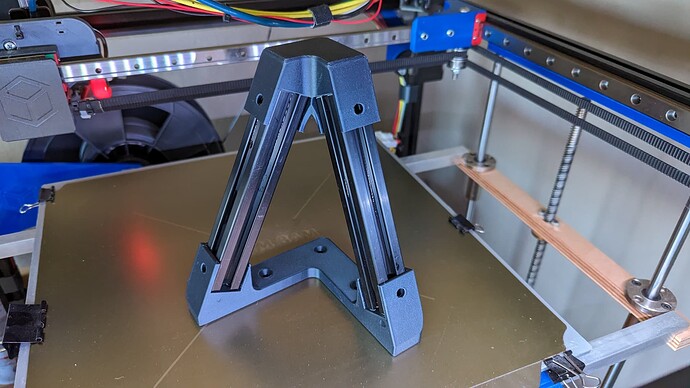

For the legs: I thought it would be fun to use some 2020 black aluminum extrusion. The top and bottom pieces are printed. I really like that the 2020 is not at a right angle. I don’t see that much.

This should also let me print and mount the electronics in the space inside the legs. I won’t know until I am done if I have given myself enough room there.

LED Layer

In the middle of the 3 ply sandwich, I have a smaller layer. This will let me install the LEDS a bit away from the sand, so you will only see their glow, not the LEDs directly.

Mounting the top

The top needs to be removable, so I can maintain the LEDs. I want the sides to be as smooth as possible, so I also designed in some holes for dowels. These should align the three layers after I cut them out. And let me remove the top and replace it with the same alignment.

To the Low Rider!

I decided I would use baltic birch. 3/4" thick for the top. 1/2" thick for the middle and bottom layers.

I cut everything out with a 1/8" single flute bit. I went way too slow, but it got the job done. This pic shows the middle two layers after I freed them from their waste, while the LR3 is chewing away on the top

Here is a pic of the top being carved out. There is a rabet for the glass to sit in:

The depth of that rabet wasn’t perfect. It landed right on the edge between two layers, and I hadn’t used the touch plate to get Z perfect. I cleaned it up with a dado plane.

Here are the three layers just off of the CNC. Not much clean up to do, honestly. I am always a bit surprised when the object looks like it did in CAD. ![]()

Aligning the layers

I didn’t cut the dowel hole in the top layer. I cut the top layer from the top, so there was no way to cut a hidden dowel hole in the top. I clamped the three layers together as best I could, and I drilled down through the dowel holes into the top with a drill press. The depth was set to cut about half way through the top.

Glue up

Today (you’re finally caught up with real time), I glued the bottom and the middle layers together.

I made a goof here. I slathered on a bunch of glue before remembering that the bottom is significantly smaller than the middle. So there was a lot of extra glue (a lot) in this LED area. I don’t think it will matter much in the end. I cleaned it as best I could with some scrapers. If it bothers me, I will paint that inner cavity white. Learn from my mistakes. Don’t do what I do.