same ![]() 48 hours to print everything here we go!!!

48 hours to print everything here we go!!!

DANG!!! Is that two systems or one printer and one cleaner?

What would a full set of parts cost? Asking, so I stop thinking about it, it has to be a lot.

Go big. Laser stintering has realy matured… It won’t be cheap.

(not any part I’ve worked on, but an example of what can be done. Even in titanium if you’re so inclinded and you have a fat wallet.)

Now that would be a show machine.

So the smaller unit is the hoppers for the different materials as well as the chiller. Parts of the machine are water cooled. The larger section is where all the printer jets are.

When i am at work tomorrow I can pull the parts into our system and just take a look at what it would cost to print. We only use the machine for internal prototyping but I could pronably give a ball park on what it would cost.

These guys do SLS printing in aluminium/stainless etc.

$3.4k USD for a LR4 core in Aluminium, $5k USD in 316 Stainless…

Hooo-eeeee.

Yeah we have been figuring out what metals we want to use in out machine and it looks like the stainless steel powder is about 100 bucks a Kg but the powder seems to be about the cheapest part of the print once you facter in post processing.

on printables, I was download 16 or 17 and now it is at 50. that is cool!

IT’S ALIVE.

And also gorgeous af!

While it’s top of mind everyone! don’t forget to like the model and rate it with pictures, it will go a LONG way in helping ryan market the LR4

I posted 2 makes on it, liked it, followed him. Guess I could share it too…

Done! This is a good point.

Shared both my Beta build and my RC3 build as “makes” on Printables. As soon as I can get the full-size LR4 built, I will share it too. Some pics:

Beta:

RC3:

FluidDial pendant on RC3, resting in a cradle I designed:

Hello everyone. Briefly about me. I am Matthias, I come from Germany, I am 41 years old and have been following the projects for a long time. Since the v4 became known, I check every day to see if there is anything new. Now the question arises, which tube is to be used. With the material we make a hook on it. Steel or stainless steel. More decisive for me would be welded or cold drawn?

Thank you very much Ryan for this CNC. Really crazy what you always create

And big thanks to everyone else who helped. ![]()

Greetings, Matthias! Welcome to the V1 community.

Ryan did the beta cycle for LR4 including tubing options appropriate for builders all over the world, including beta team members in Germany.

Check out the LR4 beta program build log from @Tokoloshe , who I’ve tagged in this reply and who I bet can give you great guidance for your build and talk more about your tubing options.

I look forward to seeing your own build log and am curious what you plan to make with your machine.

amzn sale ends in 2hrs ![]()

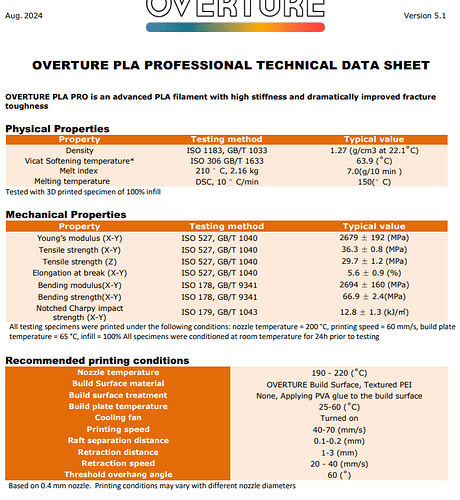

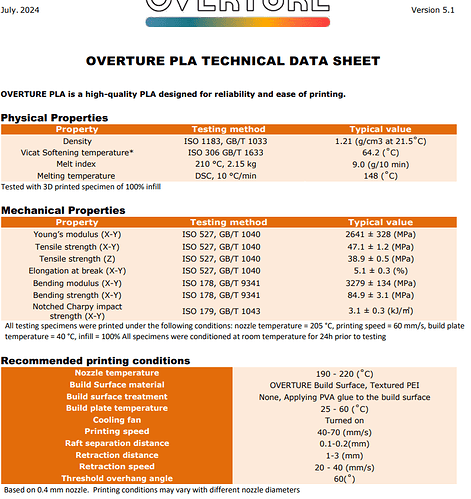

Someone with working eyes and brain able to confirm/correct my understanding… Assuming their numbers are correct, seems like Overture PLA is just as good, or better than Overture PLA Pro from a rigidity perspective? These numbers are from recently created datasheets they emailed me. Looks like they’re actively testing and working on updating their site which currently has Jan 2024 dated specs.

PLA Pro Aug 2024 Tech data sheet: Young’s Modulus is slightly lower than PLA, but made with tighter tolerances.

PLA July 2024 Tech data sheet:

PLA Pro is also called PLA Plus or PLA+, but is different from less rigid Super PLA+ . Stay away from Super PLA+ if rigidity needed.

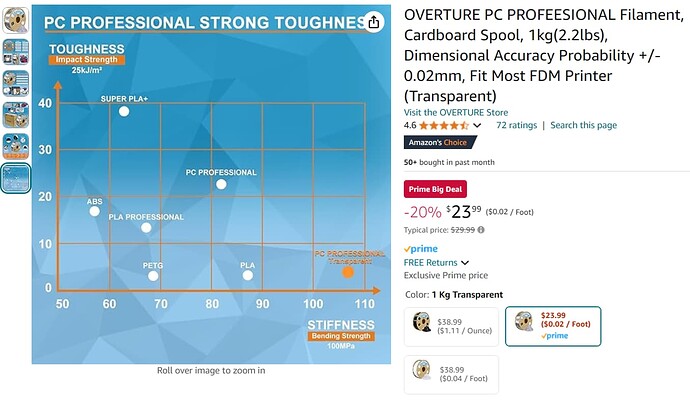

Their easier to print polycarbonate (compared to regular PC) looks interesting from product description, but I can’t find tech data sheet yet, just some pretty marketing graph…

EDIT: Ordered 3 rolls of PC Pro transparent at 11:59pm, saved 20%.

Thank you very much.

I’ll talk to him these days. I hope to start building next year. At least that’s the plan. I will report then.

On the machine, I mainly want to work on wood, such as bowls, cutting boards and various furnishings. Let’s see what else can be found ![]()