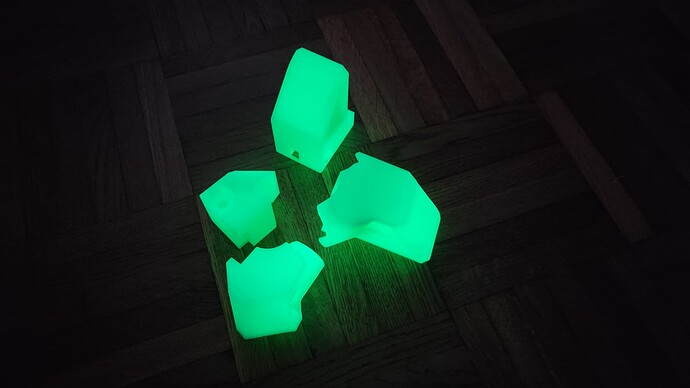

When the LR4 Beta was announced, I was pretty stoked since I had been harrassing Ryan for a while then about any news on the update. The only thing I got out of him was the rail size. While pondering what theme the new one should have I stumbled upon Glow-in-the-dark filament and printed the ghost from Mario, Boo, at the end of May when it hit me: The new one is the Ghostrider.

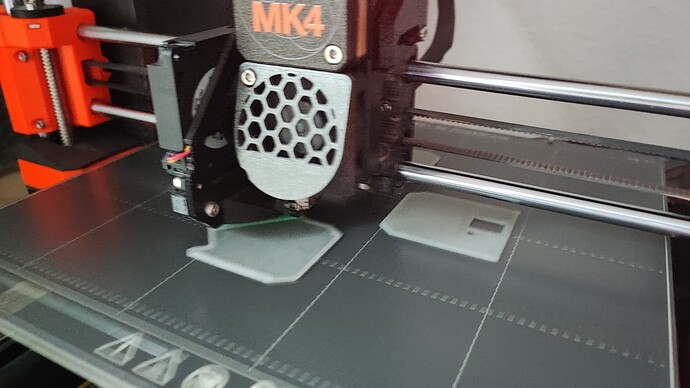

The beta started while I was drinking beer at a Festival, and because @Jonathjon cheated with three printers and had his finished when I got back, I had to hurry after three days of waiting, cranking out parts like a madman and stressing my marriage. ![]()

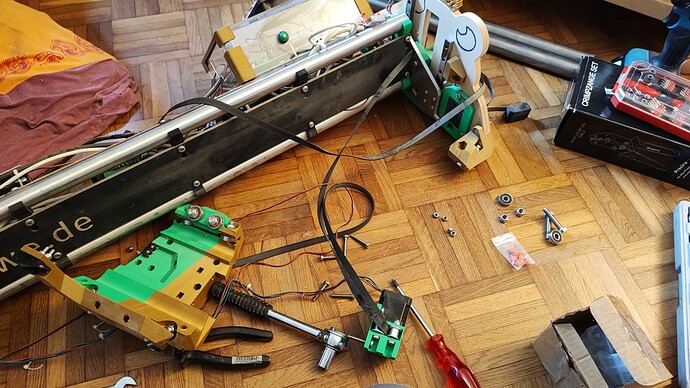

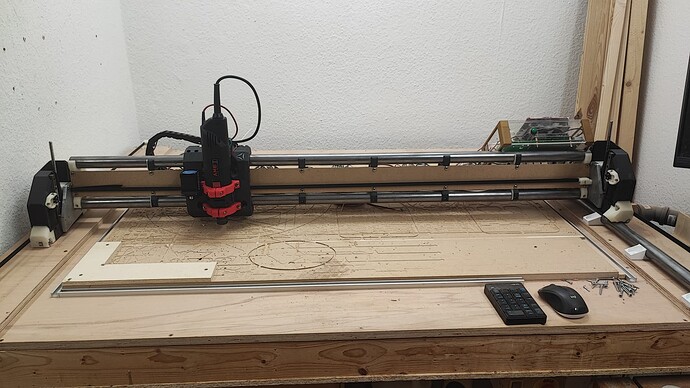

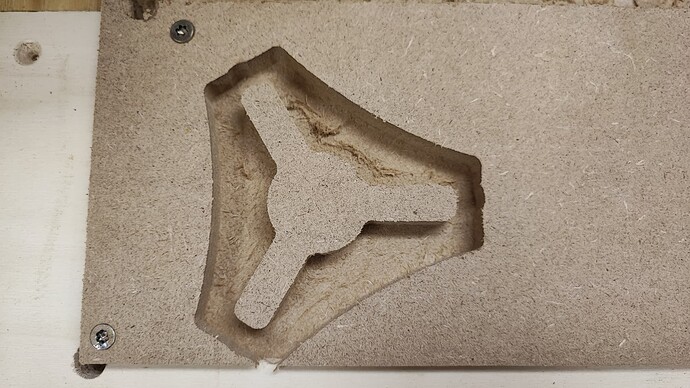

Der Froschkönig digging its grave… ![]()

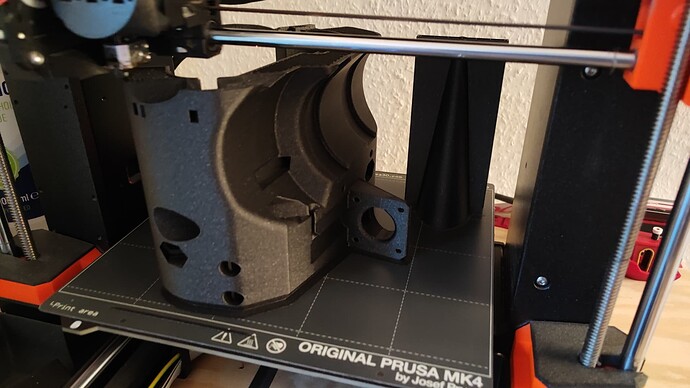

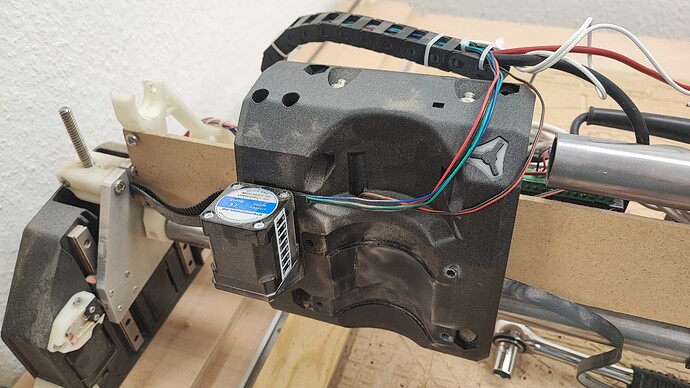

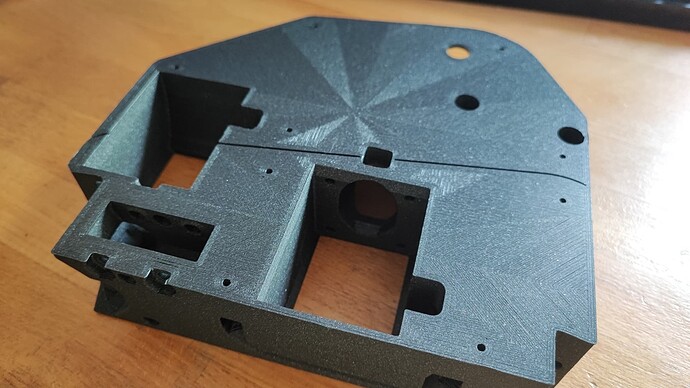

Ghostrider core in progress.

Core done:

Its guts spilled, Der Froschkönig is being dissected.

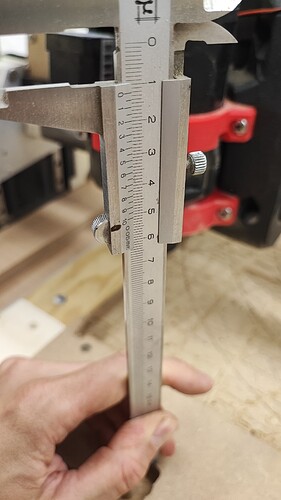

A bit of swearing and begging for the Phillet later:

Quick remix of the toolholders because I somehow misplaced my Makita:

First cut in honour of @bitingmidge and his lovely wife Jo:

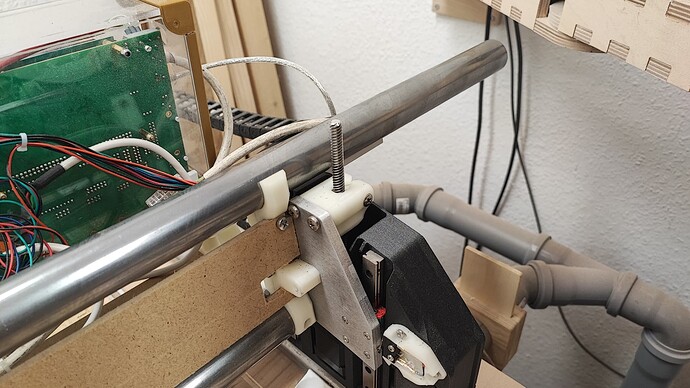

All of the Z movements are very slow, which I never questioned until Ryan made a comment about it (it’s been resolved now, after three years of me not realizing something was off):

Thermo filament to see where the router gets warm:

Since the MK4 prints even on a very crooked printbed, one plate was badly warped. More PLA to the rescue:

First real project, box for the new bike:

3500mm/min, 6mm DOC with a 6mm two-flute endmill? Easy, says the LR4 (I also used round tabs here which suffer from the same problem that engraving does, so no round tabs for speeds that are faster than Z):

That’s it so far. More to come. I still need to shoot a video of the differences in engraving speed. ![]()