@vicious1 Found small typo if you care to fix it.

"Cura based slicers seem to work a little different. Make sure the parts are aligned on your

bad

as they appear in the Printables thumbnails"

@vicious1 Found small typo if you care to fix it.

"Cura based slicers seem to work a little different. Make sure the parts are aligned on your

bad

as they appear in the Printables thumbnails"

Good catch thank you

Ok that’s weird. If I just go to docs.v1e.com and go to the calculator it works just fine. But if I go to it from the link in the LR4 docs then I get the messed up first numbers.

I have spare money today so I ordered the plates and a couple spools. I’m not in a hurry but I like to have parts at hand when I actually start working on something. Nothing irritates me more than get 90% on something and find out the 10% is out of stock.

In an ideal world you would have released a few weeks ago and I’d have a project while I’m trapped inside by the hurricane. It’s not even here yet and I can feel myself getting bored… :laugh:

Added the strut plates to the docs. @jamiek is an animal, look at this thing!

https://vector76.github.io/Web_OpenSCAD_Customizer/strut_plate.html

if any of you beta guys wanna verify I would be stoked!

I checked and X isn’t right:

I have a 45" wide table for x.

I started with cut width. I put in 853 mm because that is how far it goes before it skips (actual machine):

it says:

The y dimensions look right

shows the use of a drop table?

A drop table is where you have the cnc on a frame with an open work area underneath and you “drop” the level of the table under the cutter to accommodate the height of your work piece.

Like here:

this

You put in X work, that spits out rails and table width are they both wrong? I will go verify on mine shortly.

I think my rails are a little longer than they should be, but not much. I used the calculation provided in the part message and made a google sheet to come up with the numbers originally and I was at 40.3" rails and rounded down to 40.25. The calce on the site says 40 even. Is it rounding? I’d just verify that. The table size is just way off.

Ah ok that makes sense. I don’t know why I was confused by that. So bottom line sitting on a flat table you can only get about 2".

Thanks!

The calce on the site says 40 even. Is it rounding? I’d just verify that. The table size is just way off.

Shoot, I just double-checked and the millimeters is pretty good, conservative but that is better than not.

Maybe it is rounding wrong. It does all the math in metric then converts to inches if that is what you checked. It must be some weird rounding.

Okay I published all I got so far on the instructions, LowRider CNC V4 - V1 Engineering Documentation

FABULOUS!

I am proofreading all through it to check for typographic errors, etc.

In these highlight portions in this screen shot:

This part is getting shown as a bullet point instead of asterisk, and I think that could be corrected by there being no space between the asterisk and the first word, in the original code for the page:

No space after the asterisk:

*Not included in the hardware kit.

Space after the asterisk:

- Not included in the hardware kit.

This section heading:

LR2 to LR3 hardware differences for updating your build

…was possibly meant to say

LR3 to LR4 hardware differences for updating your build

This sentence:

Typically, as you face the machine, the left side is Y and Z zero, and the right side is Y1 and Z1.

…was a teensy bit confusing. Would it be better for consistency to say:

Typically, as you face the machine, the left side is Y0 and Z0, and the right side is Y1 and Z1.

This sentence:

- Add the idlers and M5 screws back into place.

…has no image to show what the idlers look like when installed. Surely most folks will know, but might be helpful to show. Someone may not even know what part idler refers to.

This sentence:

- Feed them one at a time out of the slot in the slot in the back.

…was a little confusing by saying “out of the slot” and then “in the slot”…

This section:

- Snug all the rail screws

- Move the XZ plate the full range of motion for each screw to assure there is no binding and everything stays smooth.

…might be enhanced by adding another bullet point saying something like:

- If Z movement is not free, and loosening and adjusting the linear guide rail screws is not helping, consider that the MGN12-H sliding trucks may be screwed down in a non-parallel arrangement. Try loosening one, but not the other, sliding up and down, and retightening.

This part is awesome:

- How did you do, wanna yell at me or did you have fun?

- Now is a great time to take a photo and share it on some social media.

- You are building a robot that will hold a power tool, everyone needs to hear about that.

Finally, as someone mentioned, many hyperlinks are still just placeholders, and several images are LR3 still.

This is a tremendous build doc. ![]()

![]()

![]()

![]()

the z axis moves 100 mm which is 4 inches. If your bit touches the table at the bottom, then you have 4 inches of movement, but can only cut the depth of your mill, which is typically 1-2 inches max. I have a long 2" mill that is 1/4" in diameter taht I bought off aliexpress for cutting foam and It would require this cnc to rest at half way because it won’t fit on the table… unless you cut out the work area, lower your work piece so the 2" bit can hang below the table top to cut and then it would raise up the 4 inches, but still only cut to its maximum depth before the router collet bolt is buried in the wood.

all the math in metric then converts to inches

if you fat fingered and put the conversion of the table from dividing by 25.4 to 20.4, it would be about right…

or it is just off by 300 mm

This new section’s first sentence has two typo’s:

Flat Parts¶

Strut Plates¶

You can assemble the machine using the printed temp strut plates and use the machien to cut it’s own strut plates.

Re. default values on calc tool

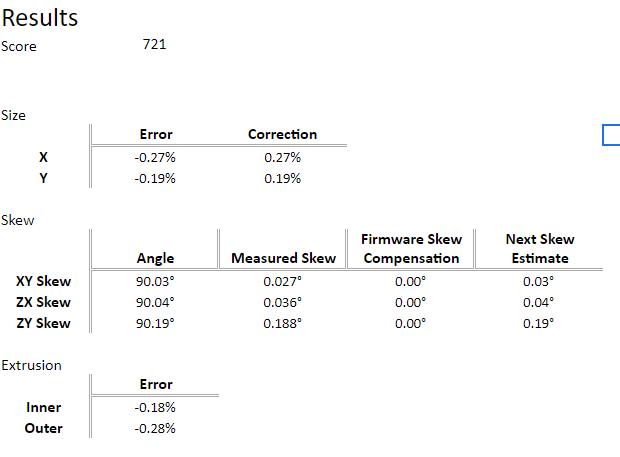

I visited the calculator, and it seems to load defaults correctly for me:

Created separate lowrider-4-calculator-feedback-edits-status topic to track LR4 Calc feedback, edits and status.

Okay I added a few changes and got one tool mount on printables, Makita 701 Tool Mount and Dust Shoe for the LowRider CNC v4 by V1 Engineering | Download free STL model | Printables.com. I’m done for the day. Thank you all for the wild ride, it has been an insane day!

Hopefully tomorrow we get a full and proper release!

For the 29 of you that did not get your order shipped today, Tomorrow should be your day!

I’m glad I asked since I was getting this all wrong. So, yes the cnc has 4" of travel, but taking into account that standard mils can be up to 50mm that cuts your depth in 1/2 unless you allow your table to drop to handle bigger mils. Did I get that right?

Tomorrow is fine for shipping, so is next week ![]()

Wonder how many sales the CaliLantern person got the last few days haha, i bought a copy to test my X1C. Seems pretty decent? Decent enough for an LR4 yeah?