I have no practical knowledge of VFDs. I’ve never owned one. But, every time a VFD question comes across the forum, I’ve spent a bit of time in research. I find them an interesting puzzle.

Read from VFD

… LCD screen that will display the RPM. My VFD doesnt give this information …

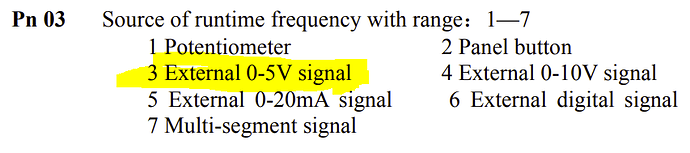

Are you sure? According to the manual you reference, display/adjustment item Pn 01 goes from 1 to 30,000. That sounds like an RPM setting.

If you are setting the frequency on the VFD and just need to map those values to RPM, then you can use a tachometer like this one. That is what I did with the routers I’ve used on my Burly and Primo. I then printed up a table I keep with my machine. I also suspect that the specification of your spindle can be used to map the output frequency to RPM.

Dial it in with a potentiometer

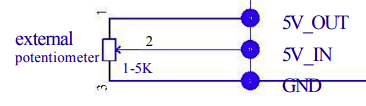

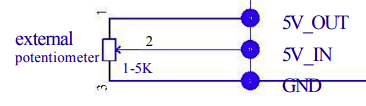

The next solution up in terms of simplicity is to add a 1K to 5K potentiometer. A tachometer will allow you to label the print dial markings mapping rotation of the pot to RPM. Hookup from the manual:

Set the RPM from the SKR Pro board

If you want to connect your VFD to your MPCNC you will be using the PWM output from the SKR Pro board. You are fortunate since this VFD has a 5V input. Most I’ve seen in the past use a 10V input. You will need to play some with the firmware settings to map the PWM values output to the g-code G0/G1 ‘S’ parameter spindle values. A few settings that stand out:

//#define SPINDLE_FEATURE

#define LASER_FEATURE

You probably need to commet out LASER_FEATURE, and uncomment SPINDLE_FEATURE

/**

* Speed / Power can be set ('M3 S') and displayed in terms of:

* - PWM255 (S0 - S255)

* - PERCENT (S0 - S100)

* - RPM (S0 - S50000) Best for use with a spindle

* - SERVO (S0 - S180)

*/

#define CUTTER_POWER_UNIT PWM255

You need to set CUTTER_POWER_UNIT to RPM

You will likely also need to adjust M3/M4 Power Equation to match your VFD/Spindle combo.

As for connection, V1 maintained firmware set a PWM pin in the top of the configuration.h file:

#define SPINDLE_LASER_PWM_PIN PC9

#define SPINDLE_LASER_ENA_PIN PB0 // Heater2

You will need to connect pin PC9 on the Skr Pro to the 5V in on the VFD, and you will need to connect the grounds together as well.

External display

The VFD has a pin that shares the frequency. You will need to figure out how that frequency maps to RPM by using a tachometer or other method. You can use that frequency output pin with a microprocessor and display to output the RPM. This is not a hard thing to build, but I’ll not add any details unless this is your selected solution.