Sorry, I am not understand what is too high? I upped the current slowly, running a job in between until the motors were warm, but well under 50c. This is how I came to 1.3 amp, but the x2 motor was still cool, so I kept increasing this one with no change. So, is 1.3amp too high? Since the 2amp setting didnt do anything, I will bring it back down. When I awapped drivers I did lower them to 1.3amps.

What do you mean by in motion. As suggested, i ran the motors for at least 20mins to test temperature.

If you are not connected you are not actually increasing the current, I don;t think. 2A would cause a driver thermal shutdown very quickly.

I asked a few questions in my last reply did you have a look at those?

OK, I am an idiot. Sorry for wasting your time with this. I had misinterpreted the instructions and left the jumpers on the E0 slot. I think I was a bit thrown off by the axis labeling table where it says “Z1-- leave jumpers in place.” Since this is after Z0 in the table, I left the jumpers in place. I realize now that there is another set of jumpers between the Z0 and Z1 near the motor connections. The TMC connection error is now gone, so thanks for helping me fix this. Should I reduce the 1.3amps, or is that OK? I have my system outside under cover and at 60F ambient the motors are running around 30C and at 80F, they are about 40C. I have only cut foam and air, so not sure if this will go up when there is more load on the tool. On the bright side, I learned a lot about operating the tool and working with the software.

No worries at all, if anything it is my fault for sparse instructions.

Reset to factory, I think there is an option for that. That puts it at 700-800 something like that. Then when you start longer cuts pay attention to the temps, and increase if you need to but I doubt you will. Skipped steps are actually extremly rare.

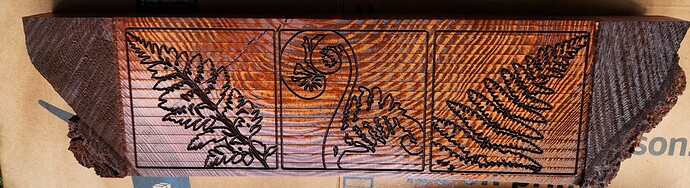

My first cuts in wood, well mdf anyway.

First cut is pretty ugly (bottom left). I had just run @jamiek square and ruler tools with a pen and it looked great. So I tightened the belts a little and upped the current to 1A. I noticed when I was putting the router in there was a little play. I used advice from another thread. The core clamp was tight, but the bearing was not touching. I loosened the other bearings, ended up removing them and reaming out the holes because they were pretty tight. Reassembled trying to use the slop to force the non-clamp bearings to engage. The bearing still freely rotates, but the slop is gone.

Second cut(upper left in first image), skipped steps on z after second pass. Turns out the roter was rotated a bit and interfering with the core, but the XY looks really good.

Third cut, success! Well, at least much better. Dimensions were slightly low, 98.6, 99.2, 99.4. Depth was spot on 12.02. Happy to finally be cutting something besides air and foam.

Nice work! What’s the first project on the drawing board?

Great idea, looks really nice. You might want to check the tramming though, you can clearly see the ridges the endmill left (or was it on purpose as a design element?).

Yes, definitely need to look at tramming, but I did not mind the effect on this design.

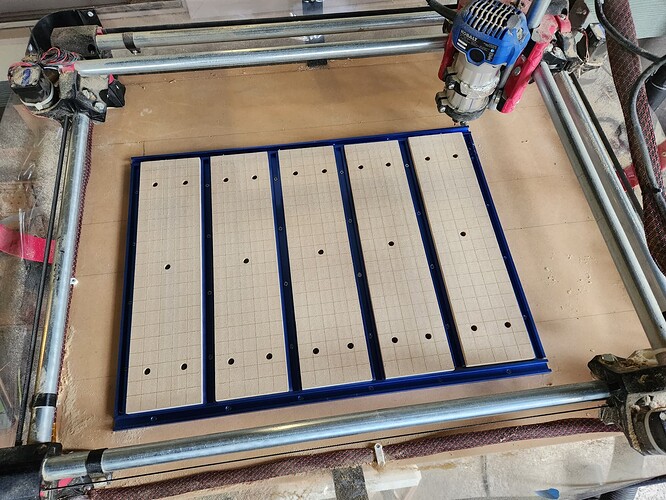

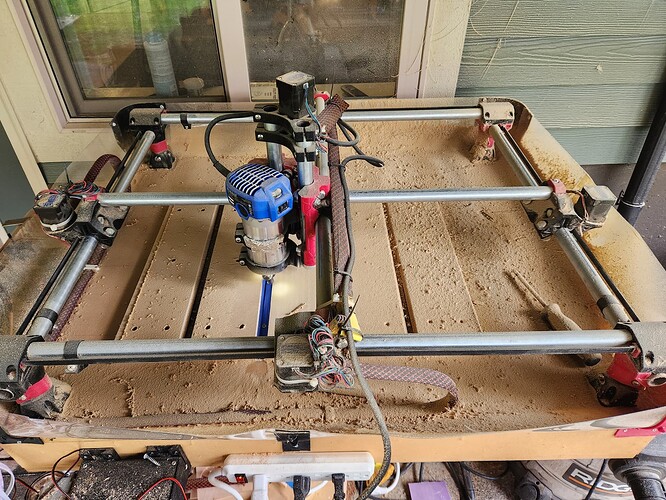

Might want to think about a dust collection. ![]()

I actually really like this setup. Maybe have a few spare pieces of Track around to use at the far edges for larger pieces, and this seems pretty sweet.

Getting the impression that you don’t appreciate cnc glitter… ![]()

Just had to get a new shop vac myself. Wore out the old one

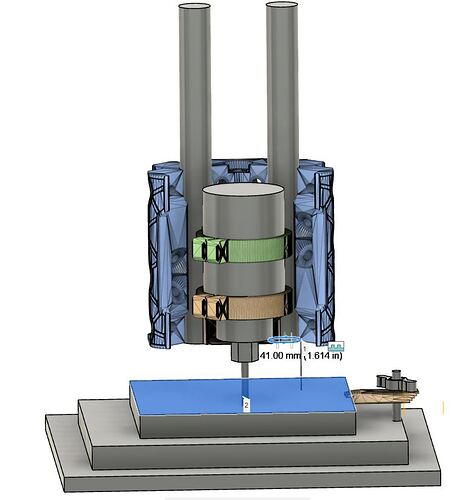

I have been struggling with z-clearance lately after I started using some new clamps. When I first built my MPCNC, using the calculator default of ~80mm seemed like a lot of clearance and I read a lot on the forum about not wanting to go too high with the legs due to stability. Recently I started looking at dust collection options and most of the versions I have seen have the tubes come under the core so that it does not give up any cutting area. The way my Primo is currently set up, this would not work for me unless I use really long bits and shallow cuts. I did a quick mock up to try to understand why I am challenged for Z- travel. This helped me see that the designed travel is to the table and after adding the spoilboard, a 3/4" board to cut, clamps that go above the board I am at 20-25mm of usable travel which is barely enough to cut through the 3/4" board.

I am looking for some help to first make sure I did not do something wrong with my setup and second understand how others are addressing this and if there are other solutions I am not thinking about. I can think of several ways to improve this, but I don’t like most of them:

- Cut a hole in my table to recess the spoilboard. This would add 19mm.

- Use clamps that don’t go above the surface of the board. I was using cam clamps with inserts before and they worked well, but took more time to set up, were sometimes came loose with vibration and often lifted the board up off the surface slightly. I have also screwed down the board and used painters tape and glue. I like the current clamps best so far, but there are always trade-offs.

- Lengthen the legs

Hopefully I am missing something easy here because none of these options are my favorite.

Put the legs on strips of MDF, this gives you the height you need, you can see it here for instance: MPCNC Primo Schneewittchen Reanimated - Oldenburg, Germany

I had built mine on top of an old dining table. To compensate for the thickness of the spoil board on top of the table, i replaced the leg tubes with ones cut 3/4" longer. This raised the whole machine up and worked beautifully.

If I were to add MDF strips, is it as easy as unscrewing the legs, adding the strips, and screwing the legs back in (making sure they are square)? Or will more disassembly be required?