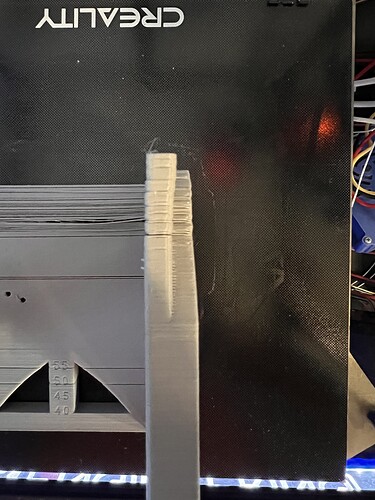

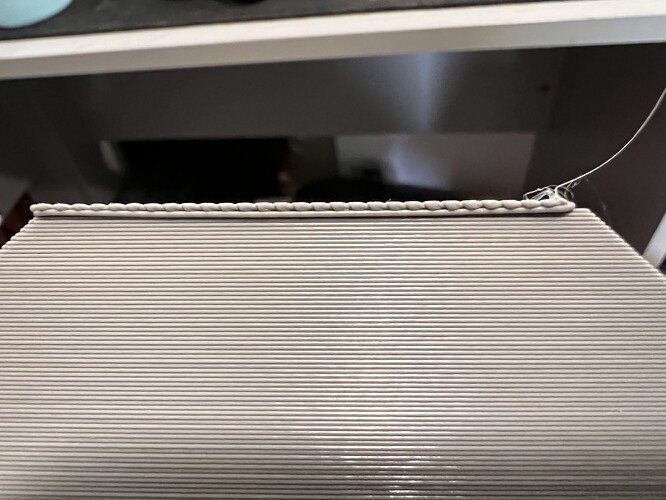

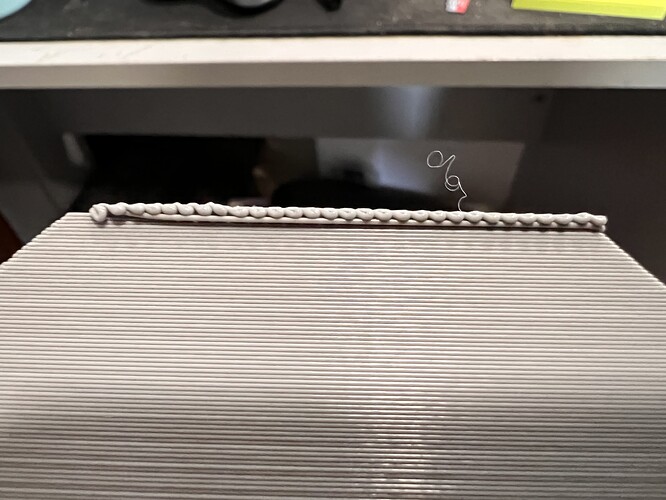

that looks to me like your extruder was starving and you didn’t get enough filament… did it get caught on something? or was the extruder skipping steps or slipping on the input? nozzle partially blocked? cheap filament? I’ve made way too many things that look like this.

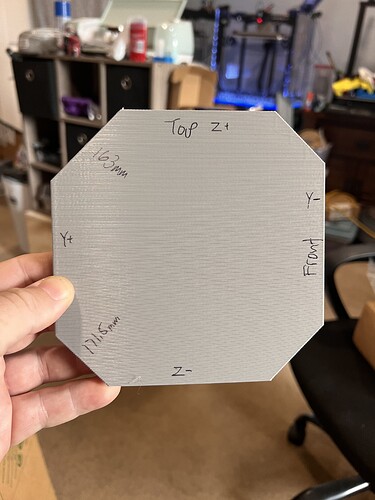

Taking another look at the photos, and I started thinking that the XY error does kind of look like a 45° thing… which would be one of the CoreXY motors, and yeah, one Z motor is dropping a bit more than it should.

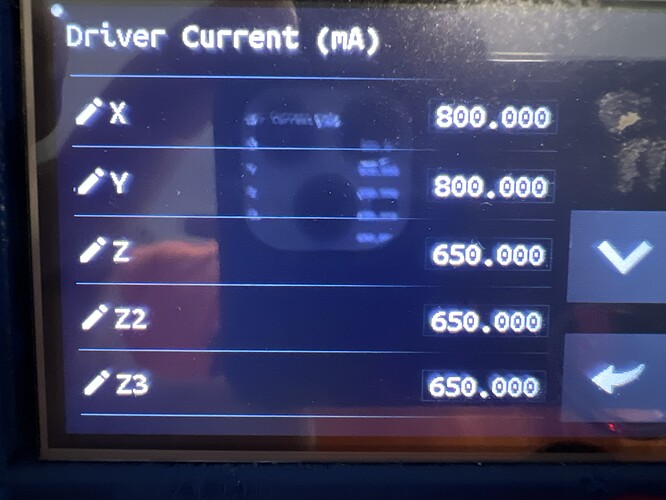

What do you have motor current set to, and … you did jumper the SKR to put the steppers into UART mode, right? ![]()

Anyway, get potential mechanicalbissues dealt with first… a motor skipping steps sounds pretty distinct. I can hear it when my printer does this (typically because the print has warped and lifted and the print head has hit it and got stuck) even when the printer is in the other room.

Its brand new Hatchbox PLA that was dried and put in a Dry box with a monitor that shows 10% humidity. It was and still is feeding just fine. I did my best with the pics but the start gaps are only on the back side. its a straight line there. on the other side its leaning like only the back Z motor skipped steps

To me it looks like it only moved in y. It’s hard to get a good pic of it

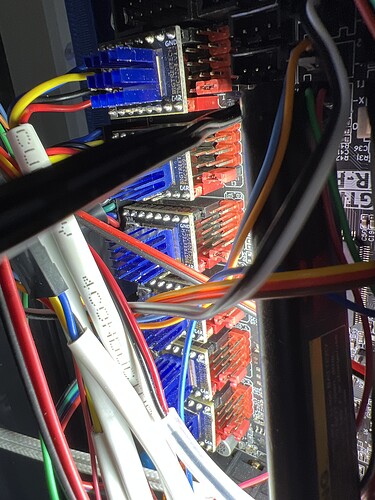

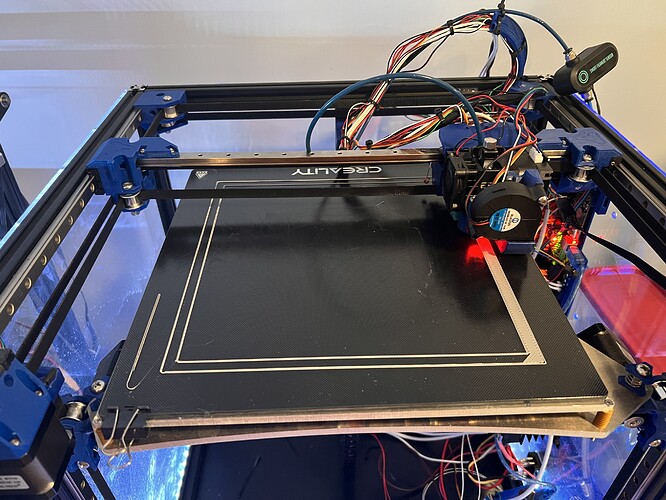

Ignore the messy wiring, its a work in progress…

One thing I have noticed is they seem to sound idk nosier maybe. I’ll try to get a video of it printing in a little bit and post.

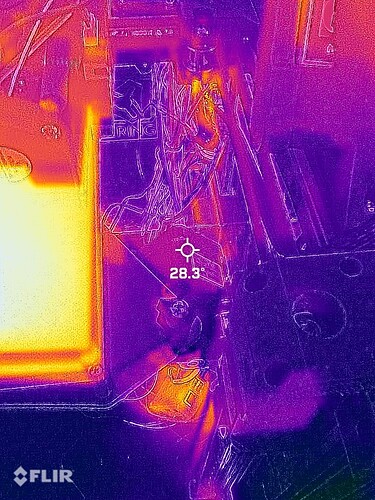

Looks like I might need to put a fan or something on those drivers.

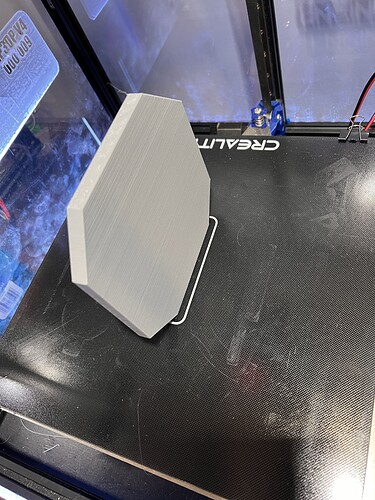

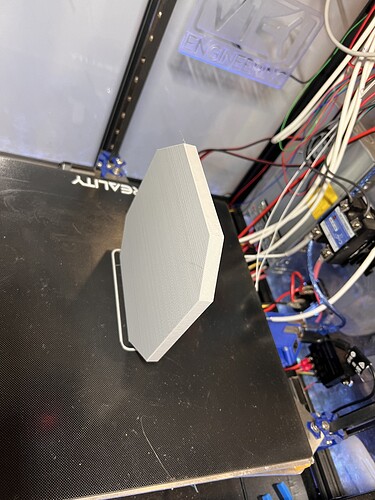

It’s printing again. But only a 2.5mm think square I made up in fusion so I can measure it. Come to think of it idk why I made it so thick. One layer would have been plenty lol

How big are your motors? Are they the 84 oz inch ones or the 56’s that have the removable connector on them?

I had lots of problems at first until one day I was looking at the size of the motors on my hypercube and the lightbulb went off. I ordered some 84’s and it has been rock solid ever since.

These are from @vicious1 I believe all he sells are the 84oz ones

@probrwr, are you running V1E/similar 84oz XY Steppers at 1amp or something else? Several month old Snapshot of your Klipper config has 1amp configured.

Think I started with 0.8 but then dropped current after seeing the stepper’s steady state temp (using the V1E temp stickers). Mine are at a measily 0.6 ( my Klipper config ) which probably too low.

@SupraGuy curious what current’s working for you?

What is a safe temp for the drivers? some of them were around 53°C after just 2-3 min of printing. If I bump the current wont that make them even hotter?

I do have 2 40mm noctua fans here that I was going to put in the new LR3 that aren’t needed now that its switched over to jackpot. I could try to come up with some kind of mount for them to blow over the drivers…

I will look to see what my current settings are. probably still at 1 but maybe not as that may have been when I was using the smaller ones.

Lol. Mine are juiced right up. 1250mA for XY and 900 for Z. I am running a Duet 3 6HC mainboard though, TMC5160 drivers, I think. Those drivers will dish out a LOT more current and not bat an eye. My motors stay reasonably cool, so I haven’t spent time tuning them.

A fan on the drivers will do wonders. I guess I dont worry too much about noise. I used to just have a 120mm fan pointed at the drivers before. I don’t have that now though, but the Duet doesn’t seem to need anything more than a vertical mount to let things cool by convection.

Well I have a print going now that SEEMS to be going good. No skipped steps so far at least. I did find one major deal (at least I think it is) in the slicer. Infill was set to 300% speed. And that’s where I watched it start skipping steps earlier tonight. I brought that down to 150% and its doing much better.

Another change I’m thinking about making is lowering the Acceleration down from 3000. This thing really jerks sometimes and I think that’s part of the cause of missed steps as well. This being a larger printer than Ryan builds I just don’t think it can quite handle as much. Or he may be running much different settings in his slicer… I’m not sure. I know as much as I thought I knew about 3d printing I still have a TON to learn LOL. Any tips or advice will always be welcomed!!

It may be a worthwhile pursuit to share slicer profiles for the MP3DP. Of course some details will be off but if we can see results and cross reference speeds, we might be able to get some data that will let us optimize our own printers. This is lime the kind of leverege that Prusa gets within the slicer to get high quality printing when you use their printers.

It’s still a bit different, since we tend to be tinkerers. If we built our printers identical.to Ryan’s with the same control boards, firmware, settings and hardware, we could all find the ideal settings for different layer heights, filament types etc, but I think we could get closer based on that most of us would be using an SKR Pro with 2209 drivers, running the V1 Marlin firmware.

Outliers might be using Klipper, or like myself, RepRap Firmware, and of course changing the footprint or build envelope will have an effect… I don’t mess with the slicer settings much, most of my print speeds are maybe slight tweaks on settings that were there from some other model, or default settings that the slicer came with. I know I can often run with the speed factor up to 125% on the interface, and not have real problems, so I know I’m leaving something on the table… but sometimes, I don’t get away with it. (110% is pretty safe for thin to moderate layers though.)

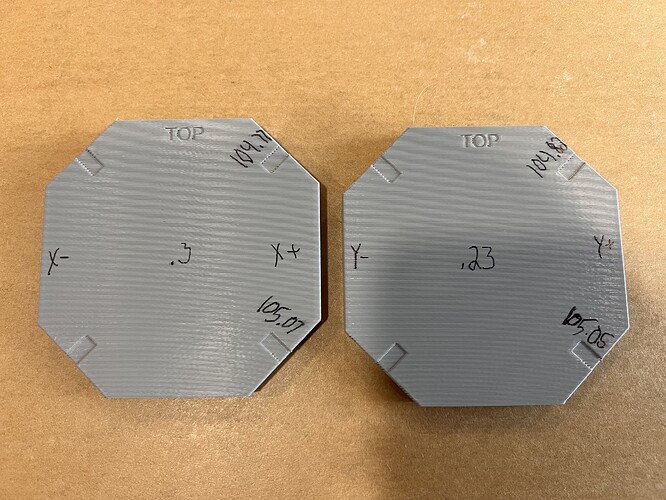

Well it finished the test. And the print looks good. But that’s where it stops. Its 8.5mm out of square… That’s measured with a tape measure as I made the model too large to fit my calipers over it. printing another now that I can measure that way, also printing it in the other orientation.

The one I’m printing now is in the opposite direction so we will see how far that one is out. Then to figure out how to fix this mess.

How do you know how much the motor hold torque rating is? Do you measure it or the stepper depth? I have some V1E steppers and some 6 pin steppers and some 4 pin ones… I was thinking the depth was of interest for this, but not sure. I’m seeing new z steppers in my future.

@orob please don’t take my build as anything negative toward MP3DP… This as all been my errors not anything on the design.

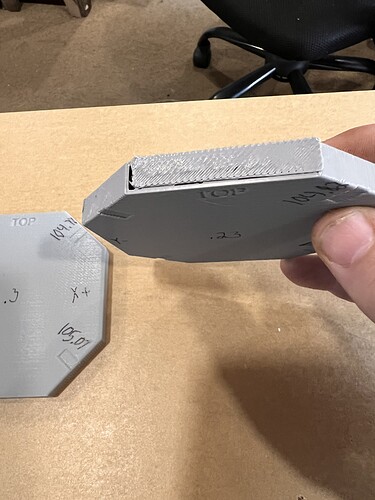

Ok both new parts have finished printing and for some reason are not near as far out of square as the first larger one. So that has me questioning some things. Also they both skipped steps at the same spot at the very top.

Just realized I’m an idiot yet again. If you take a close look the chamfers on the corners are not the same. That’s why it measured different. Couldn’t see the forest for the trees… Well that makes me feel a little better about it now. I know I set them all the same on the new smaller one. So now the question is how do I take that little bit of error out? or is that enough to even worry about?

this is all the risk we take when we DIY. I’m a tinkerer and a problem solver so, I appreciate the fact that you share the struggle so we all can learn in real time and not just post how smart you are after solving it. This is good info on what to watch for and then how to correct it. It is cool how people chime in and say, " I made an error here, try this." in an effort to spare you the time they spent figuring it out. It just speaks to the goodness in humanity. People helping people out because they can. I’m not done making all the mistakes yet, so when I mess this part up, you can help me out.

Thanks @orob this thread is definitely full of that!!

It IS proportional to the length of the motor body. The 6 pin ones are generally Unipolar but can be wired for bipolar operation. 4 pins are bipolar only. The V1E motors are 84oz in. the ones with the plug on the motor body are typically less.

I am using the smaller motors on my z axis and have no issues with them. I was having the same shifting problems higher up in prints like @Jonathjon was with the smaller motors on xy.