LOL I love it. Lord knows he will overthink it just like the rest of us LOL

I might need to modify my build then.

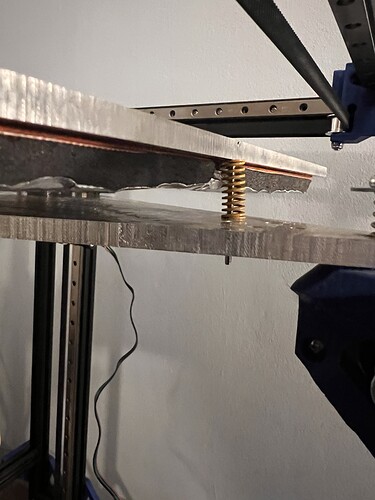

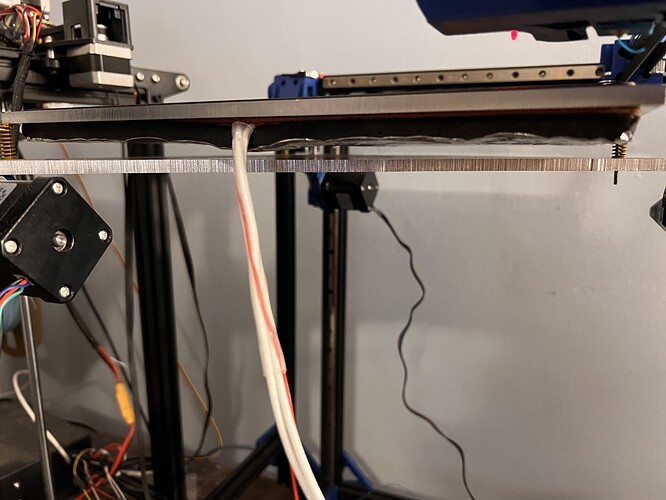

I used vacuum hose instead of springs between the aluminum plate and the MDF plate. The insulation touches, but nothing is compressed (maybe a touch). I tightened the M3 bolts just enough until the locknuts on the bottom touched the MDF “securely”. Kinda like how we snug up the locknuts on the MPCNC.

My bolts are long enough, that I could make the vacuum hose a little longer so the insulation is air-gapped from the MDF if you think it’d be worth it.

The holes in my aluminum plate are perfect size for the M3 bolts. The holes in the MDF are slightly larger.

Regarding the washers on the bed to Z mount… I had somehow printed two batches of the 3d printed washers, so I went nuts and put a washer above AND below the MDF plate on the Z mounts ![]()

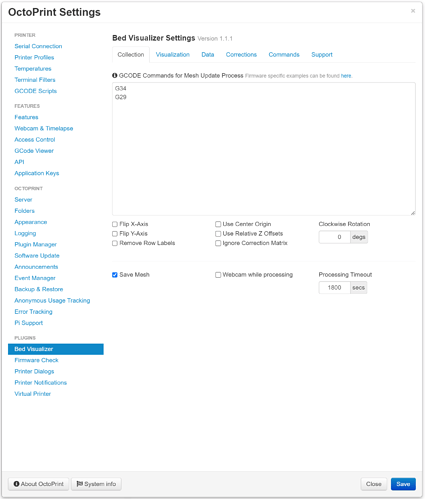

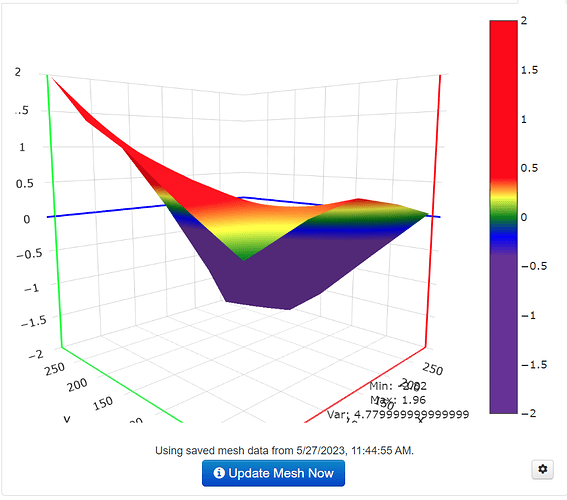

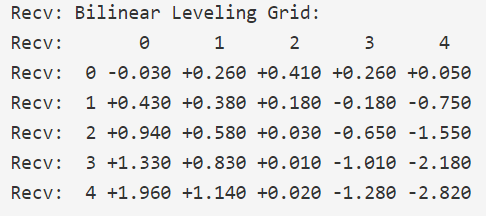

Just use a visualizer and see if your bed is bowed up. The problem is since we are using a Bed that lowers I think the graph is flipped? I can’t remember how that works. This case seems to point that direction.

If I use fasteners on the bed surface of the printed part I try to make sure it is not critical, and I do everything in my power to never ever mate to bed surfaces, or anything to a bed surface or within 5mm of it.

Oh. This could explain a lot while I was setting mine up.

I was tightening a corner and it didn’t seem to help. I should be loosening it…

The bed itself doesn’t bow. it just has a dip/raise in one corner.

As soon as one of mine frees up I can stick a penny on the bed and see what happens in the visualizer. I am 90% sure I already did this, I just don’t remember the outcome.

Yea, the graphs will be upside down because our bed moves. There should be a checkbox to invert it. “should”…

ahhh. Maybe that was just with the duet firmware. I haven’t touched octoprint in a few years.

I am no octoprint pro by any stretch of the word. @jeffeb3 this is where you come in LOL

I use transforms all the time in my software. So I know to never trust them. Test them (the penny is a good idea) if you want to really know the truth.

I think those flips are just for the visualization. From what I can tell, the bed moves the correct way to keep the bed level.

I assume so as well, but getting the display true to our geometry would help with issues like this one. What if the bed is actually sinking, not bowing up, that would be crazy.

They are, but you have to remember if it’s showing a corner going up, you have to move the rail up as well, because the bed is actually sinking in that area.

It also could be a crooked rail…

I forgot to do the penny test. I’m making a note.

That’s a good point. If the back rail isn’t horizontal to the rest of the max, it’d show up as a twisted bed.

Here it is, I knew I did it before, Building the "Repeat" printer - #378 by vicious1

So now we know on these it is + = a high spot.

So JJ’s printer has a low right back corner, a low right rail corner, or the wires are pulling the head up in the right back corner.

New longer M2.5x40 bolts were here when I got back in town. Installed them with 2 each of ryans springs and it still sat down on the insulation in the back. Front stayed up. So i ordered some yellow 20mm springs from amazon and just put them on. Now it stays up and level (ish) all the way across.

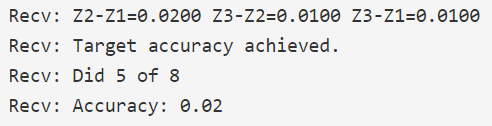

Here is the first G34 after the new yellow springs…

And here is the bed visualizer…

I’m starting to think only having 3 mounting points for the bed is a problem. The bed is completely free to move. Its basically just sitting on the springs right now. I didn’t even put nuts on it yet. Also all of the screen shots are with the bed cool. I can run again heated if need be.

Maybe the aluminium bed is bent?

According to a straight edge it isn’t… but I guess that doesn’t mean much. those 2 outer corners in the back are completely unsupported. only one bolt/spring in the middle there. I think that’s where I messed up when I made the support/bed. Ryan hadn’t put the instructions in the docs yet and I went in blind. I have a feeling I’m going to end up having to scrap this support/bed and start over.