Very exciting to see it coming together!

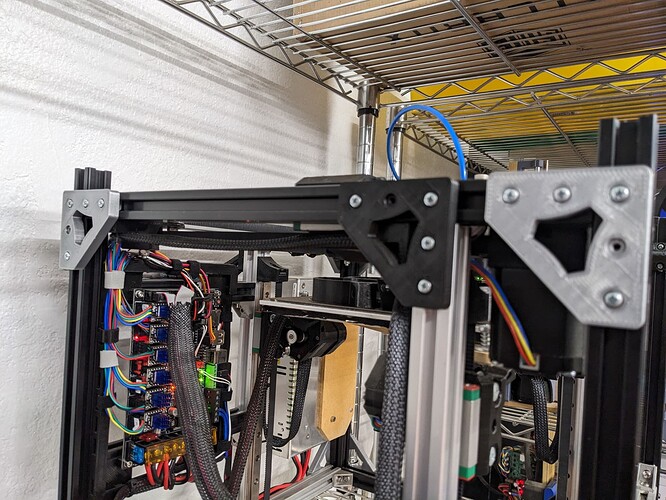

I really like that electronics case. It looks like fun. The wiring is awesome. I always dream of my projects looking that nice. They never do.

I don’t really like the right angle brackets. At least, there seem to be too many. But in the effort of fewer part counts, I can see why you used them. I would rather something red with some curves there. At least you know it won’t rack with this things installed.

I also really like the look from the front. Nothing in your way when watching it print. ![]()

First layer torture test!

I hate them. I keep thinking of ways to make a better box. I am really surprised how much wood moves over the relatively mild seasons I have here in Cali. The next printer, I might try another plastic or metal frame. It just needs to be extremely adjustable. I am confident after building these things that no off the shelf printer is this accurate without extreme tuning…if it is possible.

With that said…I did consider removing the corners. They are not really needed. I could make it work without them. I just got nervous about it and decided against it. That would remove a considerable amount of extrusion and brackets.

Thank you! I take my time with it, and enjoy it to some degree. Or maybe I just hate looking at rats nests. There is plenty of room to hide wires, but Somehow this worked out not need the behind the board storage.

What is the current size of the hotbed?

That is as designed, 200x200.

I would probably remove the ones holding up the controller and maybe the Z axis supports. They don’t look so bad on the corners. But they are weird in the middle.

I have some corner brackets like this. I have two kinds. Mine came from a kit with 10m of 2020. The black ones were a little longer and have extra tabs. But they interfered in two places, so I also bought the more standard sized silver ones from amazon:

https://www.amazon.com/gp/aw/d/B07GGLYX9V?psc=1&ref=ppx_pop_mob_b_asin_title

I bet you could get away with those for the middle pieces. On the outermost corners, you probably still need plates. An arc like your 120 logo would be great. Except it needs to be 90 ![]() . Even two plates per side is probably enough racking prevention. I wonder if you could quickly cut them from ACM. Mine are 3D printed.

. Even two plates per side is probably enough racking prevention. I wonder if you could quickly cut them from ACM. Mine are 3D printed.

I had the little brackets you linked. I used them all on the last build. I will be getting more for sure.

I do have some 3D printed ones big ones , with a logo!

Those have a lot more character.

I don’t want to focus too much on those brackets. The entire build looks great. This is just one small piece.

All good, I needed the confirmation. I am going to try to bring this one to Rmmrf, I figure these brackets would survive the trip the best.

I like those V1 logo printed corner brackets. Are they released anywhere?

They are in the CAD for the mp3dp v4, I can break them out if you would like. Fits an M3x10mm screw.

Love the case and overall look. Getting hard to resist building these

ACM would be cool. What cheap material could replace the chonky angle brackets? Could fully enclosing panels of milled 3mm acrylic/polycarbonate, or HVAC sheet metal work, sealed MDF, sealed plywood, Corian, or something else?

Would you trust accuracy of hole drilled panels, or should they have sloted holes bored out to allow micro-adjustments when assembling?

Fully enclosed printer would give me piece of mind that no one’s curious fingers are going to end up in multiple pieces if this thing is going full speed while on display. Plus less warp and energy consumption.

I love it!

ACM would be cool.

I love that stuff. I think the only problem with using other materials for a frame is it will take a lot of whatever. 6 panels at least. It will end up looking a lot like an ultimaker, those do look nice though.

I think I could whip one up…Dam this is tempting.

ACM equals enclosure?

ACM/dibond is the aluminum plastic aluminum panels. They are really nice looking and a good balance between all plastic and all aluminum. Sign shops use them a lot so if you can find them locally they can be cheap.

You could make a fully enclosed printer if you wanted, For me printing PLA mostly, that is not a goal but I would also not prevent it.

I also print PLA mostly so not sure if I need an enclosure. I have TPU and PETG still in the original boxes.

Why do you prefer PLA over PETG?

I think if you are going to have a selection, Pla, ASA, and TPU cover 99.99% of anything you could need.

pla for rigidity, asa for heat resistance, tpu for soft stuff.

Makes sense.

I did find dibond here and it´s not that expensive.

Do you have an intended printing speed for pla for v4?