cheers, same still sorting out the tech side of it took few goes to get it to connect and the move panel to be not faded out , all connected now and can jog etc, ive been using light burn for couple yrs with laser, so am liking how its very similar as jumping between different programs can get confusing for me with my head injury, havent done any cutting yet just air tests

re not wanting to home z have you tried playing around in the move tab /position ,turn on workpiece tab than setting z height /click go to z, than zero workpiece z ,

hope that makes sense

For non commercial users:

Fusion 360 - free, more features

Kiri:moto - free, more features

Estlcam - free (with nag screen) or 60USD, no design but more features - 3D carving & Trochoidal milling supported.

In its present form I don’t see a really compelling reason to buy it - I don’t need the design bits as I’ve already got lightburn. IF it had 3d carving, trochoidal and inlays worked then maybe, but that’s where the sticker price issue lands, it’s a bit much for a ‘nice to have’. Maybe if I didn’t already have light burn the design tools would be more tempting.

Currently we ONLY support G54. When I went back and looked at most of the other “accessible” cam out there that was focused on routers that was the case, so we went with it.

LB currently outputs that header code by default and it is not user editable. I can see a good argument for all of that to be included in the user defined Start G-Code so that you can make it look how you want. I’m going to go back to the team on that one ![]()

Thank you for that run down. Hugely valuable.

We are planning an SD upload in the future. With grblHAL, fluid and RRF all supporting it it makes sense. We already have a couple devices doing it in LB. The biggest thing is we would like to be able to kick off, monitor and stop the job in MM so we are looking into that. Not all of the firmware’s have the nice webUI fluid has.

Finish passes are in the road map, currently I handle them the same way.

I think you are both not completely right and wrong in those run downs. All of those software’s have features we don’t and we have feature’s they don’t. I know because I used them all found gaps and made sure we filled them where we could.

Fusion - we have rapids and tool changes and don’t cost 700$ a year to use them (I’m a paid fusion lover. It’s the best cam out there under 1000$ a year hands down)

Kiri:Moto - We have ramped and helical entries and just significantly more control over the operation types we have. Sure we don’t do mesh or 4th but its in the road map (Ok kiri:moto has some neat updates since I looked at it. It does have helix’s now. )

EstlCAM - no 3D, but I’m already testing our trochoidal feature.

Overall though yea, if you need meshcam type operations MillMage probably isn’t your tool.

Try out inlays again if you don’t mind. I went back and messed around with the issues you were looking at and I think there may be some confusion on how the inlay tool works. Male is only a profile. When the dev working on it made it he intended it to cut all the way through the material and not just be a clearing operation. We are looking at reworking it to add and option for pocket clearing. But it does handle islands, I just think it works different than you expected which is completely fair because I expected the same when I was using it.

I was one of the Knee Jerks. I was expecting less, but like I said above, I have a project I need to do when I get back from work. I am going to work it 100% in millmage. I will see what happens.

I do appreciate being given that opportunity.

When released, will you offer the temporary free start like the lightburn? maybe it will convince those on the fence.

Also, Is there a document on start to finish, even if it is rough?

I have used lightburn, (purchased edition) but not alot. So that is why i was asking.

Admittedly, coordinate systems are not something I use a lot and I’m sure there are multiple ways to use them, but I don’t think I understand what you mean by that. It makes sense to only allow 1 coordinate system per project, but it shouldn’t matter what coordinate system is used. Estlcam doesn’t do anything with coordinate systems either but it also doesn’t set it to G54 (unless I add custom start gcode).

For FluidNC (and I think GRBL), G54 is the default and it sounds like it’s reasonable to set it to G54. I would just prefer it not be specified at all or at least let me override it via custom gcode. When I run a job, I’m doing it from a gcode file off the SD card. Before running a gcode file, I home the machine and move it to the XY position I want to start at. The gcode script zeros X and Y. It handles setting Z via probing. If I wanted to change the coordinate system, I would do that before running the gcode script so I don’t want it to override it.

So, for example, say I have G55 set up so 0,0 is the bottom left corner of a fixture. I would home the machine, change to G55, move to 0,0 and start the gcode.

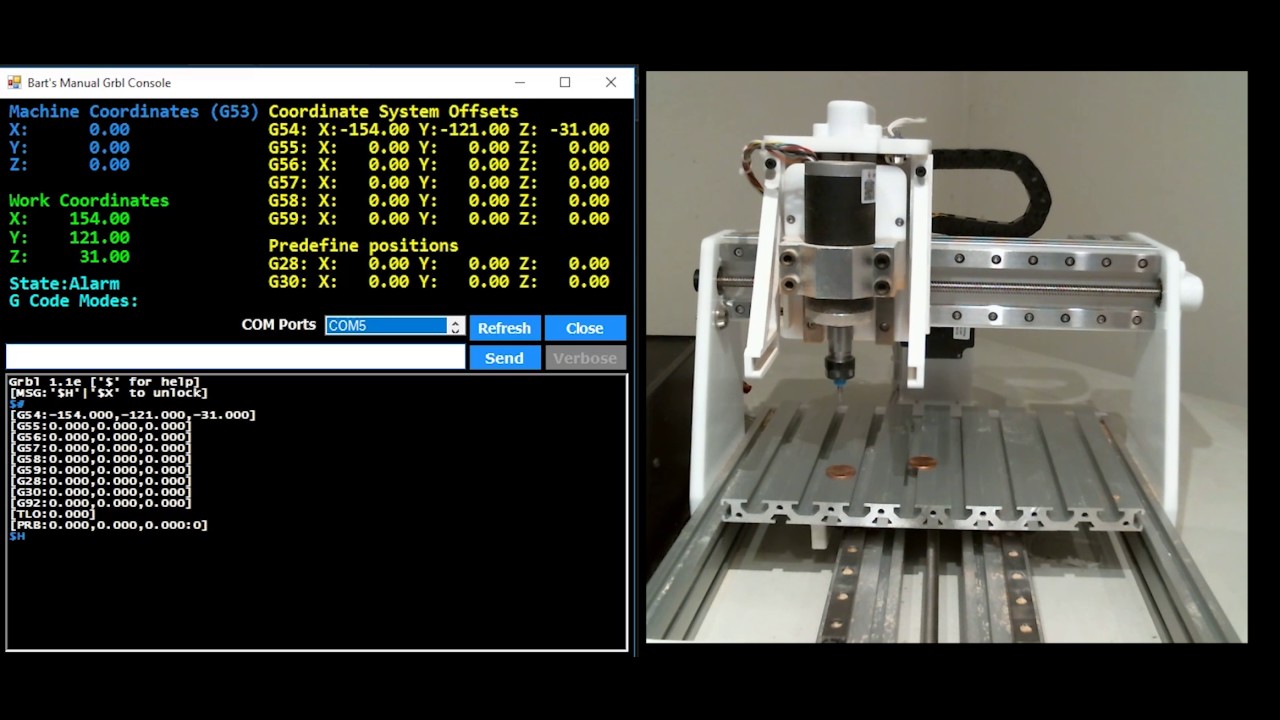

Side note: Much of my understanding of coordinate systems is based on this video from Bart of FluidNC:

That’s certainly feasible for FluidNC. The monitoring side is fairly limited. You get the percentage of the file completed. However, if you include line numbers in the gcode (and they are enabled in the config), you can get much more precise monitoring since it reports the current line number. What current means is a little blurry due to the way the planner buffer works but it’s fine for monitoring. I don’t use it, but there is a tablet extension for FluidNC that shows the gcode preview and can show the current position on the preview if line numbers are used. Gcode senders can do that without line numbers.

It would be neat if you could sync the preview in Millmage based on the current line of the job. Then being able to slide that bar around to see what it’s doing next could be quite useful. It would be really nice if it could provide info on when tool changes occur.

Just wanted to add that I really appreciate you dropping in here and responding!

What will be the price for us in new zealand , as cant find pricing

for me if i have pay same price as lightburn im ok with that.

my reason being have head injury due to an accident

so having to learn and navigate different systems can and has been very difficult for me.

only downloaded millmage 3 days ago and finding it pretty easy to navigate and feeling confident in actually cutting something with it , where other programs have done my head

have you considered doing a joint subscription discounted price for those of us that would use both lightburn and millmage, everyone loves a bit of discount

I brought a laser after my accident as could no longer run my business and had to shut it down so had find something to keep me semi sane.and hopefully create some income than through word of mouth people asked if i could do bigger stuff, hence the cnc path , still green as hell to the whole thing.

currently i have a Huge job underway where it all needs to be scaled down 1st cut with laser all pieced together taken to customer for approval etc before doing full scale with cnc eg: full size of one finished piece will be 3.6m wide x 3,8m high

being able to have the file in lb than transfer to MM will just save time and stress for me as both interfaces so similar

i hummed and harred over purchasing LB originally due to price only cause wasnt working and money was tight, but after purchasing it , it was money well spent even as a newbie / hobbyist

i guess everyone’s different how they look at what they pay for.

ive taking a gamble and thrown over 5 grand at a laser and the lowrider due to exchange rates lowrider 4 was $1800nz just for parts, than a 3d printer etc not knowing if i could even do it, or if it would even evenuiate to an income

ive nearly binned the whole thing many times due to struggling with software etc but now feeling more confident after only playing with MM for 3 days

so to me MM is a tool and will be money well spent. the right tool makes life easy

Estlcam can do 3D… Just import an STL…

I took that to be ‘yes millmage has no 3D’.

I’ll have another look at how inlay works. Anyone else find the wood grain effect in the preview window makes it difficult to see? I don’t know if there’s an option to change the grain effect for a flat color somewhere.

I thought that too. There is a dropdown in the bottom left of the preview window with a few options.

I think he was meaning that MM cant do 3d

I have been using MM in the beta for a while now. For any kind of flat sheet operations (which is 90% what I do) its awesome! So easy to load in multiple parts and lay it out how you want it. For Estlcam that is a massive pain for me.

Its rare I do anything 3d or vcarve so that hasn’t mattered much to me. When I do need that I just go back to estlacm.

I just installed the latest update so I will see how that goes in the next few days.

I installed it but was too stupid to load a dxf as of now. ![]() Will try again with more than two minutes…

Will try again with more than two minutes…

4th from the left next to save is import. That’s how I do it. If you go to open you have to change the file type at the bottom, its only looking for lightburn or Milmage files when you first open. I don’t remember having to change that on the import button

Have you downloaded MM RC2? They have made a lot of changes since Beta-15.

When I opened it this morning it prompted for an update and I did that one. Do I need to go somewhere else to download the MM RC2?

Mine says its 0.8.00-Beta-15

Edit: found RC2 and installing it now

Yes, here’s the link: Home - MillMage Documentation

Thanks for the heads up @Britt!

Wow thanks 4 that link!

have you had any issues with tool changes freezing ? , they are aware of this issue happening, 2 days ago tool changes working sweet yesterday they started freezing on me

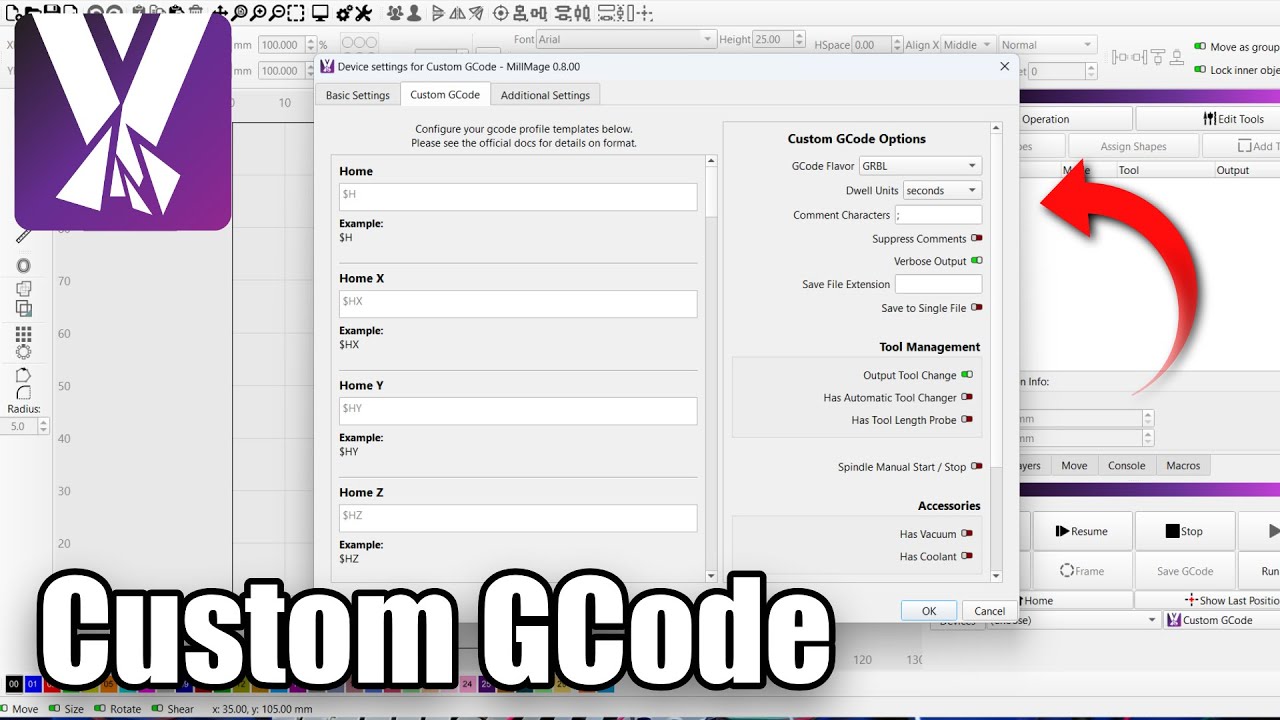

just came across this video in one of their posts

at the 3.10m mark he puts

@P for the pause command not M0

does fluid nc understand @ commands