Okay, before taking it apart again i want to write aa short summary about my LR4 build. I decieded to build a CNC at the beginning of december and started printing with every PLA I had laying around hence the name

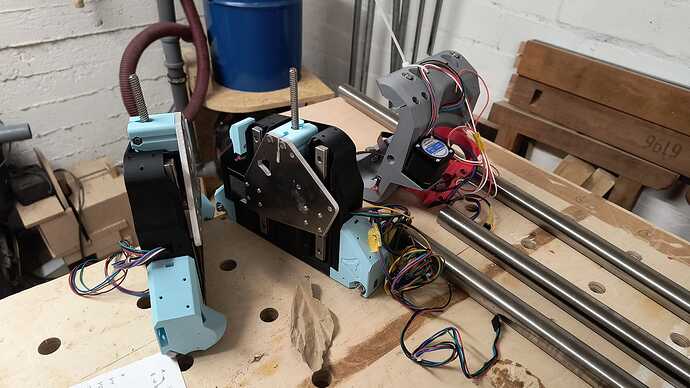

A friend hat to print the big parts, because my A1 mini only supports up to 180mm² after i got those parts on the 22n of dezember I started building.

Not much progress between the 24th and 1st. But after that i got around and finished everything

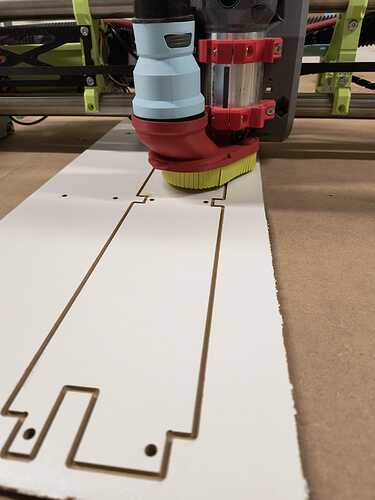

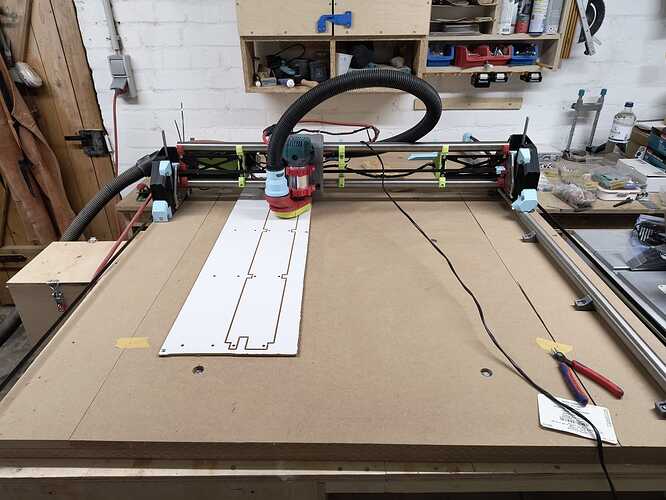

After building a Base for it out of 2 sheets of 18mm MDF I got everything mounted and my first movement. I got it squared to the best of my abilities and went into Gcode generation. After sorting some things out with my Gcode and getting really frustrated with Fusion360 I found out that the Lowrider is not really supported in the free version. So i switched to EstlCAM and got my first result. No crown, straight to 12mm MDF

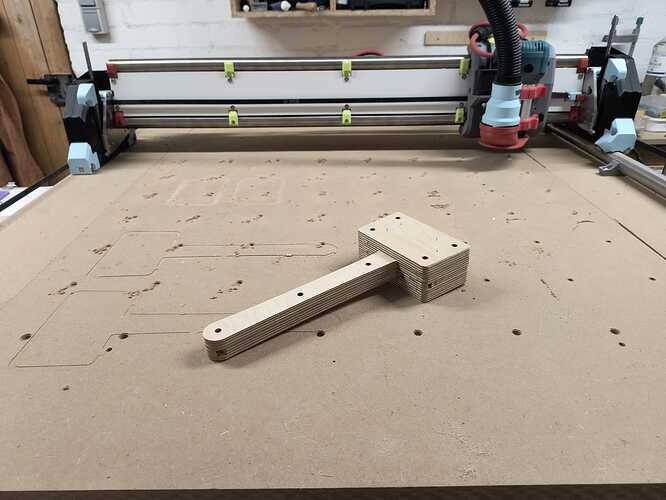

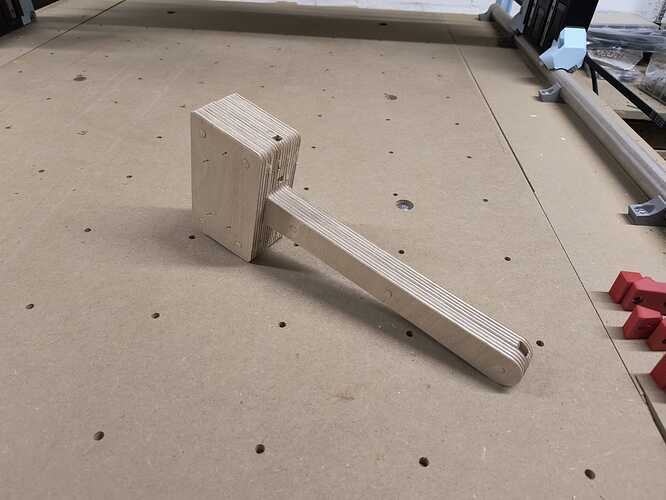

Next stop Strut plates. After cutting the first two 4cm short i realized, that I built the Machine bigger than anticipated because I went with 1000mm and 1500mm stainless steel tubing. But the 2nd pair looks like it is gonna fit. I will find out in the next days.

1/8” 2 Flute Downcut, 1440mm/min Feedrate, 3mm DOC, Setting 3 on my Katsu. After installing the strutplates, what would be the next thing to increase to find the limits? DOC or Feedrate?

Also if anyone in nothern Germany needs a pair of strut plates:-D

Al in all I spend about 10-12 hours from first screw to first cut I would say. Next up is installing the strut plates, leveling Z and then source some affordable 18mm plywood in germany to build a workbench. Birchply (Multiplex) is >60€/m²…:-/

Some things about the build:

The instructions are very good vor the most part. When installing the steppers it would have been nice to know that you should route the Z-Stepper cable first bevor it says you need to route the Endstops and y-Steppers

Tablesize, is stated in the calculator, but onmly the outer dimensions, it would be nice if the inner dimensions would be stated or how wide the runners on the side should be at least

And lastly i think it is never explicitly stated that the ymin and ymax assemblys are identicaal and need to be built paralle. I figured that out after beeing half way through my first part.