Spent some quality time with the LR4 today, currently taking a late lunch break from it and figured I’d update my build thread with some more nuggets of experience gained! This is so great for remembering the lessons I learn, and I’m sure others can pick up a thing or two along the way  In no particular order, but numbered for easy conversation:

In no particular order, but numbered for easy conversation:

Dust Collection:

I got the HF HEPA dust collector about a month or so ago and I am in love with this thing y’all. It is loud, but slightly quieter than a typical shop vac.. but the feature list is nuts: 17 ft anti static hose lets you keep it in one spot but connect it to whatever tool you wanna use (including the attachments it comes with), you can plug a tool into it and it’ll auto-on when the tool comes on and it’ll run for 10 seconds after the tool turns off. It feels like it has twice the suction strength of my Dyson DC23 which is a big boi canister model that kicks major ass (the Herc is a touch quieter than the Dyson). Not sure if I shared this info before and too lazy to check, so here it is again if so lol.

I had been using a 2.5" vac hose but dropped it down to 1.25" under the assumption it would give me even more suction power, while being much lighter and maneuverable compared to the big hose. It worked “fine” for a little while, but while surfacing (see below), the hose kept getting clogged from OSB chunks. I swapped it back to the 2.5" and it’s working like a dream again. Will use the small hose as an extension for my little portable Ryobi shop vac.

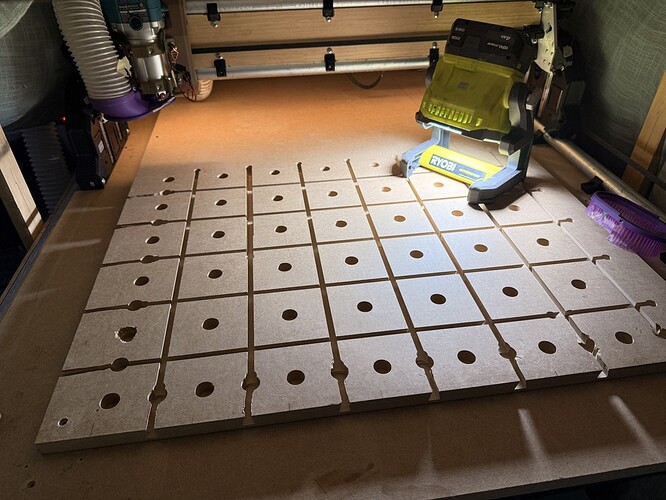

First time spoil board surfacing:

Shame on me for putting it off for so long, but I was having too much fun ignoring how uneven my table was  Turns out my OSB table top had a bow to it because I didn’t have any screws holding it down in the middle

Turns out my OSB table top had a bow to it because I didn’t have any screws holding it down in the middle  . Just a learning moment! Screwed it into the “studs” or ribs of my table with 8 screws, very nice

. Just a learning moment! Screwed it into the “studs” or ribs of my table with 8 screws, very nice

Then I decided to use VCarve to make my spoil board pattern, first time using it for real. I probably wasted an hour trying to get its GCode to do what I wanted it to do.. eventually I wised up and just used good ol EstlCAM! Running it in Parallels on Mac works a lot better than via WINE, though WINE certainly gets the job done (and it’s free).

I bought a 2" surfacing bit on a whim (cheapo on amazon), but I was afraid to use it after seeing a post from Ryan somewhere saying those bits are much too big and that results will be poor, plus it’s a big heavy sharp thing whipping around, so it didn’t seem safe. Instead I’m surfacing with my biggest bit, a 6mm 2 flute upcut: 100 mm/s, 2 mm DOC (surfacing in 1 path), linear @ 60% step over. I started at 50 mm/s, but after a few passes I figured I’d pump those numbers up because I was getting dust. Going at 100 mm/s now and it’s going great (I hit pause to walk away for lunch). I’m sure I could go faster and much more efficiently, but this is working and is almost done haha. Will get a nicer surfacing bit for next time, running this in ~10 minutes would be a lot better than the ~30-40 mins that I have now.

I’ve also finally seen the light on single flute bits being the GOATs. All those 2 flutes look really pretty, but the math says we can’t really go fast enough to get proper chip size from them… but if you cut the number of flutes in half, down to 1, you cut your speed requirements in half. I still have a baggie full of 2 flute bits from amazon (and QTY4 3mm singles from v1e  ) that are all basically brand new, so I might as well use them… but I’m wondering what applications a 2 flute bit is good for, in our machines? Wondering if there is a good use case for them, if so, then I’ll keep them new and sharp for those circumstances lol.

) that are all basically brand new, so I might as well use them… but I’m wondering what applications a 2 flute bit is good for, in our machines? Wondering if there is a good use case for them, if so, then I’ll keep them new and sharp for those circumstances lol.

![]()