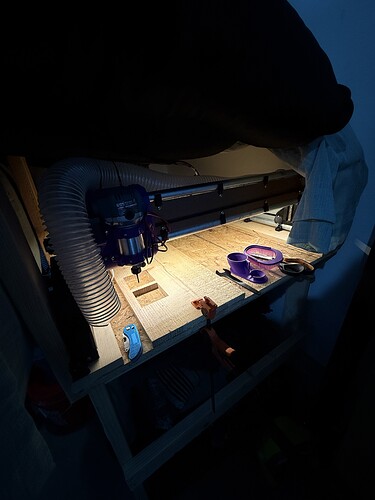

TL;DR: Totally new to 3D printing, CAD, and CNC. Strong background in geology and computer science (remote sensing) and I’m an avid DIYer (car maintenance etc). Decided to jump into the LR4. Every day is a new challenge. It’s a pain in the ass learning 3 new hobbies at once, but in the best way ![]()

Long winded intro post because everyone IRL is sick of me talking about “my CNC machine”:

Hey all, back in May/June I became obsessed with the idea of a CNC machine. A buddy started going to woodworking classes and they had a CNC machine, so he was telling me all about it and I was hooked right away! He made me a telecaster guitar body and ever since I’ve been obsessed with the idea of making every dream guitar out there, like to be able to have an exact replica of a Gibson SG for like $100 in material… and to be able to say you made it yourself?? Priceless.

To me this Lowrider CNC is a way out. A way out of financial anxiety; why buy what you can make? A way out of the mundane/a creative outlet; It’s like DIY on the computer, my two favorite things! I find myself spending hours every night reading about CNC, messing with the build, or learning CAD… it’s certainly a high challenge, high reward type of hobby, but that’s exactly what this ADHD brain craves!!

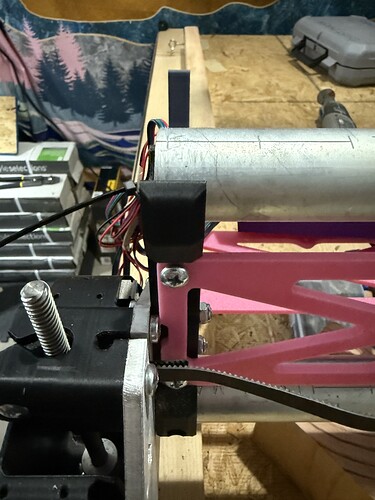

So I justified buying my first 3D printer because it was gonna build me a CNC machine, and my wife is cool as hell for going with it lol. I mistakenly printed all of my LR4 with supports, and then foolishly spent soooooo much time trying to rip out all the supports. Fast forward a couple months to now, and I’m still setting this thing up because I goofed up bad… I thought I was all done building and could finally cut stuff! But the circles I cut looked like ovals. Spent a whole day tweaking things and it kept getting better, but still ovals. Realized it was my strut plates, which were also cut poorly in retrospect.

What-had-happened-was I 2D printed (lol) the instructions so I could better focus on them and take notes in the margins (ADHD represent), but my dumbass didn’t check if I had printed the entire thing, so I didn’t do anyyy of the calibration or squaring ![]() .

.

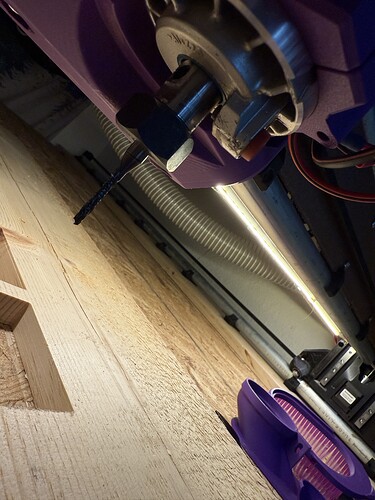

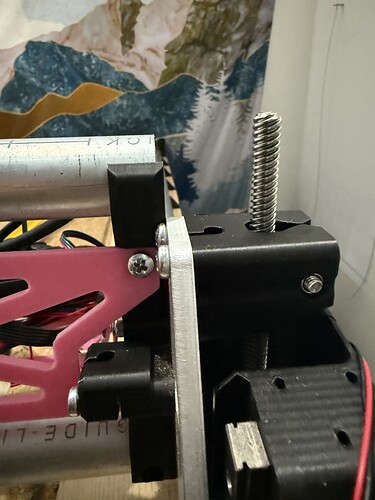

I printed new temp struts and got ‘er situated, but then I tried to home Z before the squaring test, and it basically blew right past the limit switches so I cut the power… turns out the Z1 switch is broken (thank god for those little lights on the jackpot). I traced the wire and redid my janky wire work but no dice. No big deal I thought, I already have a 10 pack of micro switches because I broke one during assembly lol… but no friggin clue where they are!! So I’m channeling my daily CNC energy into my build/intro thread ![]()

Many thanks to everyone for all the help and thoughtful words not just in my first thread asking for help, but in all of these threads- this community is special and I’m thankful to be a part of it! Now on to the cool stuff…