Heh, I did 5 perimeters with 5 top and bottom layers with my petg prints. Also using a .5 nozzle. .3mm layer height, 40% adaptive cubic infill.

Hey Ryan, quick question since it’s relevant to this discussion.

Are there models for control board boxes/screen boxes to print?

Awesome! Thanks for that, I didn’t even think to check through the profile on printables

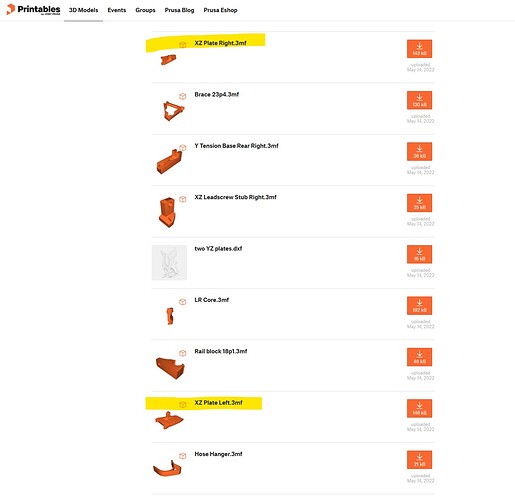

I am trying to keep all the models in a collection. Printables

Thank you!

Couple questions and thoughts about the LR3 table width and length requirements.

Obviously, I’d like to keep using my existing LR2 table if at all possible, and at the same time, I’d like to keep my current LR2 capability to “machine” up to and beyond 49"x97" sheet goods. I think it may be possible, but only with some careful considerations.

My existing table & steel tubes:

TABLE WIDTH . . . . . . . . . . . . . . . . . . . . . . INCHES . . . . . . . . . MM

Including metal struts on sides = . . . . . . 58.31" . . . . . . . . . 1,481 mm

TABLE LENGTH . . . . . . . . . . . . . . . . . . . . INCHES . . . . . . . . . MM

Not including metal struts on sides = . . 108" . . . . . . . . . . . . 2,743.2 mm

Including metal struts on the sides = . . .113.75" . . . . . . . . . 2,889.25 mm (call it 2,890)

X AXIS TUBE LENGTH . . . . . . . . . . . . . . . INCHES . . . . . . . . . MM

stainless steel tubes (X axis) = . . . . . . . 61" . . . . . . . . . . . . . 1,550 mm

According to the LR3 calculator…

…if I want a Usable Cutting Area of:

48 inches X

96 inches Y

… then my current table is too narrow by 2.19" or 55.7 mm. I could perhaps overcome this by re-adding wooden rails back on, between the table and the metal struts.

If the longer metal struts on the table sides cannot count toward the length, my table is not long enough by 3". If the struts on the sides CAN count for the length, my table is more than long enough by 2.75".

…conversely if I want a Usable Cutting Area of:

49 inches X

97 inches Y

…then my current table is too narrow by 3.19" or 81.0 mm. I could perhaps overcome this by re-adding wooden rails back on, between the table and the metal struts.

If the metal struts on the sides cannot count toward the length, my table is not long enough by 4". If the struts on the sides can indeed count toward the length, my table is more than long enough by 1.75".

QUESTIONS:

Do the LR3 wheels ride close enough to the edge to ride on the metal struts if the struts are the outside edge of my table, and assuming the width of the tubes and Strut Plate are right?

It looks like the only thing “requiring” the roller assemblies to be “inward” quite a bit from the table edge is having the Y axis belts “on” the table as opposed to being suspended out away from the table’s sides. Couldn’t I remix the Y axis belt mounts to have them hold the belt outside the table top, and gain some extra width on the machine’s X axis?

What I did was to add “wings” on top of the side rails of my table. I’m not the only one to adapt this way from the beta team. I got a couple of strips that I added to the edges, which was plenty enough to allow my machine to actually expand it’s capability in the X dimension easily enough. 2X4 rails added flat will be more than enough to accomplish this. I would probably not use the metal ones, but bolting in the Y rail to metal would be very secure, at least.

Instead of a remix of the belt holders, probably a simple bracket to hold them a bit off of the edge would be enough to have the wheels roll on the metal strut. That might be enough to make up the 3.2" of X that you need, if you put the screws holding the Y rail into your metal strut. This will preclude the ability to put your table against the wall (A nice to have feature of the LR3) but should be doable.

@SupraGuy Thanks! Do you happen to have pics of your beta build “wings” already posted?

EDIT: I’m looking now at your lengthy LR3 “PLOG”

That and the next post have some pictures of the table, but I didn’t really detail how I attached them.

I made them much wider than they needed to be, they’re 6" and 10" wide, I think. You can see that there is a lot of extra room there.

Thanks!

Does anyone have a nice STL file for printing the XZ Plate?

I see the XZ Plate.dxf file for CNC cutting, however it seems to have “some” circles for pocketing (?), and “some” circles for holes, and there are not clear specs on the pocket depth(s), if that’s what the outer circles are for.

I noticed (in the docs) some points about different thicknesses (seemingly within the same part), and so I think an STL file for printing could easily accommodate that. For instance it mentioned 9.5mm thick for M5 screws, yet also mentioned 6.35mm to 7mm thick for M3 screws.

If no one has an STL, maybe I could create one, if I can get a little more clarity on the thicknesses and “pocket” depths.

UPDATE (AGAIN):

Thanks for the files, and so sorry I somehow overlooked them. I guess trying to run four 3D printers plus trying to setup and output gCode for my LowRider2 was biting off more than I could chew and somehow I got confused!

Quick heads up:

In the LR3 files I downloaded from Printables.com, the “YZ plate left” and “YZ plate right” files, seem to be misnamed as “xz-plate-left” and “xz-plate-right” (note they start with X instead of Y). I think this because the very same part set is, on the LR3 Doc page, called “YZ Plates” and “YZ Plate DXF Mirrored set” and “YZ Plate DXF” and “YZ Plate STL.” So, I suppose it’s possible they are misnamed on the Doc page instead of on Printables, but the naming does not match between the two locations.

UPDATE:

Thanks for the clarification, and so sorry I somehow mistook that file naming for a different file contents. I’m still not sure how it happened, but I could have sworn when I opened the downloaded files from Printables, the XZ showed exactly like the YZ. I’m chalking it up to operator error due to foggy brain!

You can print the XZ plates as shown in this picture, or cut them with the specs listed in the DOC’s. You seem to be trying to print the dxf?

I believe the dxf file(s) are for the YZ plates, not the XZ plates.

There are 3mf files of the XZ plates on printables, xz-plate-left and xz-plate-right.

Unfortunately due to their size, I do not believe that the YZ plates are printable on a standard size 3d printer, hence the reason Ryan furnished a dxf file for machining them.

If you look in the store, you will see very nice photos of both the XZ and YZ plates.

Either that or I am totally confused on what Doug is pointing out, which is a very real possibility.

Re: wanting STL/3MF file:

Thanks for the files, and so sorry I somehow overlooked them. I guess trying to run four 3D printers plus trying to setup and output gCode for my LowRider2 was biting off more than I could chew and somehow I got confused!

Re: mistakenly thinking XZ showed exactly like the YZ

Thanks for the clarification, and so sorry I somehow mistook that file naming for a different file contents. I’m still not sure how it happened, but I could have sworn when I opened the downloaded files from Printables, the XZ showed exactly like the YZ. I’m chalking it up to operator error due to foggy brain!

3 posts were merged into an existing topic: LowRider 3 CNC, LR3 Release notes

Hey would this sheet called Hardie Backr be a good choice to use for the strut for the LR3? It’s 1/4” thick, 3‘ x 5‘. Cost less than 10 bucks at Lowes.

Update.

Never mind. I see that it’s made of concrete. Probably a bear to cut — perhaps impossible to cut. And it’s probably too heavy.

I destroyed a couple carbide tipped saw blades on hardy board our construction crew left behind. Abrasive discs seem to work much better, but it still chewed that one up pretty fast.Maybe if you were cutting slow with an aggressive jigsaw?

It’s heavier than plywood, though. I actually just brought a full sheet of each into the shop, and even though the hardy is thinner, it’s noticeably heavier than the plywood. Maybe at 1/4 in, and if you had enough cutouts, it could be a negligible difference, but I think you’re right about cutting it. Definitely not for the faint of heart.

Had my house resided in it 5 years ago. Tough on blades, will not hold a screw to save your life. As tough as it is, at the same time, can be very brittle.