Sorry I am in and out all day…the next few days. Moving.

You will need to enable the C axis in the X section and as long as you do not have a endstop pin defined I think that is considered a clone.

Sorry I am in and out all day…the next few days. Moving.

You will need to enable the C axis in the X section and as long as you do not have a endstop pin defined I think that is considered a clone.

No apologies required. Seems like last time I was getting into things you were moving too!

Happy to share the first signs of life!

Sounds like some clickety clack to look into.

Lucky day! Only one stepper plug to flip and everyone is moving in the right direction. I maintain I still hate crimping DuPont connectors. I’m going to see if I can find a 6x2 already wired block and just solder the limit wires to that. These double DuPonts are so touchy (I know, I know, it’s not the DuPont it’s the guy that made them…)

Worst case I’ll pull these ones and slot them into the 6x I have in my kit. At least they can “help each other out” then.

I think I’ve found yet another kindred spirit through the V1E universe. Hahahha

I have been dissatisfied with the crimper I have, even though it seems well-made, I get the feeling it is not quite the right one for the common cheap “dupont” connectors. I seem to have gone down a rabbit hole and found what might be a better crimper and if so, I just need the right technique.

If I may ask, what crimper do you have? I might start a separate thread on what I’ve learned after my new crimper arrives.

Cheap. Yup. I have success maybe 70% of the time? The issue here today is that the wire is pretty soft silicone wire and a bit big in the insulation dept for this size of connector. I’ve since begun crafting a Discount controller-esque ribbon. Cost me $1.25 at the electronics supply. Should be perfect and I’ll trust it much more. I did have to snip the two pins between the probe pins and the Z2 pins. Hopefully Ryan doesn’t develop some magic add-on that would have used those two ![]()

Oh! And while digging around looking for something in the 5x2 department (the mess in my office) I came across this relic. Thought you’d all enjoy seeing it. This was my first foray into desktop CNC that never got completed. It was an Instructable from back in like 2008 or so.

Looks like mine. For uninsu lated recep tacles.

After crimping, the pins are too wide to fit in the housings unless I crush them a bit more with pliers.

I can’t even remember what project I bought the crimpers for. Maybe it’ll come to me. But when I bought them I was directed to a YouTube video of some guy who really explained it well. It was a two step actually maybe three step process. I do remember the first step and that was to put the pin/socket into the crimper somewhere specific but upside down. The purpose was to ever so slightly curl the wings that grip the wire insulation so that when you did the actual crimp the wings would wrap around and hug the insulation proper like. And then I think you had to slide the whole unit back for one more final crimp and that would get it to fit the plastic bit.

So prebend, first crimp to secure the insulation, second crimp to finish the wire capture and crush all uniform.

My crimps today were two step at best but I’ll still blame the extra thick and rubbery silicone insulation ![]()

Okay, I think I’m ready to see if I can handle this. Where/how do I accomplish such a feat?

Cool! I just subscribed to your YouTube channel. Here’s mine:

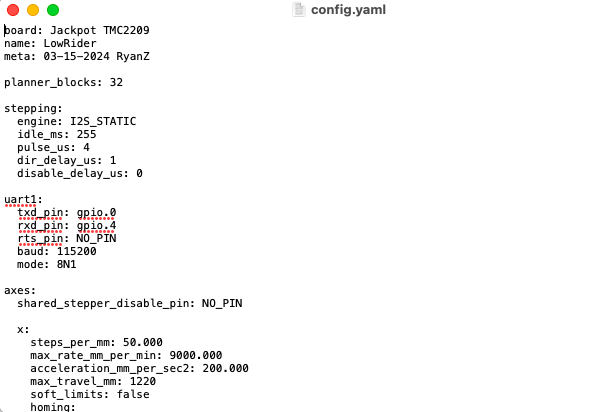

For Jackpot, this is done by simply editing your config.yaml

If you google this task and/or check the docs and/or search the V1E forums, you should get some clarity. If not, I will try to circle back and help, but it will be a while because I am swamped right now.

I just got home, I am pooped. I will try to tackle this in the AM over some coffee.

The yaml file will get a edit with a text editor, then just uploaded and overwritten, reboot and it should be good.

Might take a test or two to figure it out, but it should be simple as this is how most other machines work (without dual endstops).

I’m game to toy around. You guys all made me quite comfortable with the process back in the MP3DP days. I assume I grab a fresh config file from the respository and play from there? Is there any risk of bricking anything?

I spent some time last night reading through the FluidNC Wiki and the Jackpot docs. Not that a lot of it made any sense but I know the more I expose myself to it the more I’ll recognize things people say in the forums and slowly it’ll all gel.

Have a look at my X axis setting for the MPCNC. It should be very similar except for the limit switch settings and pulloffs. I’m not sure how that will differ so I’ll let @vicious1 guide you there.

#X

motor0:

limit_neg_pin: gpio.25:high

limit_pos_pin: NO_PIN

limit_all_pin: NO_PIN

hard_limits: false

pulloff_mm: 2.000

tmc_2209:

uart_num: 1

addr: 0

cs_pin: NO_PIN

r_sense_ohms: 0.110

run_amps: 0.750

hold_amps: 0.500

microsteps: 8

stallguard: 0

stallguard_debug: false

toff_disable: 0

toff_stealthchop: 5

toff_coolstep: 3

run_mode: StealthChop

homing_mode: StealthChop

use_enable: false

direction_pin: I2SO.1

step_pin: I2SO.2

disable_pin: I2SO.0

#C

motor1:

limit_neg_pin: gpio.35:high

limit_pos_pin: NO_PIN

limit_all_pin: NO_PIN

hard_limits: false

pulloff_mm: 2.00

tmc_2209:

uart_num: 1

addr: 3

cs_pin: i2so.22

r_sense_ohms: 0.110

run_amps: .75

hold_amps: 0.50

microsteps: 8

stallguard: 0

stallguard_debug: false

toff_disable: 0

toff_stealthchop: 5

toff_coolstep: 3

run_mode: StealthChop

homing_mode: StealthChop

use_enable: false

step_pin: I2SO.21

direction_pin: I2SO.20

disable_pin: I2SO.23

I’ve found the config.yaml from Ryan’s github. Now the trick is opening it. I’m on the Mac side and when I open it it up it is all formatted and hyperlinked etc which I’m sure is not the way to tinker with this file. Any other Mac users out there?

Ignore me for a while here. I’m so quick to ask questions here (because you are all so quick to help) that I don’t bother digging myself which is a far more valuable way to learn. I found this and will continue poking around. I need to get to know this stuff not just be “led to the water”…

Many changes to the config can be done through that user interface, but some “more off the beaten path” changes need you to open the config file in a text editor and do some editing there. This will be one of those cases. Just be sure when you open it in the text editor that it is an editor that saves, or can save, in the standard UTF-8 encoding method.

I recommend making a copy for backup purposes, so you can refer to it again if you need to, and then make your changes to the original.

Edited to add: be sure it is a plain text editor. You do not want a word processing program adding “word processing” rich text coding nonsense to the file.

Making progress! ![]()

Okay, let me think this through here. I see the X, Y and Z sections and all the settings but the important bit in this case is the difference between the Y & Z and the X. The Y and Z both require two motors and in the config I see “motor0” and it’s definitions and then I see #A followed by “motor1” and it’s definitions. Looking to Z I see the same, the difference being the reference to #B instead of #A.

I’m going to assume then that WITHIN the X section I need to duplicate the "motor0 settings, calling it “motor1” and preceed that on the line just above that with “#C”? AND THEN I need to change the “motor1” definitions to ensure that "limit_neg_pin is changed to “NO_PIN”? Is that all? OR actually, should that limit_neg_pin be changed to use the exact same pin from “motor0” - so “gpio.25:high”?

[ editing to add an observation aside ]

While sitting here in the shop reading through and looking into this the machine has been powered on. There’s a subtle “machine” sound coming from it that I’d heard before but left “to look into later”. I noticed while poking around with the wiring that the board - not sure what part of the board - put out some good heat. Not hot, but heat. I’m sure this is normal and in my case I’ll welcome any little heat to help keep the electronics warm.

I did however just feel al the steppers and the second X (driver C) is warm while all the others are cool to the touch. I assume this is because it’s unconfigured as of yet?