More than a few people have complained about how terrible it is to crimp “dupont” connectors.

For the purpose of this topic, I’m discussing only “dupont” connectors, and not any others.

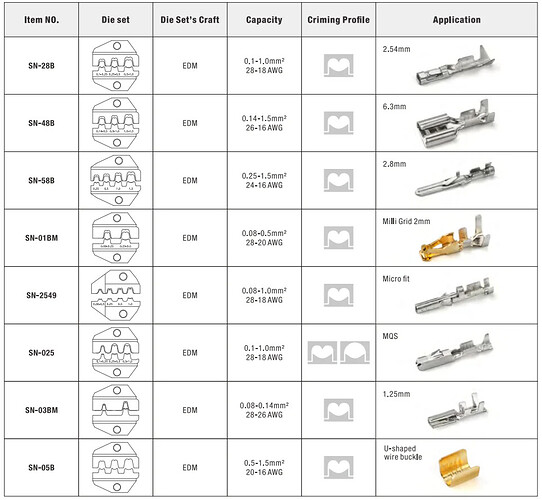

After more than a little digging, I think the culprit is the seemingly ubiquitous SN-28B. This is the one sold not just on Amazon but also by electronics vendors who you would expect to know better, like Pololu and Adafruit. I think mine were from Adafruit, and I expected they would sell the correct tool.

I always noticed that after crimping, the crimp on the insulation would be too wide to fit into the housing, and I would have to crush it a second time with pliers to get it to be narrow enough to fit.

A second thing I noticed sometimes, if I tried pulling, much of the time the end would pull off without that much force.

Based on some reading, it sounded like the SN-025 is the correct tool, so I got one to find out. This is the one I got.

It’s not any more expensive, but you have to look specifically for SN-025, rather than just looking for “a crimper” which will usually get you SN-28B.

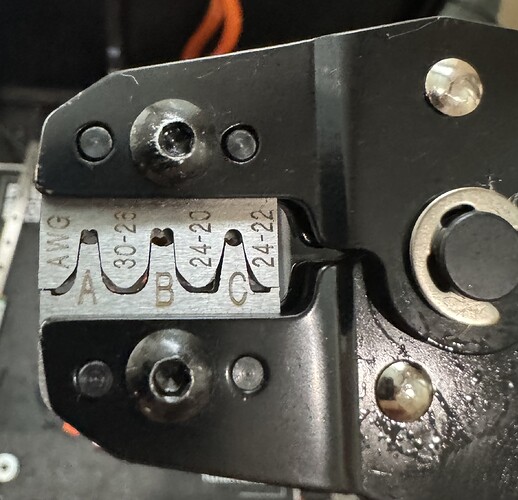

One obvious difference you can tell from looking, is the crimp on the insulation is “O” shaped rather than “B” shaped.

SN-025 (good):

SN-28B (bad):

The “O” shaped crimp on the insulation solves the problem of being too wide to fit in the housing. I tried several times and so far it’s 100% success in fitting in the housing the first time.

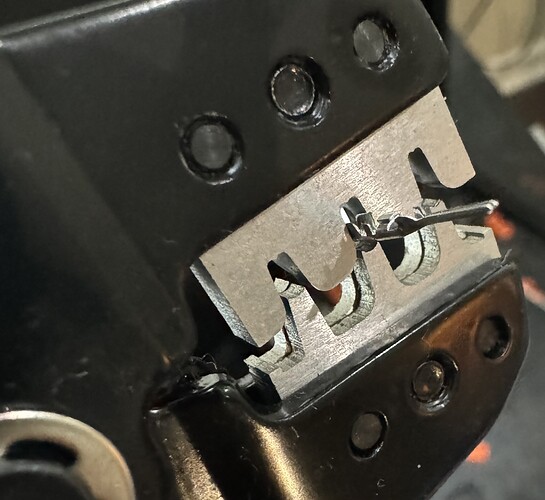

The second difference is the crimp on the wires is much tighter.

Left side is SN-025 (good) and right side is SN-28B (bad). Both are clamped all the way and the good one is visibly much tighter.

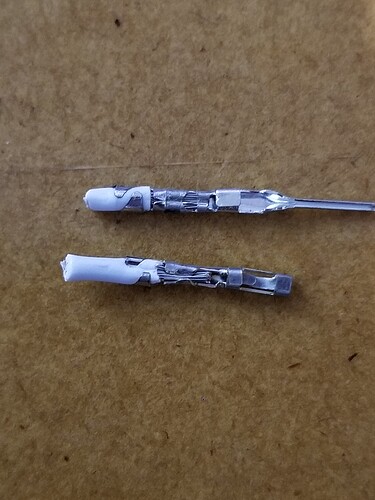

Finally here is a side by side of the results. Top result is SN-025 (good) and bottom result is SN-28B (bad). The good one wraps the insulation nicely and the bad one sorta grabs, which maybe is ok but it’s usually too wide. The crimp on the wire is the bigger difference where the SB-28B (bad) sorta halfway grabs the wire but just barely, whereas the SN-025 looks and feels much better.

There is also something if a technique but it is 90% the tool and probably several techniques work.

Here is what I (now) do:

Cut the pin from the other pins with the little tail attached.

Strip the wire with just a bit exposed, approximately the length of the matching tabs on the pin. You can strip more and cut afterward if necessary.

Line up the end of the insulation with the gap between the insulation part and the wire part of the pin.

Hold with pliers (facing toward you) where the right edge of the pliers lines up with the edge of the tail.

Place the right face of the pliers against the left face of the crimpers and hold the wire and pin within the notch. You should see the right amount of the pin sticking out the right side.

Then squeeze.

This technique is just an example and you can of course do whatever works for you.

And once again, the tool makes more difference than the technique. The SN-28B will be bad even with the best technique.