you can crank up the acceleration quite a bit. these are my conservative settings:

[19:46:19] [1:8,0:0] ==> M503

[19:46:19] [1:8,0:0] <-- echo: G21 ; Units in mm (mm)

[19:46:19] [1:8,0:0] echo:Filament settings: Disabled

[19:46:19] [1:8,0:0] echo: M200 D1.75

[19:46:19] [1:8,0:0] echo: M200 D0

[19:46:19] [1:8,0:0] echo:Steps per unit:

[19:46:19] [1:8,0:0] echo: M92 X80.00 Y80.00 Z400.00 E100.00

[19:46:19] [1:8,0:0] echo:Maximum feedrates (units/s):

[19:46:19] [1:8,0:0] echo: M203 X200.00 Y200.00 Z10.00 E25.00

[19:46:19] [1:8,0:0] echo:Maximum Acceleration (units/s2):

[19:46:19] [1:8,0:0] echo: M201 X3000.00 Y3000.00 Z100.00 E20000.00

[19:46:19] [1:8,0:0] echo:Acceleration (units/s2): P R T

[19:46:19] [1:8,0:0] echo: M204 P3000.00 R3000.00 T3000.00

[19:46:19] [1:8,0:0] echo:Advanced: B S T J

[19:46:19] [1:8,0:0] echo: M205 B20000.00 S0.00 T0.00 J0.01

[19:46:19] [1:8,0:0] echo:Home offset:

[19:46:19] [1:8,0:0] echo: M206 X0.00 Y0.00 Z0.00

[19:46:19] [1:8,0:0] echo:Unified Bed Leveling:

[19:46:19] [1:8,0:0] echo: M420 S1 Z0.00

[19:46:19] [1:8,0:0] Unified Bed Leveling System v1.01 active

[19:46:19] [1:8,0:0] Active Mesh Slot: 0

[19:46:19] [1:8,0:0] EEPROM can hold 32 meshes.

[19:46:19] [1:8,0:0] echo:PID settings:

[19:46:19] [1:8,0:0] echo: M301 P30.65 I3.53 D66.45

[19:46:19] [1:8,0:0] echo:Z-Probe Offset (mm):

[19:46:19] [1:8,0:0] echo: M851 X-30.00 Y0.00 Z-3.25

[19:46:19] [1:8,0:0] echo:Stepper driver current:

[19:46:19] [1:8,0:0] echo: M906 X760 Y760 Z800

[19:46:19] [1:8,0:0] echo: M906 T0 E1100

[19:46:19] [1:8,0:0] echo:Hybrid Threshold:

[19:46:19] [1:8,0:0] echo: M913 X201 Y201 Z10

[19:46:19] [1:8,0:0] echo: M913 T0 E0

[19:46:19] [1:8,0:0] echo:StallGuard threshold:

[19:46:19] [1:8,0:0] echo: M914 X255 Y255

[19:46:19] [1:8,0:0] echo:Driver stepping mode:

[19:46:19] [1:8,0:0] echo: M569 S1 X Y Z

[19:46:19] [1:8,0:0] echo:Linear Advance:

[19:46:19] [1:8,0:0] echo: M900 K0.40

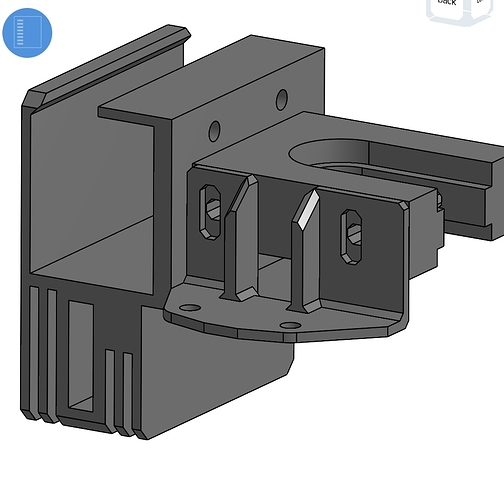

I also ended up getting the genuine V6s. One thing that’s easy to overlook but critical: check that your set screw on the filament drive gear is always tight (and on the flat). It can work itself loose and give you no end of trouble that’s really hard to diagnose. For that matter, make sure all the screws on the drive head are tight. This is far more important on bowden drives than direct drives.