I want to document the build for my next 3D printer, and I took over another topic for a while, but as the parts are rolling in, I want to make my own clean topic. @stewart, I’ve moved over here ![]()

I have been following the BOM, and I have a lot of the stuff already. I ended up ordering the screws from bolt depot, and getting a lot of boxes of 100 instead of the 20 I would need. No sense in paying someone to count them when they can just send me extra. I didn’t see the hammer nuts in the BOM, and some of the screw sizes weren’t perfect, so I ordered one size longer for those. I suspect I can make them work. The flanged LM8UU bearings were supposed to take weeks, but they are here already. The only 8mm rod I found was 500mm, so I have to cut those down. It looks like I need it between 444mm-447mm, and I think I can hit that range. I’m going to shoot for 446mm.

I haven’t found any 1/2" square tube yet. Hobby king has been out of stock, and unless there are a bunch on a boat to their US warehouse, my guess is it would take at least a month to get them from there. So I may design the bed mount around another sized tubing, cut it from one plate, or maybe the local metal super market will have something I can fit.

I haven’t used a bowden before, but I ordered a trainglelabs BMG bowden extruder. I’m not sure the dual gears matters with a bowden more or less than a direct drive :). I ordered the V6 hot end from the BOM. I have a similar one and it works great.

I’m going to convert my CNC to the grbl_esp32 board I have, and use the skr with this printer. Hopefully I will be cruising at such high speeds, the 32 bit will matter (but probably not).

I ordered the 450mm 2020 from misumi, as per the BOM, and they were pretty cheap, and I’m happy with the straightness and squareness of the cuts. I doubt I could have cut them this cleanly.

Here is another picture. Wanhao for reference. Going from an 8" bed to a 12" bed, but not much more desk space.

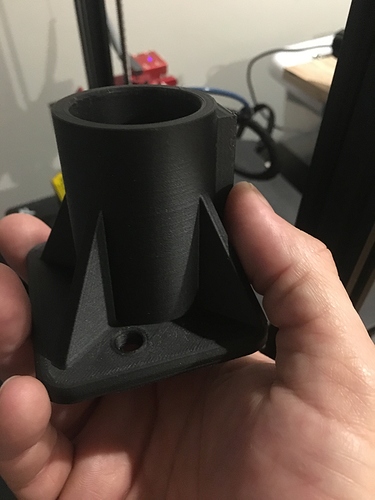

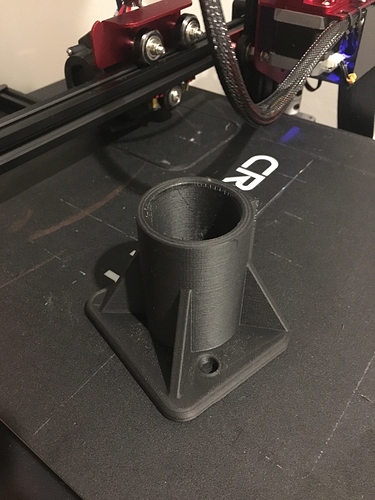

I’m using Joel’s High Five HTPLA from Proto-pasta, but I ran out yesterday. I love the look, and maybe the HT will benefit it for one or two parts. I should have some more coming today.

Obviously, these dedicated shippers are quickly making me look bad. I will have almost all the bought parts, and weeks of making my own parts left.

Update: The details I’m following are (currently) liked from grid.space :

CAD Model, in OnShape

Bill of Material (BOM)

Software

Open Builds

Image from the CAD drawings:

Another post with detailed photos:

But if you hit any snags, don’t worry about it. There is a metal supermarket about 20 mins away, and it would probably cost about $20. It wouldn’t have exactly the same inside profile, but I’m sure it would work. I’m not sure exactly how they dimension the thickness of the tubing, but it says 0.065in, which is thicker than the HK, including the little rib.

But if you hit any snags, don’t worry about it. There is a metal supermarket about 20 mins away, and it would probably cost about $20. It wouldn’t have exactly the same inside profile, but I’m sure it would work. I’m not sure exactly how they dimension the thickness of the tubing, but it says 0.065in, which is thicker than the HK, including the little rib. .

.