Is it possible to use closed loop steppers with jackpot?

I’m not aware of anyone using closed loop steppers with the Jackpot. It would require using external drivers which I’m not 100% sure if anyone is doing that. A few have talked about it and I know of at least one who tried it but I’m not sure. Maybe. It’s certainly not the path of least resistance and isn’t necessary for good performance.

What’s prompting you to ask the question?

As Jason said: that’s the biggest problem. There has yet to be someone to get the jackpot working with external drivers.

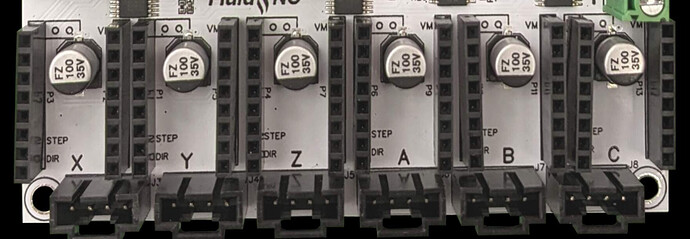

Connecting external drivers is possible via the Jackpot. Just connect the external drivers to the corresponding port on the Jackpot .

With little problems i can find dir and step here.

lowrider has only two weak points: belts and steppers. Y belts are not so critical, but X - is pain. closed loop is very good solution as well, 1/5 of pure servo cost. But much much much muuuch more serious.

changing cheap stepper to closed loop, and adding ball screw to X would make it 99% professional serious machine

![]()

![]()

![]() I know a couple or more hat will get triggered by some of this words…

I know a couple or more hat will get triggered by some of this words…

Humor aside. Dialling in your feeds and speeds is by far the biggest improvement.

did u already try this? Is it just so simple? ) Please help me understand all details, so i would order closed loop kit immidiately.

I agree with you on the closed loop stepper on X after having tested it. From the topics you’ve posted so far I can not see a working machine on your end, the circles you drew with a pen are all over the place. So it first and foremost it does not seem to be a problem of the machine.

I run the LR pretty close to its max, the next thing I’d break are some of the plastic parts, the belts are definitely not the problem.

Then please do so. We have two or three topics around here where people said the same thing, but there isn’t a working config so far. You’d help everybody out by doing it “with little problems”. ![]()

Cl steppers that will fit the Lr4 motor mounts for z &y axis will be really underpowered,

No, the magnetic ones from Stepperonline have the same measurements the non-CL have. So there are options but they have not been tested and I am too broke to test it. ![]()

The signal is the same, should work. All these boards are basicly the same.

I don’t have a Jackpot nor closed loop steppers and drivers.

See my post of my setup : New build : two years later

All machines that are driven by belts - are complete fail when we would try to do small and precise work.

there are only two working solutions: ballscrew and magnetic guide. See the price of the magrails - there is only one left)

K, what are you working with that need that much of precision?

Can u show me 5mm round circle on 200*300cm machine?)

Seems that we have different understandings of what is “that much” )

Thats one of the examples and with a way less rigid machine than the lr4.

It all depends on how well you build yours and how well you dial in your cutting settings

Ok what you need to do with your machine?

I mostly work cutting and routing acm sheets, my 2 previous lowrider versions were up to the task, 2 lr4 on the way, only the lr2 is going to be retired.

I have a 2 workbee cnc one is on v-wheels with rack&pinion (plastic) and the other is heavyly modded (no vwheels, ballscrews on x &z ) and i cant find any difference in a sheet of acm that i can tell it was made on the lowrider, -my feeds&speeds are almost the same for cutting with the spiral single flute and especially the V bits i use, i run the amana recomended profile (1440mm/min)

There is no need to up the cutting speeds: bits deflects, you may kill or make your bits dull sooner and thats a waste

You did see my tiny inlays, right? With a full-size gantry. ![]()

Yeah, that’s the theory. It’s not working for anyone just yet though. ![]()

Man, you have everyone here with the envy ![]() with those inlays.

with those inlays.

lol. Too big size. I’m out. Your round holes are not circles.