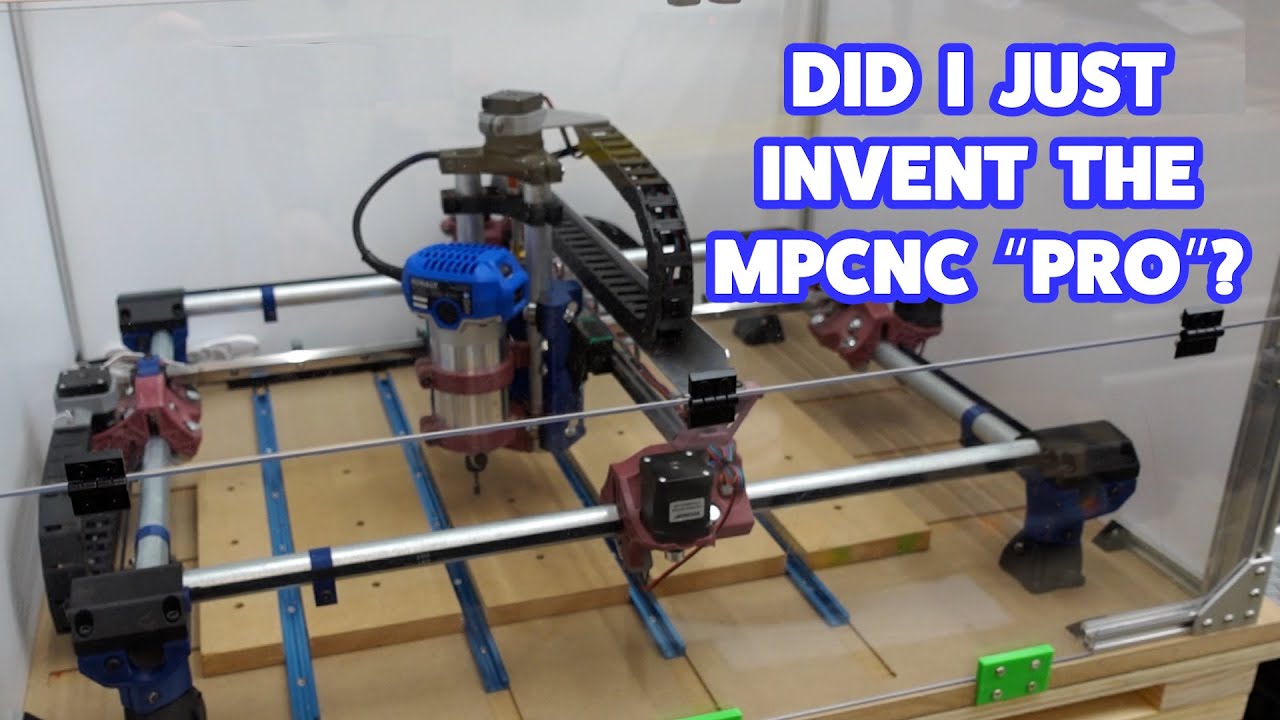

A solid success cutting aluminum on the MPCNC, with a 17"x13" volume. I included the feeds, speeds and settings below (and in the video):

This isn’t a stock MPCNC though. If you want to see the upgrades I made to it, see this video:

Cut settings:

- Bore holes:

- 1.9mm single-flute carbide

- 34,000 RPM

- Feed rate: 300 mm/min

- Ramp angle: 2 deg

- Contour/Profile cuts:

- 3.175mm (1/8") single-flute carbide

- 26,000 RPM

- Feed rate: 400 mm/min

- Depth of Cut per pass: 0.4mm

- Stock to leave: radial 0.2mm (for finishing pass)

- Finishing pass, full-depth (3mm), to remove last 0.2mm of edges

- Repeat finishing pass

- Countersinks – I continued using flat endmill, stair steps via “Ramp” operation

- 3.175mm (1/8") single-flute carbide

- 26,000 RPM

- Feed rate: 400 mm/min

- Max stepdown: 0.4mm

- Cusp height: 0.3mm

- Chamfer edges:

- 1/2" 45deg (90deg full) V-bit

- 18,000 RPM

- Feed rate: 400 mm/min

- Chamfer width: 0.3mm (amount of chamfer)

- Chamfer tip offset: 1.5mm (tip of V-bit will be this far below top of workpiece)

All these settings do produce quite a bit of “dust” instead of chips. But I’ve found these to be reliable settings for boring and contouring aluminum and getting really good precision. I don’t even need to use lubricant or coolant. I bought a bunch of bits on Amazon, and expected to blow through them, but in a few hours of cutting aluminum with each bit, I still haven’t broke any !?

When I do need to clear out areas, I use “Adaptive Clearing” (Fusion360’s trochoidal toolpaths), and I usually use a DOC 4mm, 500-600 mm/min, 26k (1/8" bit) or 22k (1/4" bit) RPM, and ~8-10% stepover (so 0.25-0.3mm for 1/8" bit, 0.5-0.6mm for 1/4" bit).