Why not mount it near the 0,0 of your table where it will get used the most?

At first I thought you were talking about the phone. I realize now you were talking about the charger!

That looks really great, and with a great result.

And proves keeping lots of copper away from that ESP32 antenna is the key consideration.

Not some wacky theory about water absorbed PLA…

That might block the antenna again…

Yep.

Potentially yes to both.

That sounds like sage advice to me.

Hi Doug,

I just wanted to make a note here that Ryan addressed this concern (with “addr:” not being unique) in my long thread on the ESP32 connection issues.

Some do share an “addr:” in the config because of the way they’re connected. The link above is to my question about it, and the answer is just a few posts down.

TL;DR - Ryan’s config is correct.

Glad you got it. I agree about mounting the phone near 0,0

Got it! Will switch it back!

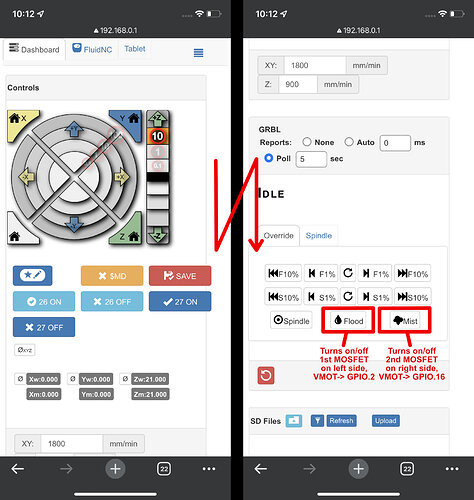

Details for switching on/off the MOSFETs via either GUI buttons or in GCode:

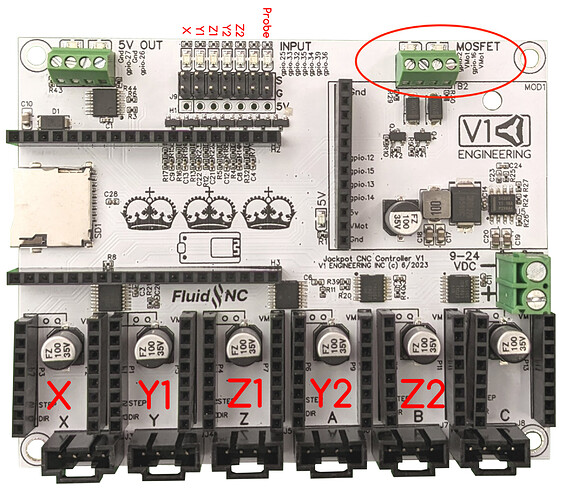

Location on the board (upper right corner):

GUI buttons

In the FluidNC web-based GUI, the buttons labeled “Flood” and “Mist” turn the MOSFETs on/off:

GCode

According to the FluidNC WIki — Supported Gcodes | Wiki.js …

M7 / M7.1 - Mist Coolant

- M7 ; Turns on 2nd MOSFET on right side, VMOT-> GPIO.16

- M7.1 ; Turns off 2nd MOSFET on right side, VMOT-> GPIO.16

M8. / M8.1 - Flood Coolant

- M8 ; turns on 1st MOSFET on left side, VMOT-> GPIO.2

- M8.1 ; turns off 1st MOSFET on left side, VMOT-> GPIO.2

OK, so I got my first successful dry run test with the new Jackpot board.

Now I need to recheck and adjust my gantry for being trammed with the spoil board, and recheck and adjust for squareness on the X and Y.

After that I think I will be back in business.

OK, I solved another issue, and its cause was the same as a previous mention: in my config.yaml file, I had stray trailing spaces after a value. This resulted in my Z1 stepper moving much faster than Z2 stepper. It was descending and ascending faster. When I carefully examined the Z portion of my config.yaml file, I found the trailing spaces, deleted them, re-uploaded the revised file, rebooted the Jackpot board, and all was correct on the Z movement!

I’m wondering if they used this “true positioning” code to save memory space so they don’t have to add a searching algorithm. Or if they used the actual coding language whitespace for the same effect but different reasons. Just seems like more of a hassle for developers than it’s worth saving memory, but I’m sure they had their reasons. Hence my curiosity

The config file is bog standard YAML. Yaml has these particular quirks. It may be slightly more restrictive in a microcontroller, but leading whitespace and the spaces around the colon are critical. It is a markup language and you’re talking to a dumb computer. So you have to be precise. It is definitely more forgiving and less ugly than html and more useful than .ini. The config file needs to be treated like code and every character can make a difference.

The significant problem I see is the feedback seems to be missing. You can’t tell that the driver isn’t being configured until the motor gets hot. That seems like a real problem. You’re an expert user, so you know it is too hot. A novice might think that is by design and just hate the machine or themselves.

The issue Britt had with the power order really bothers me. We need to find a way to get an error message if the driver hasn’t been configured, or the config file has an error in it. Something that tells you a key error message you can search for, at least.

New version of the case has been published!

Maybe some sort of boot sequence, or LED flash. I like the idea of a self check on boot.

This is not useful for anything but commiserating, but YAML drives me crazy sometimes. I have grown to love and embrace JSON as a favored alternative.

A check on that file would definitely be a good idea.

It could even be a syntax checker that runs on the web or PC.

Mike

I was thinking this. This way theres less chance something gets missed by the controller. I know I know it can still happen but a web check would be easier to roll out updates and stuff. Wouldn’t need a new firmware each time

I’m super used to running a syntax checker on automated test procedures that I write before I ever run them.

Since the yaml seems to be picky, why not have a strict syntax checker? Better to know. (Better still to have FluidNC spit out good error messages, but that’s an aside.)

I could argue that for config, JSON is overkill, and annoying in its own ways. Especially if you end up dealing with a mix of strict and permissive JSON parsers… I will grant that for inter-process communication, JSON is 100% better than XML, even if you don’t end up with fancy, polite documents lite DTDs and the like…

Any markdown is going to get hate. I was just trying to point out that it wasn’t FluidNCs fault (but I am in camp yaml).

There are online yaml checkers. There are very strict linters too. The trouble is making sure the checker is up to date with the code. And if you have the wrong whitespace, that can sometimes lead to valid, but logically incorrect yaml. Like putting a parameter for a motor in the next scope. A generic yaml tool won’t be able to help with that. A fluidnc specific tool will be expensive to upkeep.

There isn’t a perfect solution and at the current scale having volunteers debug issues for the people that have them is close to the best solution. But I just want more notice to people that they have a problem. Double checking that the tmc settings were accepted is a start. Making sure the current setting was set would be nice to have. Maybe some automatic double checking like: You set this driver type to TMC2209, but you haven’t set a current limit (because the yaml is wrong and the current is in the wrong section).

Please forgive the double post. This seems to belong here as well as the thread on the case itself.

I laser engraved the lid, using a 100W CO2 laser, at 300 mm/sec, with 45% power.

When cleaning away the debris, avoid use of astringents, etc (including avoiding alcohol and WD-40 or the like) as it will cause micro-fracture cracks in the edges of your engraving. I made this mistake (alcohol), but then was able to correct it with careful use of a heat gun. Be careful with a heat gun, as you can overheat it and cause bubbles and ripples and ruin the appearance. I did not make the latter mistake this time, but I had made that mistake before on another project. (Open sharing of mistakes will hopefully prevent someone else from making the same ones.)