Printables download link for my remix of the case: Printables

Differences of the remix compared to the original

Lower part of case (case bottom) is 7mm deeper than the original, to give more room for getting power to the M5 Stack dial. Also the screw wells on the bottom of the lower case are slightly larger, as I found they weren’t quite large enough on the original. Upper part of case (case top) is altered to allow printed logo medallions to be inserted/glued in. The printed logo medallions are included. Both the original case parts (top and bottom) are included as well, for mere convenience, and the graphics for printing a paper graphic top to glue onto the original lid is also included. I’m also throwing in Fusion 360 solid bodies of the original case bottom, and the modified case top, as well as SketchUp file (remixed mesh) of the case bottom with the added depth.

Description from the Printables listing

NOTE: the pendant is still under development, so unless you want to be on the bleeding edge, consider waiting a bit before diving in.

See my full build log of this, on the V1 Engineering Forum here: Fluid Dial (Fluid NC dial pendant by Bart Dring, using M5 Stack's M5 Dial)

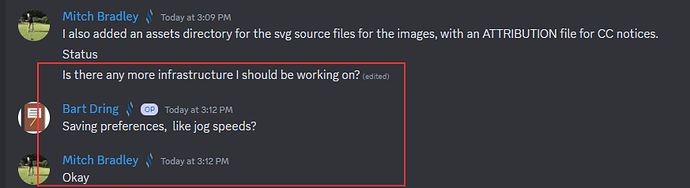

A huge “shout out” and thank you to Bart Dring, Mitch Bradley, and Michael Melancon of the Fluid NC dev team, and also to Ryan Zeller, @vicious1 over at V1 Engineering Inc, and all the helpful crew at the V1E forum! If you benefit from their amazing work, consider joining me in donating to help them continue their work.

The project’s wiki is at: M5Dial Pendant | Wiki.js

The original case (and firmware and other resources) can be accessed in the project’s Github repo, at: https://github.com/bdring/PendantsForFluidNC/tree/Files/M5Dial_Pendant

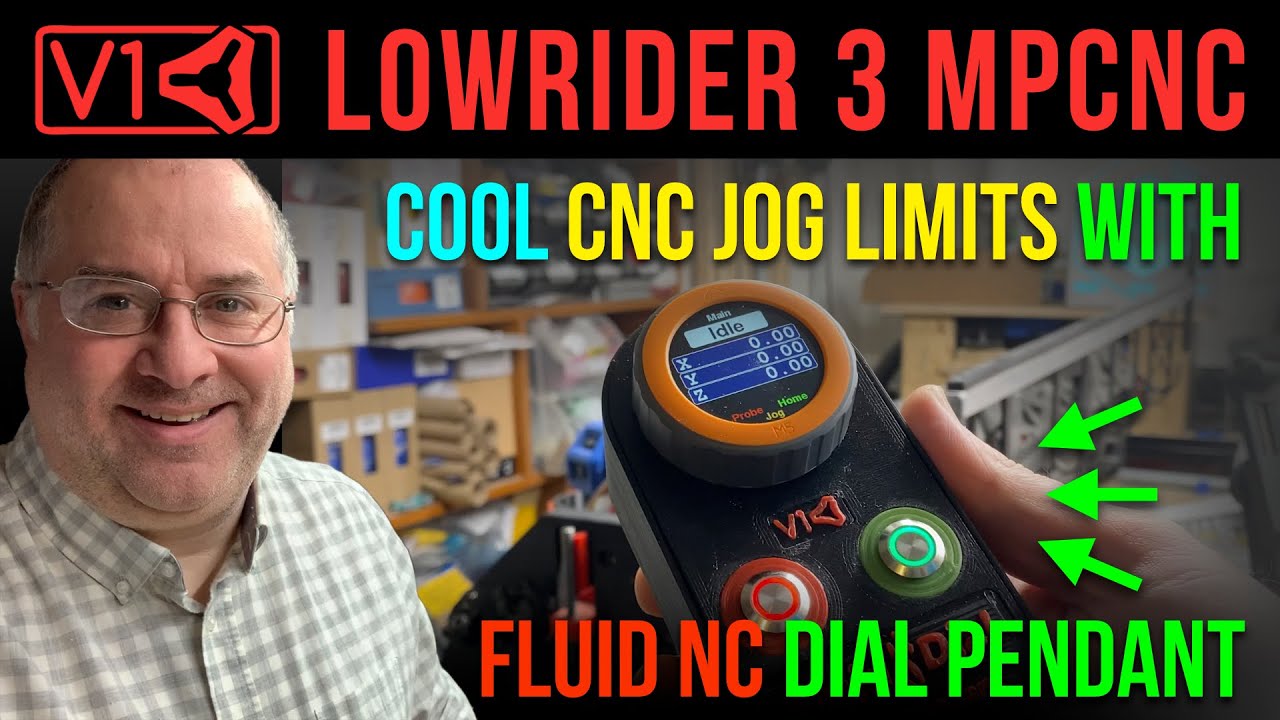

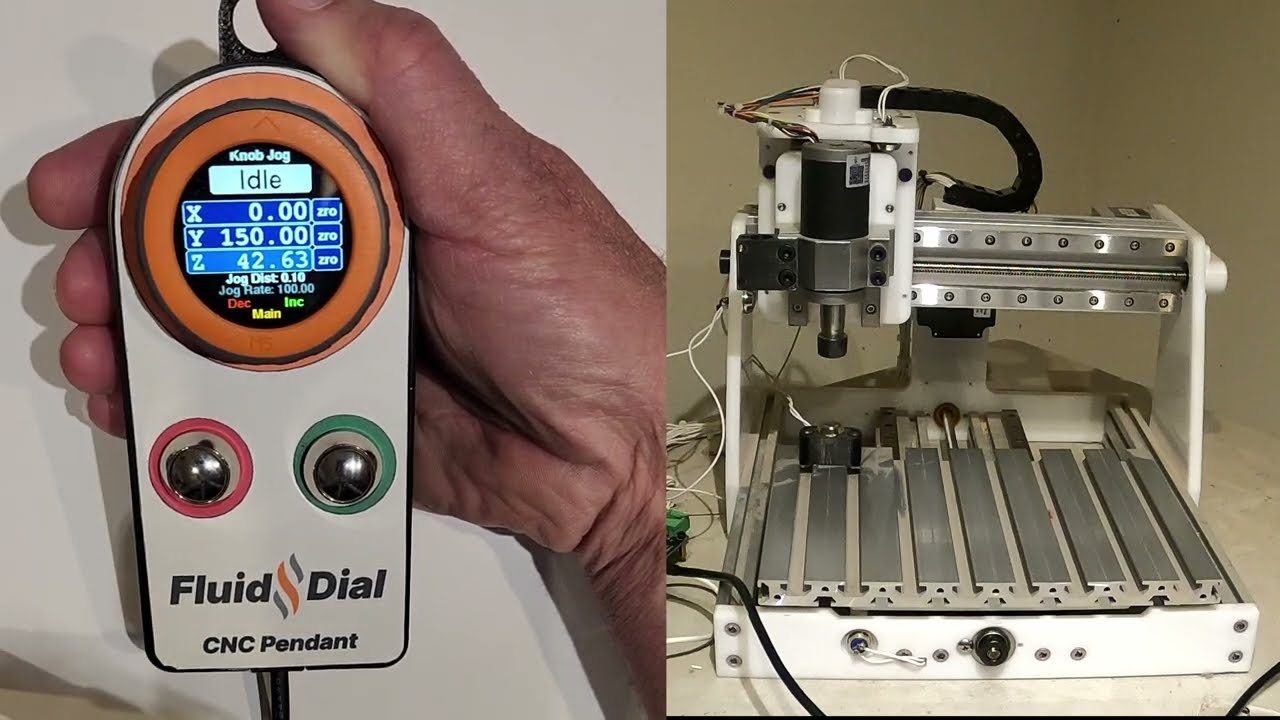

Watch these videos to see the CNC pendant in action:

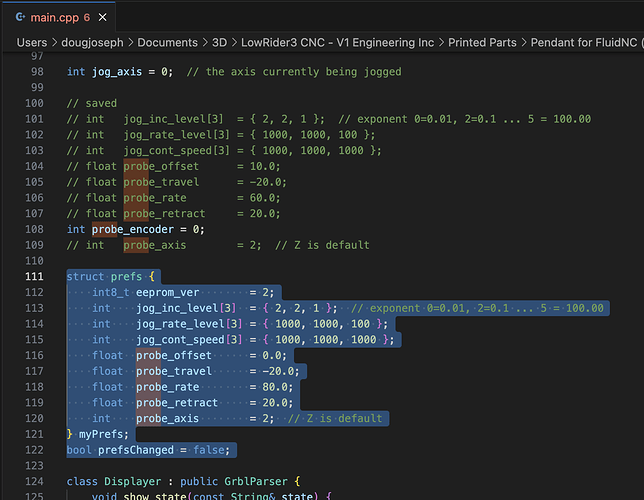

What’s changed in my remix?

- Lower part of case (case bottom) is 7mm deeper than the original, to give more room for getting power to the M5 Stack dial.

- Upper part of case (case top) is altered to allow printed logo medallions to be inserted/glued in. The printed logo medallions are included.

What’s available in this listing?

- Remixed case bottom (extended for 7mm extra depth)

- Remixed case top (modified for logo medallions, printed separately) to be glued in.

- Printed logo medallions.

- DXF graphics files from which the logo medallions were created.

- Both the original case parts (top and bottom) are included for convenience sake, in both STEP and STL formats.

- The original graphics PDF file — for printing a paper graphic “top” to glue onto the original lid is also included. (If you are going this route, you don’t need print the logo medallions or the modified lid.)

- I’m also throwing in Fusion 360 solid bodies of the original case bottom, and the modified case top, as well as …

- SketchUp file (remixed mesh) of the case bottom with the 7mm of added depth.

The original is released under the GNU GENERAL PUBLIC LICENSE, and accordingly, so is this listing.

Change log

- December 28, 2023 — Initial v1.0 uploaded.

My PayPal tip jar: https://paypal.me/design8studio

Various LowRider 3 CNC remixes:

View all my models and remixes on Printables:

*Product links may be affiliate links, which add nothing to your price, but may benefit me by a small percent.