Learn something new everyday.

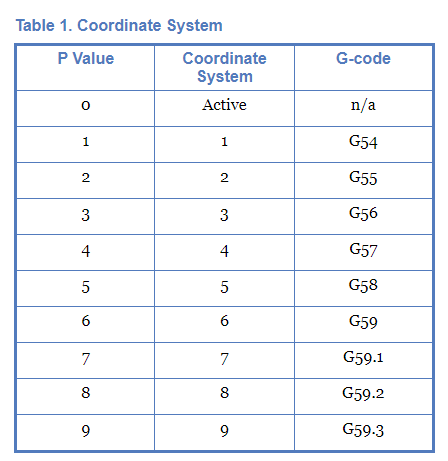

G54 you use to say “Use Coordinate System 1”

G10 L20 P1 X0 Y0 Z0 says “For coordinate system 1, set the current position as the (0,0,0)”

G10 L2 P1 X5 Y5 Z5 says “set the global position of (5,5,5) position as the (0,0,0) for coordinate system 1”

At least that’s how my 5 minutes of research has made me understand it… #stillanoob

So, I think you are right in that it could help in recovery, as the offsets from “Home” would be stored, and you could get back to your last job origin easily, so long as you are consistent in which workspace you are using.

I’m not sure if there is a way to parameterize it though so that you could, when generating a file, say “Use Coordinate system 3” which would change to “G56” and “G10 L20 P3…” when it generates the GCode rather than having to be sure to change them correctly

Otherwise, you are basically just always using G54 “Coordinate System 1” instead of “Global Coordinate system”

Good news.

Soft limits and hard limits still work even when I use the pendant to set a different 0,0 for XY, video soon!

This is likely due to the use of G10 instead of G92 as we “guessed” above

Or maybe it is a case of the more you know, the more you realize you do not know.

So G92 that survives a reboot?

The same as setting your workspace offset…or is the the way you do set a work offset…dang

@vicious1

G10 L20 P0 applies to the “Active” coordinate system, so it is always safer to use and will work regardless.

Edit: (ugh…I told myself I wasn’t going learn this today…)

Uggghhhhh that means I need to update the docs…

(when I am sure I understand it all the way, I think I do, but I need to be sure)

I “think” I understand it, but it’s hard to type-splain it ![]()

![]() I do that with so many things each day. I have learned way too much already today, for it being 10am.

I do that with so many things each day. I have learned way too much already today, for it being 10am.

I’m running on a short night = low sleep, and still learning! #Noobs_of_CNC_unite

For all intents and purposes around here G10 L20 P0=G92. It just adds benefits if needed (recovery, soft limits that will work, ease of repeated jobs, ease of introduction to workspaces)

I think the short answer is, you can replace G92 with G10 L20 P0 everywhere and it will work, and be better in the long run, even if you never invoke any of the G54-G59 commands to actual use one of those coordinate systems

Well thanks boys, I feel like I need a beer before my brain explodes.

THIS = definitely how I already work and use the “zero x / zero y” buttons!

And this is why it’s always better to work for yourself…10am beers ![]()

G92 applies on top. It’s an “additional offset”, so I think there’s danger in mixing use.

G53 can be used if you are in a different coordinate system, but you want to use machine coordinates for your command

G53 G0 X10 Y10 Z10 (rapid linear move to the global machine offset (10,10,10))

@vicious1 , @Michael_Melancon , @SupraGuy and any others who may be interested. Here’s some video:

Ryan, here’s a “warning” I gave in the video description (bolded part):

NOTE: the pendant is still under development, and unless you want to be on the bleeding edge, consider waiting a bit before diving in.

See my full build log here on the V1 Engineering Forum: Fluid Dial (Fluid NC dial pendant by Bart Dring, using M5 Stack's M5 Dial)

A huge “shout out” and thank you to Bart Dring & Mitch Bradley & Michael Melancon of the Fluid NC dev team, and also to Ryan Zeller @vicious1 over at V1 Engineering Inc, and all the helpful crew at the V1E forum!

I can think of one use case that you might use- taking a machine into a really bad WiFi environment and still wanting to control a demo machine. Yes, this could be done with a display/LCD on the machine as with the SKR Pro / LCD. But no such thing for FluidNC. So the pendant could let you demo/operate the machine without suffering from WiFi hell.

If it were easy to connect/disconnect from a running machine you could even move it between multiple machines.

That’s a very niche use case, very much unlike most folks’ work flow.

I could also see wanting to control the machine without WiFi in use. A production machine that runs the same job(s) over and over without much movement of files around for example.

That’s true with any of these additive/subtractive robots… and good advice…

Wow. I thought I understood G code from 3D printing / laser work and was ready to build an LR3.

LOL I don’t know crap about the coordinate systems.

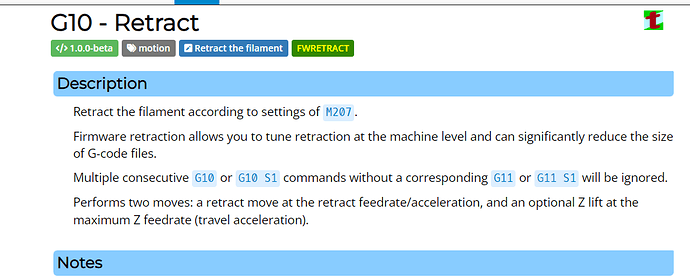

G10 is a retract (!!??!!) ahh, that’s why it seemed funky to me when reading this thread.

Why would Marlin repurpose things this way?